8 33-9 90 мм высокоскоростной стальной инструмент для снятия

- Категория: Other Cutting & Forming Tools >>>

- Поставщик: Tanran,Intelligent,Technology,(Changzhou),Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 38.44 $* | 40.18 $* |

| Aug-18-2025 | 38.67 $* | 40.15 $* |

| Jul-18-2025 | 32.54 $* | 34.58 $* |

| Jun-18-2025 | 37.86 $* | 39.48 $* |

| May-18-2025 | 32.67 $* | 34.21 $* |

| Apr-18-2025 | 36.92 $* | 38.46 $* |

| Mar-18-2025 | 36.78 $* | 38.54 $* |

| Feb-18-2025 | 36.97 $* | 38.85 $* |

| Jan-18-2025 | 36.44 $* | 38.72 $* |

Характеристики

Product Paramenters

Inner Hole Deburring chamfer Cutting Tool | ||||||

Product Name | Inner hole deburring and chamfering cutting tool | |||||

Workpiece Material | Hardness lower than HRC25 | |||||

Application | Aviation, military, automotive industry parts, engine cylinder, cylinder, ball through the hole, the inner wall hole | |||||

Sample | Yes | Type | Deburring Chamfer Tool | |||

Stock | Yes | Raw Material | High-Speed Steel | |||

OEM/ODM | Yes | Coating | No Coating | |||

The tool design is simple, efficient and stable. No complicated or time-consuming presetting process. Diameter of the hole determines the cutter size. You need to provide the following dimensions:

Item1 | Machining workpiece aperture and depth size, and the structure of the workpiece | ||||||

Item2 | Material of the workpiece | ||||||

Item3 | Processing requirements: deburring or chamfering | ||||||

Item4 | Machine tools | ||||||

Product Description

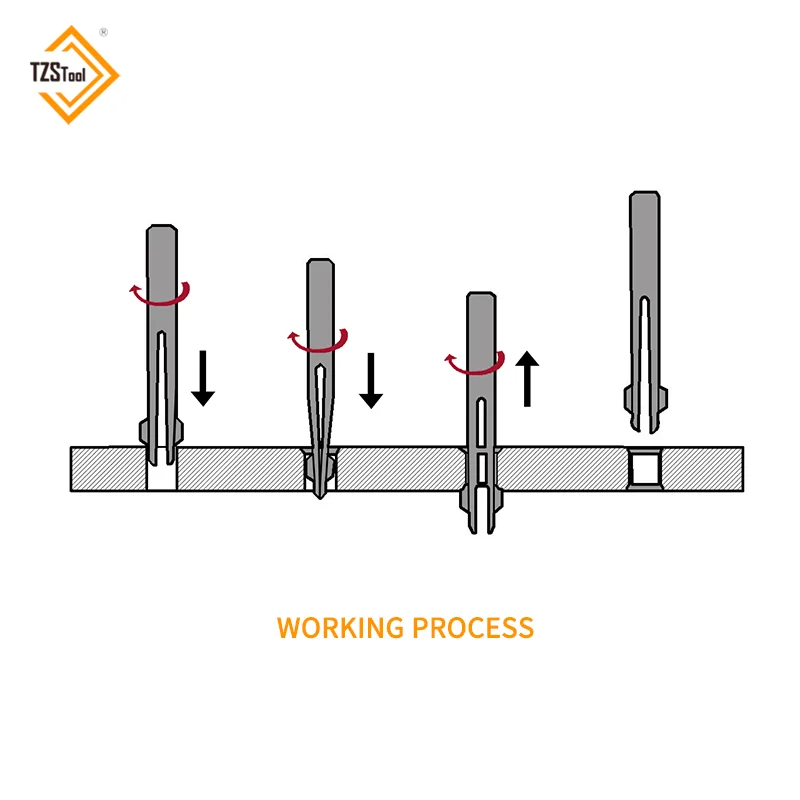

How to solve the problem of deburring and chamfering:

Question | Answer | ||||||

Will it scratch or enlarge the inner hole | Many customers concern if the cutter will scratch or enlarge the inner hole. Actually, we don’t need to worry about it at all. In order to guarantee the production efficiency, the cutter can be rotated into the whole hole. Unless the inner hole surface roughness reach at Ra0.8, the inner hole will not be affected at all (Aluminum or copper pieces need to choose smaller bore diameter, for example, to process aluminum workpiece 3.2, it’s better to choose 2.8~3.18 ). | ||||||

The chamfering size is too small, and the burrs can’t be removed | 1. Whether the tool model is too small 2. Rotate speed and feed need to be retest | ||||||

The chamfering size is too large | 1. Feed is too small 2. The tool model is too large 3. The blade force is too strong(the blade strength of the split deburring and chamfering cutter can be adjusted by itself) | ||||||

The working life is too short | 1. Workpiece or tool clamp is fixed tightly 2. Machine tool is not stable(axial wear, etc) 3. Workpiece hardness is too high(the cutter can be applied to the workpiece with hardness lower than HRC30) | ||||||

Contact Us

Phone: | +86 18961463707 | ||||||

Email: | mona.du@tzstool.com | ||||||

Whatsapp: | +86 18961463707 | ||||||

Wechat: | +86 18961463707 | ||||||

Website: | www.tzstools.com/EN | ||||||

Skype: | 237010162@qq.com | ||||||

Address: | No.53, Zhennan West Road, Xixiashu, Xinbei, Changzhou,Jiangsu,China 213114 | ||||||