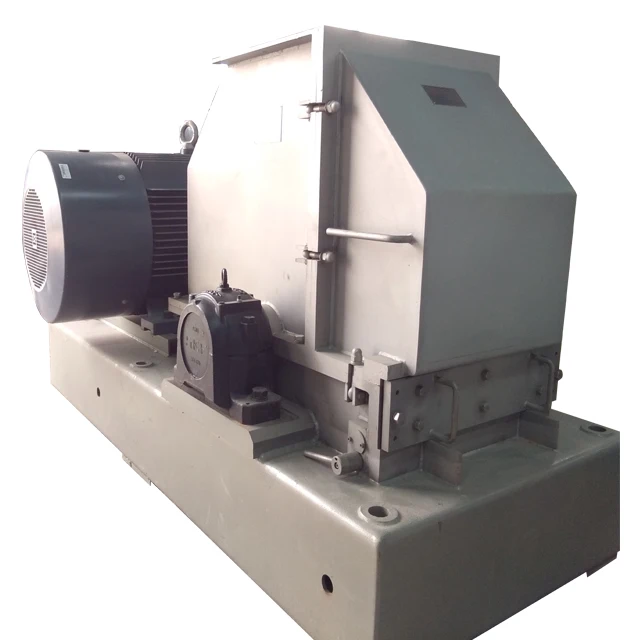

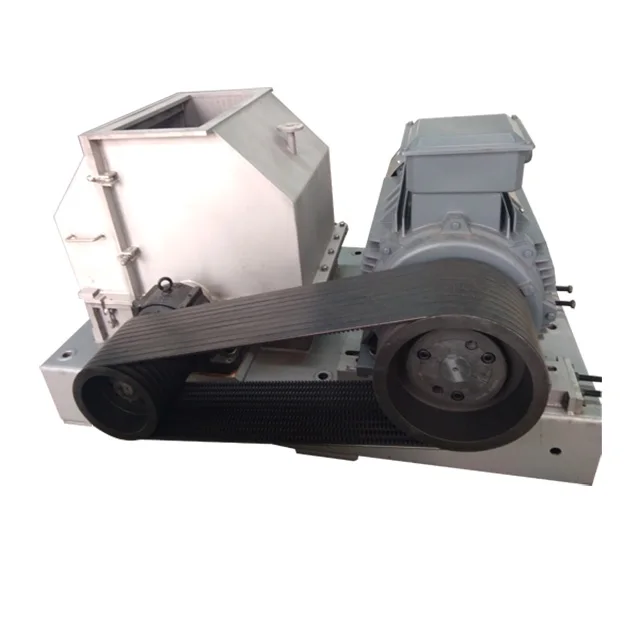

Патент птодукт маниока точильщика мельница машина Терка 250 кВт rasper fufu производитель делающих

- Категория: Flour Mill >>>

- Поставщик: Zhengzhou,Jinghua,Industry,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 41115.32 $* | 43171.88 $* |

| Aug-17-2025 | 40769.60 $* | 42807.81 $* |

| Jul-17-2025 | 34205.65 $* | 35915.79 $* |

| Jun-17-2025 | 40078.5 $* | 42082.2 $* |

| May-17-2025 | 34896.78 $* | 36641.14 $* |

| Apr-17-2025 | 39387.26 $* | 41356.16 $* |

| Mar-17-2025 | 39042.70 $* | 40994.19 $* |

| Feb-17-2025 | 38696.69 $* | 40631.10 $* |

| Jan-17-2025 | 38351.94 $* | 40269.23 $* |

Характеристики

Introduction of fufu pounding machine

The rasper high speed crushing raw materials, destroy the fiber structure, starch particles free, for the company's high-tech products and patented technology products. Widely used in canna, cassava, potato and other materials such as secondary grinding.

Key Technology & Innovation Potions

1. All parts in contact with raw material are made of food-grade stainless steel, which protects materials from outer pollution.

2. High rotating speed, high line speed, excellent rasping performance, uniform particle, and high starch ionization rate.

3. Rotor is calibrated with international advanced dynamic-balance instrument, meeting G1 standard.

4. Components(bearings for example) are imported from Europe with longer service life

5. Unique sieve-tension gear makes disassembly easy.

Main technical parameters

Model | DCM8435 | DCM8450 | DCM8465 | DCM1070 |

Main shaft rotating speed(r/min) | 2100 | 2100 | 2100 | 1470 |

Drum diameter (mm) | Φ840 | Φ840 | Φ840 | Φ1100 |

Drum width (mm) | 350 | 500 | 650 | 700 |

Power (Kw) | 110 | 160 | 200 | 250 |

Capacity (t/h) | 20-23 | 30-33 | 35-40 | 40-45 |

Dimension(mm) | 2170x1260x1220 | 2170x1385x1250 | 2170x1650x1380 | 3000x1590x1500 |

Structure introduction

Complete machine consists of rotor, rasping blade, engine base, upper cover, side cover, bearing base, gearing, motor, etc.

1. Engine base props up all components, which rotor and bearings are all fixed on.

2. Rotor is made of special stainless steel, uniform grooves on the surface to install saw blade.

3. Saw blade is comprised of 2 stainless-steel layer with locating pin and a saw blade.

4. 2 combined rasping blade are equipped on both side of rotor, which could achieve rotor two-way rotating and crests higher crushing rate.

5. A sieve is equipped between rasping blades, which is tensioned by two sets tensioning instruments.

The working principle of rasper

The material enters into the body of the file mill shell through the upper entrance, and is broken by the impact, shear and grinding effect of the saw blade moving at high speed. The lower part of the rotor is equipped with a screen screen. The material smaller than the size of the screen hole is discharged through the screen plate, and the particles larger than the size of the screen hole are blocked and remain on the screen plate to continue to be hit and grinder by the saw blade.

Real application case

Fufu is a popular staple food in West and Central Africa made out of cassava, plantains or yams. The improved production process is starts by peeling of roots, washing, cutting into pieces and steeping in water to ferment for 3-4 days. The fermented mash is pounded or simply washed over a fine sieve to remove fibre and the water expelled from the starch extract by pressing through muslin cloth to produce fufu.

Pre-sale service

1.Accept customer consultation and customize products according to customer requirements.

2.Provide customers with product process, equipment parameters and processes, and train personnel according to customer requirements.

Sale service

1.The company sent technical personnel to the scene of the on-the -spot guidance equipment installation,debugging and training operators.

2.If there is any problem during the installation, please contact the responsible person in time. We will solve the problem in time to ensure the installation progress.

After-sale service

1.Provide telephone and video support. If the customer has any problems or abnormal devices in use, you can contact us by phone. We will help the customer solve the problems by phone or video.

2.If the phone or video doesn't work, the company will send technicians to the scene to fix the problem.

3.Products purchased in our company, we provide one-year warranty and lifelong maintenance service.

Packing & Shipping: Customize the wooden case according to the size of the product.

Delivery: 14 days after receiving pre-payment (on time according to contract strictly).

Zhengzhou Jinghua Industry Co.,Ltd. is a professional starch engineering corporation in China. Depending on the unique advantage and strong strength of Henan University of Technology, Jinghua combines scientific research, industry and trade as a whole, which mainly engaged in the working of factory layout, technology design,complete equipment manufacturing and commissioning, new product developing etc. to all kinds starch processing. Has two modern large factory, engineering and technical personnel more than 30 people, can provide installation services overseas. Our company has undertaken national and provincial scientific research projects.,with more than 30 invention patents, various honor certificate more than 20.

Zhengzhou jinghua industrial co., LTD., as a member of China starch industry association, was invited to attend the 2019 Shanghai international starch and starch derivatives exhibition. In this meeting, zhengzhou jinghua industry co., ltd. and the new and old customers in-depth meeting exchanges, for the future further cooperation to create a good beginning, to the whole industry to show the recent new research and development results, harvested from more peers and experts unanimously recognized.

Q1: Can you provide detailed parameters and drawings of the equipment?

A: Yes, you can contact us by email, we will provide you with the detailed parameters and drawings of the equipment.

Q2:How long is the warranty period of the equipment?

A:After the successful installation and commissioning of the equipment, there is a one-year warranty period.

Q3:What kind of after-sales service do you provide?

A:Provide after-sales service for customers through telephone, video guidance, on-site maintenance, etc.

Q4: Are your products can be assured ?

A: Our machines are all have CE certificate by SGS, TUV.

Q5: If we show you our layout of factory, can you help us to design the whole process line?

A : Yes, our experienced engineers and technical employees can help you to arrange the layout and installation of whole process line based on your real situation;

Q6: If we have samples of new products, can you help us to analysis and design the machine?

A: Yes, Our technical department can help you to analysis, design and test the new products you offered.

Zhengzhou Jinghua Industry Co.,Ltd.

Add:Guanggu Road, Xingyang City,Henan Province,China