T12 жало паяльника жала-дюймовые сверла для сверления OLED контроллер 951 952 956 паяльная станция FX-9501 Сварка

- Категория: Наконечники сварочной горелки >>>

- Поставщик: Shenzhen,Weishang,Power,Network,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 2.37 $* | 2.87 $* |

| Aug-18-2025 | 2.2 $* | 2.36 $* |

| Jul-18-2025 | 2.16 $* | 2.15 $* |

| Jun-18-2025 | 2.42 $* | 2.33 $* |

| May-18-2025 | 2.56 $* | 2.26 $* |

| Apr-18-2025 | 2.53 $* | 2.65 $* |

| Mar-18-2025 | 2.94 $* | 2.90 $* |

| Feb-18-2025 | 2.23 $* | 2.30 $* |

| Jan-18-2025 | 2.84 $* | 2.27 $* |

Характеристики

Product Description

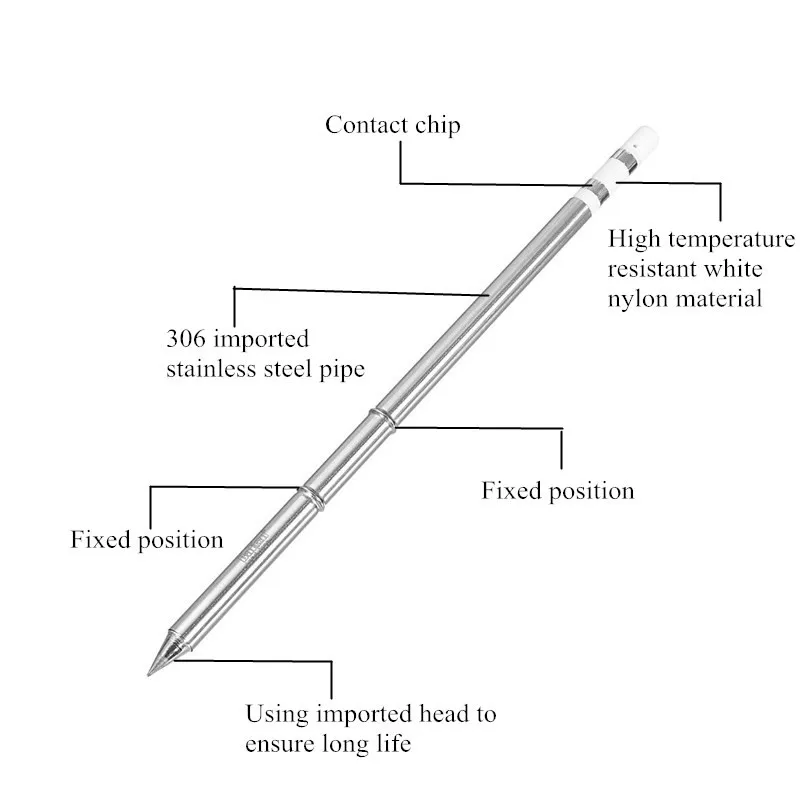

Specification

Lenght | 139mm |

product series | T12 |

Scope of application | All standard T12 soldering stations |

Warranty solder joints | 30000 |

Packing & Delivery

Please contact us before you make order !

This product is QUICKO brand T12 serirs of welding tips, this kind of tips can only be used on T12 series of iron handle and

station, such as HAKKO FX-9501 FM-2028 handle/ HAKKO FX-951 solder station/ QUICKO T12-9501handle QUICKO T12-951 / 952 station and

other brand of T12 DIY iron stations.

This product is QUICKO brand T12 serirs of welding tips, this kind of tips can only be used on T12 series of iron handle and

station, such as HAKKO FX-9501 FM-2028 handle/ HAKKO FX-951 solder station/ QUICKO T12-9501handle QUICKO T12-951 / 952 station and

other brand of T12 DIY iron stations.

Company Profile

FAQ:

1. Why the temperature of the new T12 solder tip is jump?

Because the inside heating core of the new T12 solder tip did not go through the high temperature, so the first time to use will be a bit of temperature, generally without special treatment, the normal use of 1-2 days after the basic will not bounce. Such as the need to immediately effective, the general proposal to adjust the temperature to 380 degree -400 degree, side of the solder tip to the tip of tin, burning 5-10 minutes after the shutdown, until the solder tip of the cooling and then re-boot! ( if 1 times no effect, then can be repeated 2-3 times). T12 is pulsating temperature warming, even if the display temperature is flashing, the tip of the real temperature is completely stable.

T12 jump temperature also are connected with the temperature control board of procedures, power of electrostatic and if it connect the ground.

2. What the problem of attention when we use the T12 first time?

T12 tip heating speed is very fast, when the new solder tip connect the electricity, it must be tinput immediately to the solder tip, for protection, due to heating up fast, just need 6-10 seconds, no have more time to you for preparetion.

so the important is prepare the items which will be welded, and finally boot power, and each welding gap or the end, should be more on the tin to protect and then shutdown, so it can avoid to tin the new sold tip is difficult, especially the T12 tip type of iron, such as T12-I / T12-IL / T12-BL / T12-ILS and so on!

3.What are the precautions for using the T12 tip?

a. If can use low temperature, then do not high temperature: T12 is constant temperature control, the general recommended working temperature control between 300 degree- 380 degree, higher than 380 degree damage the coating of solder tip and cut down the PTC life!

b. Do not dry: the first time to use solder tip, should be wrapped while heating a layer of tin. If it's without work, at once shutdown!

c. Diligent to clean: before shutting down, use a wet sponge or detin the ball to remove the tip of the oxidation of debris, on the tin after the shutdown power off!

d. Standard operation: Do not violent collision the solder tip, do not stamp the top of the hard objects, but can not be used to hot plastic and other materials, specifically reminded that friends like tin should avoid the iron and other hard metal knock tin, the heating core of T12 is in the head of the solder tip, often percussion is a fatal damage to T12!

e. Less use of scaling powder: scaling powder can not be used, can be used as less as possible! When scaling powder help make beautiful and reliable welding at the same time, but also greatly speed up the consumption the coating of the solder tip, T12 heating core high temperature position is very near of the Nozzle tip of the solder tip,Scaling powder in the fear of threat to T12 head pressing parts.

1. Why the temperature of the new T12 solder tip is jump?

Because the inside heating core of the new T12 solder tip did not go through the high temperature, so the first time to use will be a bit of temperature, generally without special treatment, the normal use of 1-2 days after the basic will not bounce. Such as the need to immediately effective, the general proposal to adjust the temperature to 380 degree -400 degree, side of the solder tip to the tip of tin, burning 5-10 minutes after the shutdown, until the solder tip of the cooling and then re-boot! ( if 1 times no effect, then can be repeated 2-3 times). T12 is pulsating temperature warming, even if the display temperature is flashing, the tip of the real temperature is completely stable.

T12 jump temperature also are connected with the temperature control board of procedures, power of electrostatic and if it connect the ground.

2. What the problem of attention when we use the T12 first time?

T12 tip heating speed is very fast, when the new solder tip connect the electricity, it must be tinput immediately to the solder tip, for protection, due to heating up fast, just need 6-10 seconds, no have more time to you for preparetion.

so the important is prepare the items which will be welded, and finally boot power, and each welding gap or the end, should be more on the tin to protect and then shutdown, so it can avoid to tin the new sold tip is difficult, especially the T12 tip type of iron, such as T12-I / T12-IL / T12-BL / T12-ILS and so on!

3.What are the precautions for using the T12 tip?

a. If can use low temperature, then do not high temperature: T12 is constant temperature control, the general recommended working temperature control between 300 degree- 380 degree, higher than 380 degree damage the coating of solder tip and cut down the PTC life!

b. Do not dry: the first time to use solder tip, should be wrapped while heating a layer of tin. If it's without work, at once shutdown!

c. Diligent to clean: before shutting down, use a wet sponge or detin the ball to remove the tip of the oxidation of debris, on the tin after the shutdown power off!

d. Standard operation: Do not violent collision the solder tip, do not stamp the top of the hard objects, but can not be used to hot plastic and other materials, specifically reminded that friends like tin should avoid the iron and other hard metal knock tin, the heating core of T12 is in the head of the solder tip, often percussion is a fatal damage to T12!

e. Less use of scaling powder: scaling powder can not be used, can be used as less as possible! When scaling powder help make beautiful and reliable welding at the same time, but also greatly speed up the consumption the coating of the solder tip, T12 heating core high temperature position is very near of the Nozzle tip of the solder tip,Scaling powder in the fear of threat to T12 head pressing parts.

FAQ

FAQ:

1. Why the temperature of the new T12 solder tip is jump?

Because the inside heating core of the new T12 solder tip did not go through the high temperature, so the first time to use will be a bit of temperature, generally without special treatment, the normal use of 1-2 days after the basic will not bounce. Such as the need to immediately effective, the general proposal to adjust the temperature to 380 degree -400 degree, side of the solder tip to the tip of tin, burning 5-10 minutes after the shutdown, until the solder tip of the cooling and then re-boot! ( if 1 times no effect, then can be repeated 2-3 times). T12 is pulsating temperature warming, even if the display temperature is flashing, the tip of the real temperature is completely stable.

T12 jump temperature also are connected with the temperature control board of procedures, power of electrostatic and if it connect the ground.

2. What the problem of attention when we use the T12 first time?

T12 tip heating speed is very fast, when the new solder tip connect the electricity, it must be tinput immediately to the solder tip, for protection, due to heating up fast, just need 6-10 seconds, no have more time to you for preparetion.

so the important is prepare the items which will be welded, and finally boot power, and each welding gap or the end, should be more on the tin to protect and then shutdown, so it can avoid to tin the new sold tip is difficult, especially the T12 tip type of iron, such as T12-I / T12-IL / T12-BL / T12-ILS and so on!

3.What are the precautions for using the T12 tip?

a. If can use low temperature, then do not high temperature: T12 is constant temperature control, the general recommended working temperature control between 300 degree- 380 degree, higher than 380 degree damage the coating of solder tip and cut down the PTC life!

b. Do not dry: the first time to use solder tip, should be wrapped while heating a layer of tin. If it's without work, at once shutdown!

c. Diligent to clean: before shutting down, use a wet sponge or detin the ball to remove the tip of the oxidation of debris, on the tin after the shutdown power off!

d. Standard operation: Do not violent collision the solder tip, do not stamp the top of the hard objects, but can not be used to hot plastic and other materials, specifically reminded that friends like tin should avoid the iron and other hard metal knock tin, the heating core of T12 is in the head of the solder tip, often percussion is a fatal damage to T12!

e. Less use of scaling powder: scaling powder can not be used, can be used as less as possible! When scaling powder help make beautiful and reliable welding at the same time, but also greatly speed up the consumption the coating of the solder tip, T12 heating core high temperature position is very near of the Nozzle tip of the solder tip,Scaling powder in the fear of threat to T12 head pressing parts.

1. Why the temperature of the new T12 solder tip is jump?

Because the inside heating core of the new T12 solder tip did not go through the high temperature, so the first time to use will be a bit of temperature, generally without special treatment, the normal use of 1-2 days after the basic will not bounce. Such as the need to immediately effective, the general proposal to adjust the temperature to 380 degree -400 degree, side of the solder tip to the tip of tin, burning 5-10 minutes after the shutdown, until the solder tip of the cooling and then re-boot! ( if 1 times no effect, then can be repeated 2-3 times). T12 is pulsating temperature warming, even if the display temperature is flashing, the tip of the real temperature is completely stable.

T12 jump temperature also are connected with the temperature control board of procedures, power of electrostatic and if it connect the ground.

2. What the problem of attention when we use the T12 first time?

T12 tip heating speed is very fast, when the new solder tip connect the electricity, it must be tinput immediately to the solder tip, for protection, due to heating up fast, just need 6-10 seconds, no have more time to you for preparetion.

so the important is prepare the items which will be welded, and finally boot power, and each welding gap or the end, should be more on the tin to protect and then shutdown, so it can avoid to tin the new sold tip is difficult, especially the T12 tip type of iron, such as T12-I / T12-IL / T12-BL / T12-ILS and so on!

3.What are the precautions for using the T12 tip?

a. If can use low temperature, then do not high temperature: T12 is constant temperature control, the general recommended working temperature control between 300 degree- 380 degree, higher than 380 degree damage the coating of solder tip and cut down the PTC life!

b. Do not dry: the first time to use solder tip, should be wrapped while heating a layer of tin. If it's without work, at once shutdown!

c. Diligent to clean: before shutting down, use a wet sponge or detin the ball to remove the tip of the oxidation of debris, on the tin after the shutdown power off!

d. Standard operation: Do not violent collision the solder tip, do not stamp the top of the hard objects, but can not be used to hot plastic and other materials, specifically reminded that friends like tin should avoid the iron and other hard metal knock tin, the heating core of T12 is in the head of the solder tip, often percussion is a fatal damage to T12!

e. Less use of scaling powder: scaling powder can not be used, can be used as less as possible! When scaling powder help make beautiful and reliable welding at the same time, but also greatly speed up the consumption the coating of the solder tip, T12 heating core high temperature position is very near of the Nozzle tip of the solder tip,Scaling powder in the fear of threat to T12 head pressing parts.