Высококачественный Профессиональный ламинатор 720 мм A3 A4 для горячего и холодного

- Категория: Ламинатор >>>

- Поставщик: Guangzhou,Disen,Electromechanical,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 1726.62 $* | 1812.62 $* |

| Aug-19-2025 | 1711.56 $* | 1797.26 $* |

| Jul-19-2025 | 1436.92 $* | 1508.28 $* |

| Jun-19-2025 | 1682.59 $* | 1766.19 $* |

| May-19-2025 | 1465.72 $* | 1538.64 $* |

| Apr-19-2025 | 1653.2 $* | 1736.85 $* |

| Mar-19-2025 | 1639.22 $* | 1721.11 $* |

| Feb-19-2025 | 1624.48 $* | 1705.2 $* |

| Jan-19-2025 | 1610.24 $* | 1691.70 $* |

Характеристики

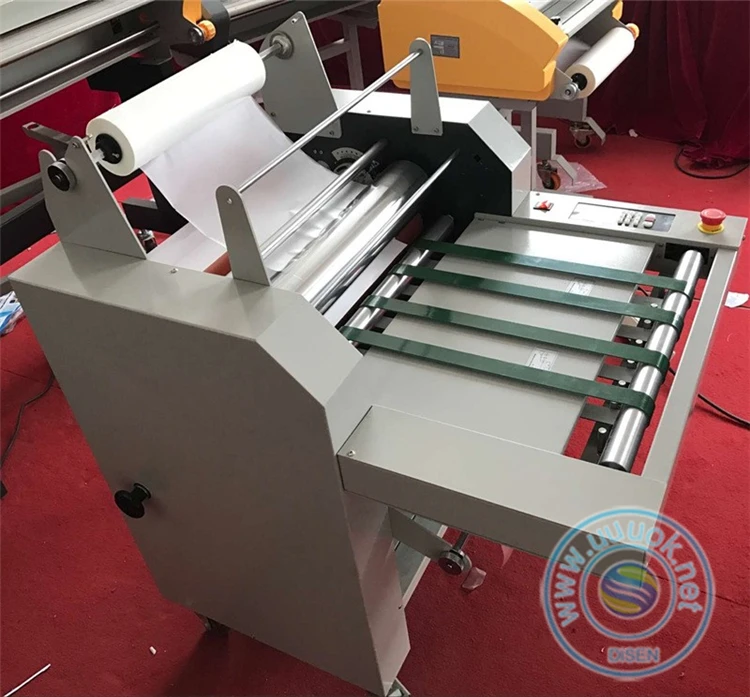

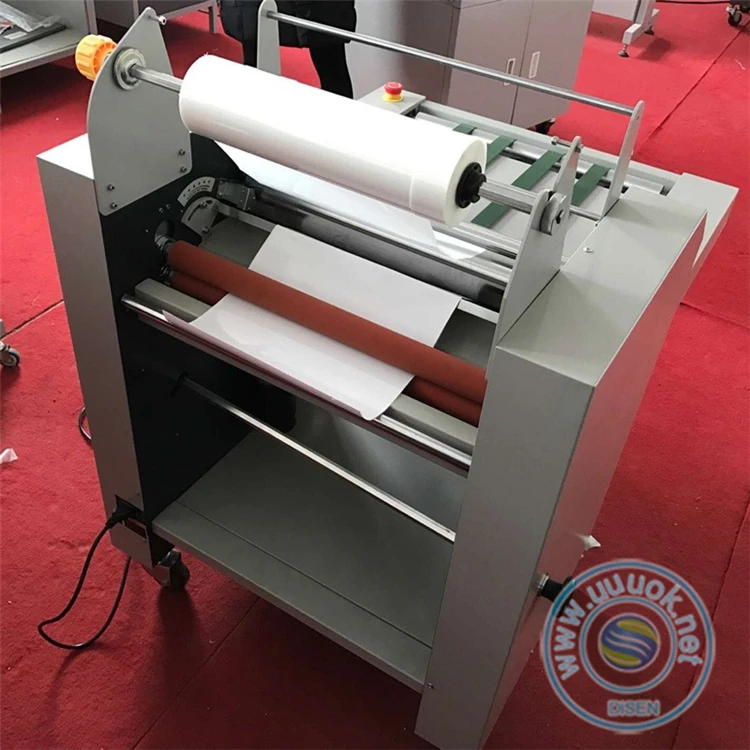

720 Semi-Automatic Electric Hot And Cold Laminating Machine

This machine covers a small area, is operated conveniently, run fast. It's equipped with automatic temperature-control and speed-regulation, automatic feeding. Several rolls or redundant rolls can be slit at one time, so this machine is regarded as a slitter.

The machine adopts pre-coated film as the material. It is widely used for lamination on the surface of window packing paper boxes, various books, maps, pictures, certificates, holographic cellphone etc. After the above products are laminated, they have the features of water-resistance, clear graphic arts and strong three-dimensional sense.

Model | 490 | 720 |

Max. lamination width | 490mm | 720mm |

Laminate Thickness | 60-800gsm | 60-800gsm |

Max. lamination speed | 9m/min | 9m/min |

Warming up time | 10min | 10min |

Suggested laminate bopp film | 25-250mic | 25-250mic |

Max. temperature | 150 degree | 150 degree |

Operating panel | LCD screen | LCD screen |

Auto feed paper with belt | Yes | Yes |

Single/Double Laminate | Yes | Yes |

Cold&Hot Laminate | Yes | Yes |

Cut film knife | Yes | Yes |

Perforating knife | Yes | Yes |

Auto rewinding paper | Yes | Yes |

Reverse | Yes | Yes |

Dia. of core | 1",1.5",3" | 1",1.5",3" |

The quantity of roller | 4pcs | 4pcs |

Speed control | 9 gear | 9 gear |

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

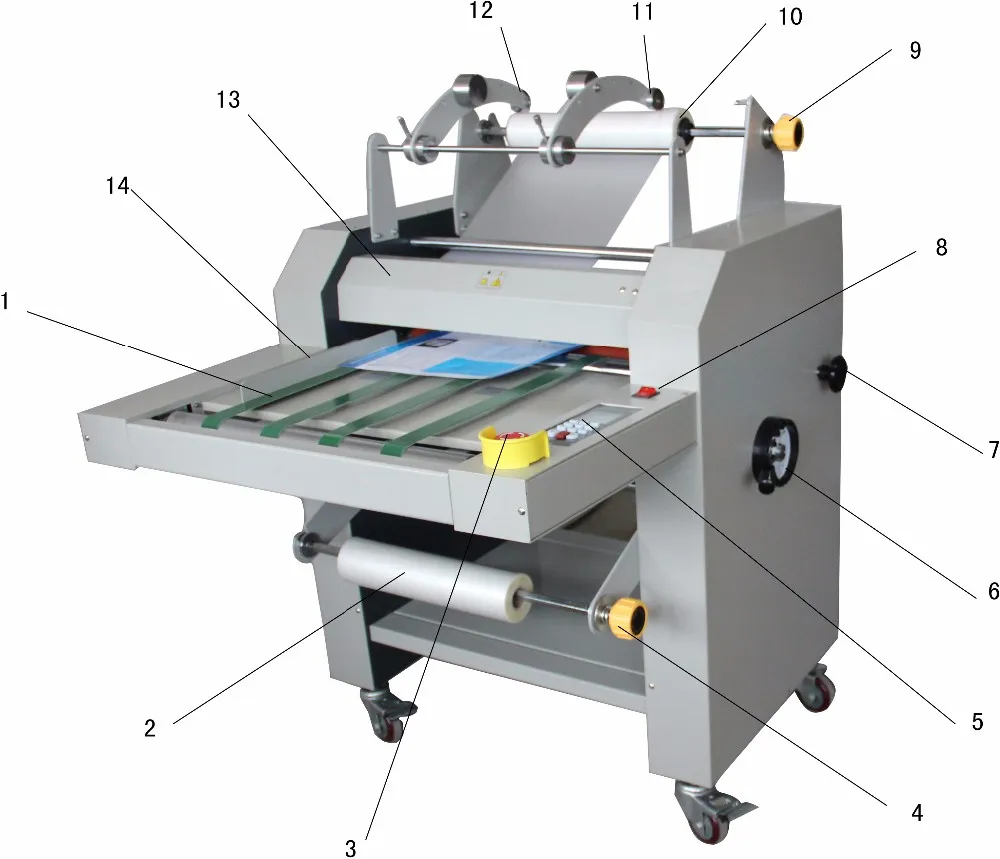

1. Conveyor belt | 8.Power switch |

2. Bottom film | 9. Adjust upper film adapter |

3.Emergency stop | 10.Upper film |

4.Adjust bottom film adapter | 11. Cut knife |

5. Operating panel | 12. Perforating knife |

6. Handle | 13. Safty cover |

7. Rull fim handle | 14. Limting block |

15.Heating upper steel roller | 17. Anti curling bar limiting |

16. Temperature sensor | 18. Anti curling bar |

19. Pull film roller |

TROUBLESHOOTING | ||

Machine will | a.Power switch is in “o” | a.Put the power switch to |

There is power, but the rollers are not turning after the “RUN” button is pressed | a.Safety cover is not closed. | a.Close the safety cover to active the safety switch. |

The unit is not heating up | a.The machine is in “COLD” mode. | a.Switch to “HOT” mode. |

The paper is not automatic feeding | a.The paper feeding roller is damaged. | a.Change the roller |

Many papers are feeding at the same time | a. Paper board is too low | a. Turn the paper board up. |

Curled lamination: | The main roller temperatures are too low and/or lamination speed is too fast. | Raise the roller temperatures and/or lower the lamination speed. |

Packaging | |

Size | 115cm(L) * 105cm(W) *111cm(D) |

Weight | 180Kgs |

Packaging Details | The normal package is non-fumigation casewooden box(Size: L*W*H). |