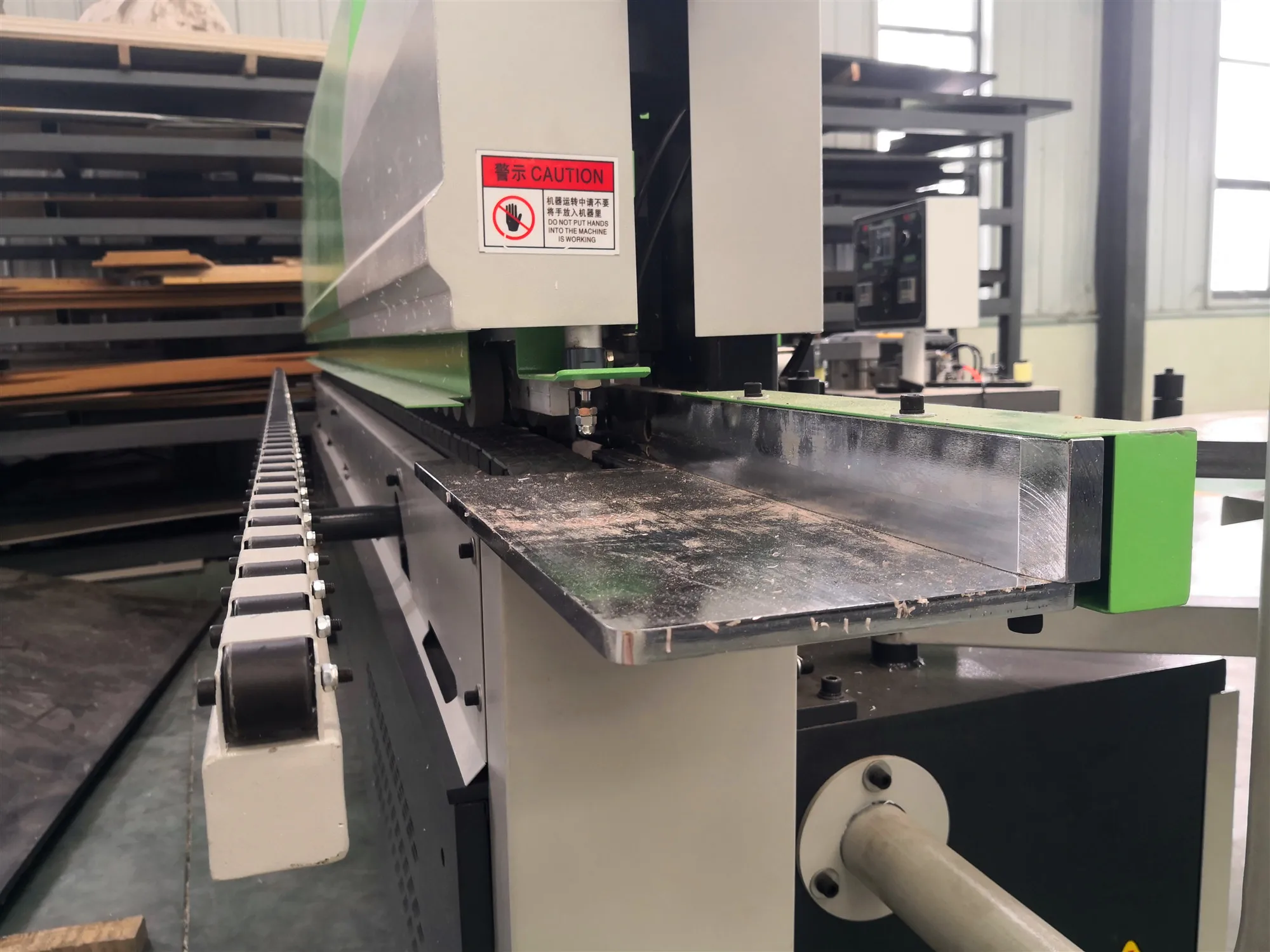

Автоматическая машина для облицовки кромок древесины МДФ

- Категория: Wood Based Panels Machinery >>>

- Поставщик: Spower,Machinery,Technology,Co.,Ltd.(Jinan)

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 3570.93 $* | 3749.13 $* |

| Aug-20-2025 | 3540.78 $* | 3717.16 $* |

| Jul-20-2025 | 2970.41 $* | 3119.11 $* |

| Jun-20-2025 | 3480.23 $* | 3654.30 $* |

| May-20-2025 | 3030.9 $* | 3182.11 $* |

| Apr-20-2025 | 3420.26 $* | 3591.41 $* |

| Mar-20-2025 | 3390.97 $* | 3560.49 $* |

| Feb-20-2025 | 3360.41 $* | 3528.98 $* |

| Jan-20-2025 | 3330.62 $* | 3497.41 $* |

Характеристики

Product Description

Pre-Milling →Glue →Straight Pressure Welt →End Trimming →Rough Trimming →Pneumatic Fine Trimming →Corner Trimming →Scraping →Buffing

Specification

Configuration | Standard Parameter for BCM506 |

Product Name | Automatic Linear Edge Banding Machine |

Model | BCE506 |

Motor power | 11.13kw |

Feed speed | 12-20m/min |

Voltage | 380V/50HZ/3Phase |

Application | Kitchen Cabinet, Panel furniture,Wooden cabinet |

Panel Thickness | 10~60mm |

Edge Thickness | 0.4-3mm |

Feeding speed | 12-20m/min |

Panel Width | ≥80mm |

Band Thickness | 0.3~3.0mm |

Air Pressure | 6kg |

Details Images

Delta Controller

Gluing

The hot melt glue is heated by the glue pot, and adopts spiral structure.The sheet and the edge banding material are evenly glued, and the edge band and the sheet are pressed tightly through the pressing wheel to make the adhesion stronger

End cutting

Rough Trimming &Fine Trimming

Corner Trimming

Buffing

Applications&Samples

The edge banding machine is mainly used for various man-made boards such as medium density fiberboard, blockboard, solid wood board, particle board, polymer door panel, plywood, etc., and is widely used in panel furniture, cabinets and other furniture industries.

Main effect:

1. Beautiful and decorative

It is beautiful and generous by using boards of different colors with different color edge bands. And the sealing edge is exquisite, smooth, and feels good, and the sealing line is straight and smooth

2. Protect the board

Adhesive is also needed between the edge banding and the furniture board. This way of strengthening from the side makes the board not easy to crack. The edge banding can effectively prevent the board from getting damp

Main effect:

1. Beautiful and decorative

It is beautiful and generous by using boards of different colors with different color edge bands. And the sealing edge is exquisite, smooth, and feels good, and the sealing line is straight and smooth

2. Protect the board

Adhesive is also needed between the edge banding and the furniture board. This way of strengthening from the side makes the board not easy to crack. The edge banding can effectively prevent the board from getting damp

Related Products

Our Service

1. For whole edge banding machine, we provide 1-2 years warranty and lifetime after-sales service, we will provide the consumable parts at an agency price when you need replacement.

2. Main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

3. Our engineer could support you technology to your country if necessary.

4.Our engineer could service you 24 hours online by Skype, yahoo, msn, QQ, or by cellphone.

5. English manual and CD video for machine using and maintaining will send to you with the machine.

2. Main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

3. Our engineer could support you technology to your country if necessary.

4.Our engineer could service you 24 hours online by Skype, yahoo, msn, QQ, or by cellphone.

5. English manual and CD video for machine using and maintaining will send to you with the machine.

Company Profile