Ali baba китайский производитель тонкая медная труба латунная проволочная

- Категория: Проволочноволочильные станки >>>

- Поставщик: Wuxi,Jintong,Furnace,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.63 $* | 0.86 $* |

| Aug-19-2025 | 0.29 $* | 0.36 $* |

| Jul-19-2025 | 0.98 $* | 0.78 $* |

| Jun-19-2025 | 0.21 $* | 0.30 $* |

| May-19-2025 | 0.96 $* | 0.28 $* |

| Apr-19-2025 | 0.65 $* | 0.53 $* |

| Mar-19-2025 | 0.93 $* | 0.65 $* |

| Feb-19-2025 | 0.14 $* | 0.81 $* |

| Jan-19-2025 | 0.4 $* | 0.63 $* |

Характеристики

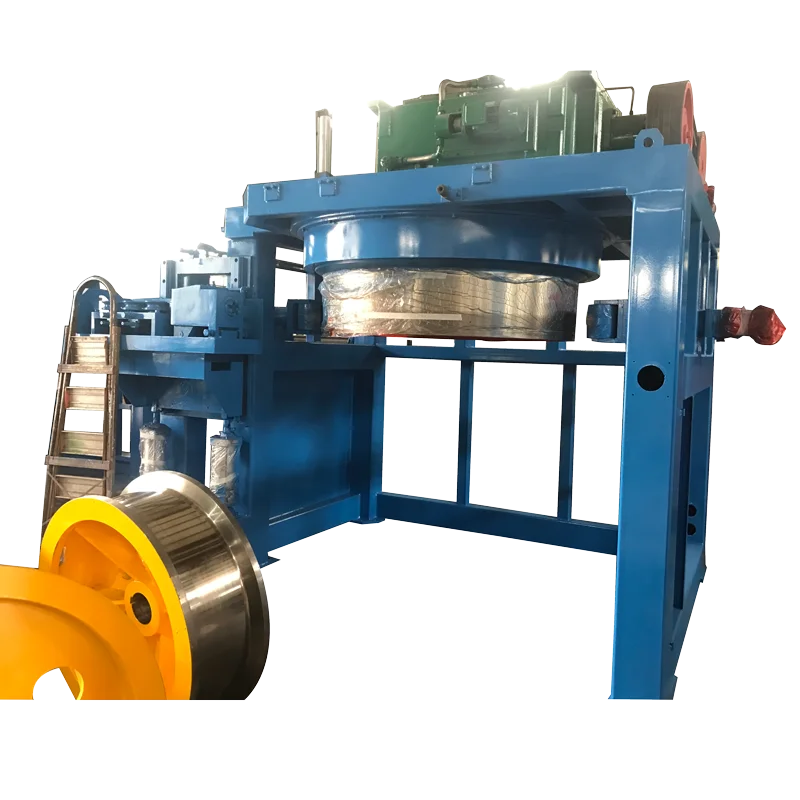

Pancake Coil Spinner Block Solution

Max. Feeding OD: 25mm, Length: 60M

Min. Finishing OD: 6.5mm, Length:600-700M

Specifications:

A. LDD-1500 Inverted Drawing Machine (with straightener unit)

1. Equipment use: for the stretching production of copper pipes and the inverted winding.

2. Processing materials: copper pipe

3. 1. The maximum size of incoming diameter is 25mm, and outgoing diameter is 16mm

3. 4. Drum diameter: 1500 mm

3. 5. Number of drum: 1 drum (inverted installation)

3. 6. Drum material: bead weld of working surface, bead weld thickness 3~4mm, working wheel surface polishing processing, drum hardness: HRC55~56° roughness ≤0.4,

3. 7. Drum cooling: water cooling circulation

3. 8. and drawing time: 1 n

3. 9. Inlet method: with straightening device

3. 10. Mould lubrication way: soak + spray method

4. Stretching speed: maximum drawing speed 50 m/min

5, Main motor power: 55 kw

6, frequency control of motor speed : variable-frequency control

7, Coiling method: Simplex retract

8, The car motor: 5.5 KW

9, Coiling weight : 2000 kg/plate

10, With a full set of electrical control

Specifications:

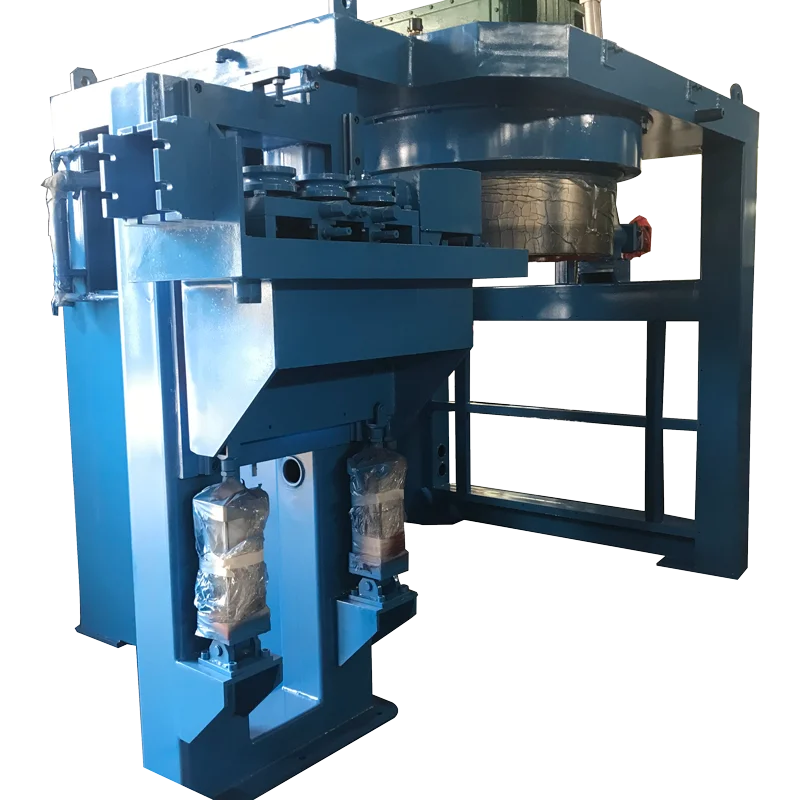

A. LDD-1000 Inverted Drawing Machine (with straightener unit)

1. Equipment use: for the stretching production of copper pipes and the inverted winding.

2. Processing materials: copper pipe

3. 1. The maximum size of incoming diameter is 16mm, and outgoing diameter is 10mm

3. 4. Drum diameter: 1000 mm

3. 5. Number of drum: 1 drum (inverted installation)

3. 6. Drum material: bead weld of working surface, bead weld thickness 3~4mm, working wheel surface polishing processing, drum hardness: HRC55~56° roughness ≤0.4,

3. 7. Drum cooling: water cooling circulation

3. 8. and drawing time: 1 n

3. 9. Inlet method: with straightening device

3. 10. Mould lubrication way: soak + spray method

4. Stretching speed: maximum drawing speed 75m/min

5, Main motor power: 30kw

6, frequency control of motor speed : variable-frequency control

7, Coiling method: Simplex retract

8, The car motor: 4 KW

9, Coiling weight : 1800 kg/plate

10, With a full set of electrical control

Specifications:

A. LW-750 vertical single drum tube drawing machine

1, the drawing material: copper tube

2, drum diameter: 750 mm

3, roll material: cast steel heat treatment grinding processing

4. The inlet line shall require a five-wheel straightening device for the

limit of the inlet line

5, transmission mode gear + triangle belt transmission

6. Four screw rods are required for reels

7, protection requirements with guardrail device

8 Tube inlet OD: 12 ~ 8 mm

9, the drawing speed: 40 ~ 60 m/min

10, 22 kw motor power

11, regulating mode frequency conversion speed regulation

Q. What is your MOQ?

A. 1 set.

Q. Your company is a trading firm? or Factory?

A. We are a factory with 10+ years experience in industrial melting feild. We currently have three branches: main frequency furnace production, medium frequency furnace production, component machine production. You are warmly welcomed to visit our factories.

Q. How is your products quality?

A. As a manufacturer, we have our own R&D team. Basing on several years of technical innovation, we have accumulated successful experience in induction heating, temperature holding, fast melting. We've customized so many furnaces with all positive feedbacks.

Q. What kind of material our furnace can melting?

A. Jintong is able to supply a melting production line such as copper/zinc/aluminum melting line.Jintong medium frequency furnace can also melt iron, steel, gold, silver and so on.

Q. I am not so familiar with your machine now. I am not sure I can use it well if I buy it from you.

A. Don't worry about this. With the machine, we will send you a brochure with detailed information of our machine operation. In addition, we will send you videos of machine set up and using. Our engineers are always available for consultation. Engineers can support at your place if it is needed.