Удобный сварочный аппарат TRINTFAR для стыковых

- Категория: Стыковой сварочный аппарат >>>

- Поставщик: Shanghai,Trintfar,Intelligent,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.97 $* | 0.38 $* |

| Aug-19-2025 | 0.78 $* | 0.70 $* |

| Jul-19-2025 | 0.72 $* | 0.5 $* |

| Jun-19-2025 | 0.62 $* | 0.41 $* |

| May-19-2025 | 0.44 $* | 0.29 $* |

| Apr-19-2025 | 0.17 $* | 0.11 $* |

| Mar-19-2025 | 0.26 $* | 0.51 $* |

| Feb-19-2025 | 0.50 $* | 0.13 $* |

| Jan-19-2025 | 0.91 $* | 0.7 $* |

Характеристики

Introduction

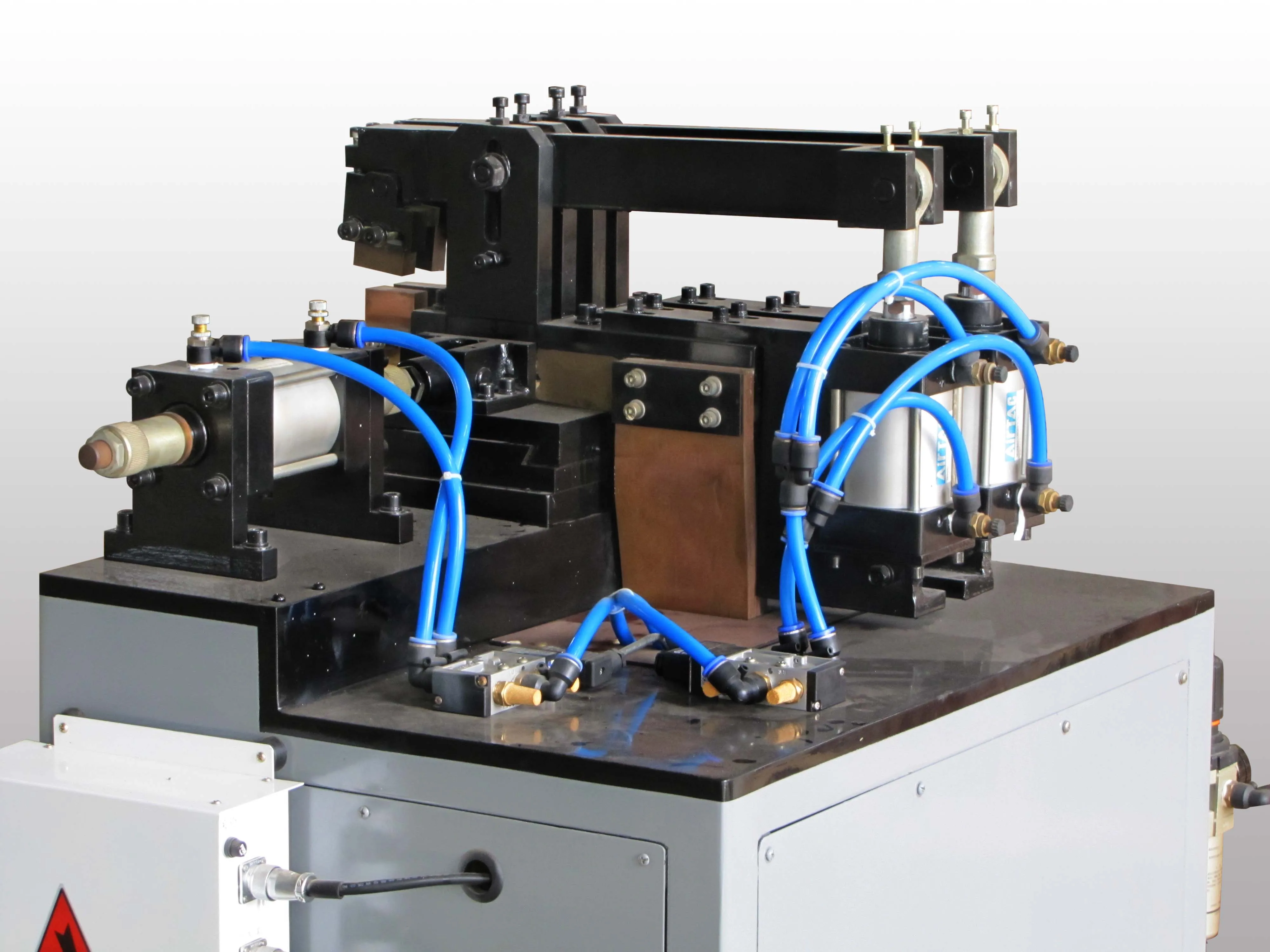

The parts to be butt welded are pneumatically and hydraulically controlled to provide an even flash contact at the contact edges. initiaIly the power is turned on and progressively increased to remove oxidants and residues. The end surfaces of the parts to be welded are heated to plastic stage through a regulated power supply. Upset forging force is then applied to make the end surfaces to get flushed and welded. The machine is designed to provide the high welding strength to the welded component. There is no false joint, residue and air bubble in the point of welding.The machine is widely used in the butt welding of handles of kitchen utensils such as knife, fork, spoon and spatula, as well as the welding of hardware products such as round pipes, square pipes, round steel, flat iron, bicycle wheel rims, motor wheel rims, etc.

Feature

- By integration of electromechanical, hydraulic and pneumatic design, the warming up, flashing and upset forging process are optimized to have best result.

- Controlled by microprocessor, has various series specification storage, valid for different working parts welding.

Item Model | UN-25 | UN-35 | UN-50 | UN-75 | UN-100 | UN-150 | UN-200 |

Rated capacity |

25 |

35 |

|

75 |

100 |

150 |

200 |

Rated Primary voltage V |

380 |

380 |

380 |

380 |

380 |

380 |

380 |

Rated frequency Hz |

50/60 |

50/60 |

|

|

50/60 |

|

50/60 |

Maximum short current A |

11000 |

|

15000 |

|

28000 |

32000 |

35000 |

Maximum clamping rate N |

|

|

3900 |

6100 |

|

8000 |

8000 |

Maximum forging force N |

1500 |

1500 |

1500 |

2500 |

2500 |

3000 |

3000 |

Rated duty cycle % |

50 |

50 |

50 |

50 |

50 |

50 |

50 |

Application

It can applied to iron wire products, hardware decorative lighting, kitchen utensils, small household appliances, small hardware, etc.