Машина для розлива воды под

- Категория: Packaging Machine >>>

- Поставщик: Zhangjiagang,Paima,Import,And,Export,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 13685.59 $* | 14369.40 $* |

| Aug-17-2025 | 13570.31 $* | 14249.33 $* |

| Jul-17-2025 | 11385.46 $* | 11954.25 $* |

| Jun-17-2025 | 13340.76 $* | 14007.69 $* |

| May-17-2025 | 11615.45 $* | 12196.24 $* |

| Apr-17-2025 | 13110.35 $* | 13766.71 $* |

| Mar-17-2025 | 12995.67 $* | 13645.25 $* |

| Feb-17-2025 | 12880.96 $* | 13524.31 $* |

| Jan-17-2025 | 12765.80 $* | 13403.5 $* |

Характеристики

Product Overview

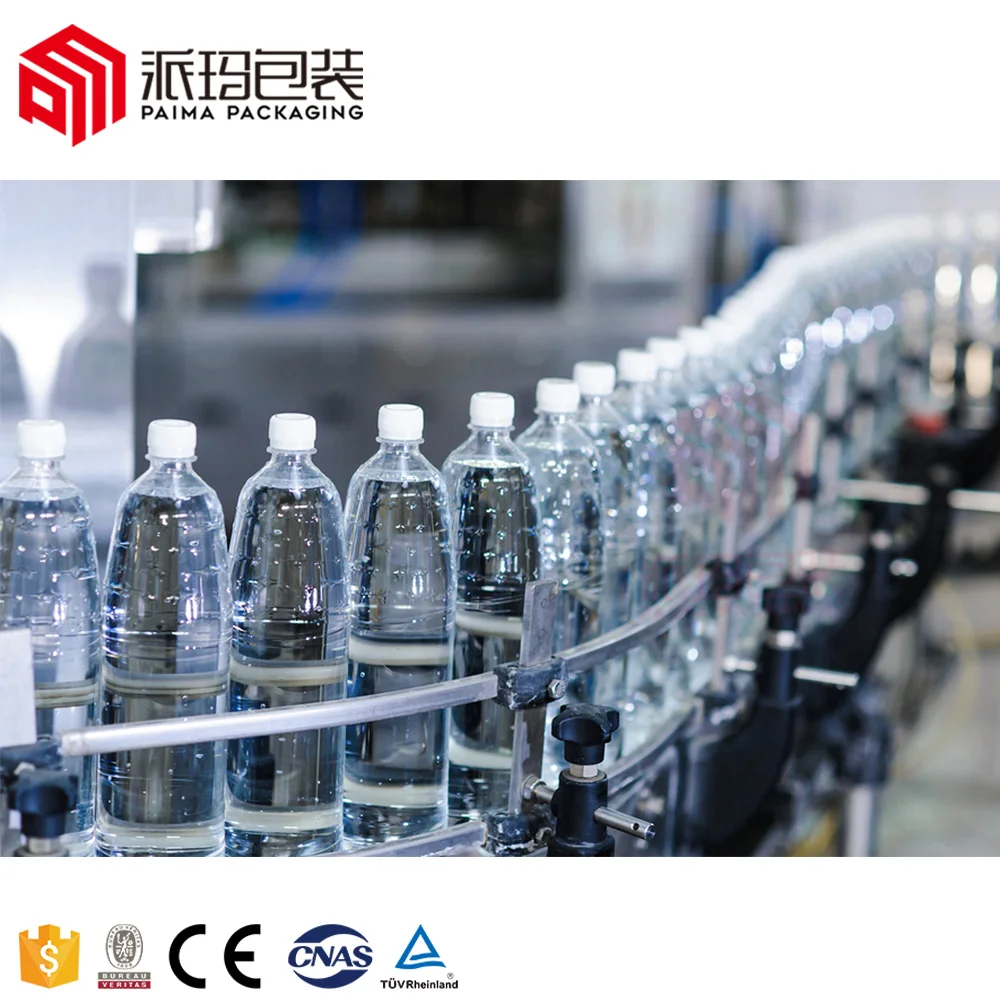

3 in 1 Automatic water bottling machine

CGF series Wash-filling-capping 3-in-1unit: Beverage Machinery is used to produce polyester bottled mineral water, purified water, alcoholic beverage machinery and other non-gas beverage machinery. Beverage Machinery can finish all the process such as washing bottle, filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

The Complete Bottled Mineral Water / Pure Water Production Line used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic.

PRODUCT SPECIFICATIONS

Plastic Bottle Minerial / Pure Water Filling Machine

Bottle Material: PET Bottle

Cap: PE

Bottle Volume: 100-2500ml

Production Speed: 1000-32000bph

Suitable Bottle:

Height 170-320

Diameter 20-100

Project | Water bottling machine | Data | |||||||||||

Model | CGF 8-8-3 | CGF 14-12-5 | CGF 18-18-6 | CGF 24-24-8 | CGF 32-32-10 | CGF 40-40-12 | CGF 50-50-16 | ||||||

Capacity | 2000 | 4000 | 8000 | 12000 | 14000 | 18000 | 20000 | ||||||

Bottle shapes | PET circular or square bottles | 125Ton | |||||||||||

Bottle height (mm) | 160-320 | 96kN | |||||||||||

Bottle diameter(mm) | Dia50-115mm | ||||||||||||

Compressor air pressure(Mpa) | 0.3-0.7Mpa | 60kN | |||||||||||

Washing meidum | Aseptic water | 6750ml | |||||||||||

Rinsing pressure(Mpa) | >0.06Mpa <0.2Mpa | 500N.m | |||||||||||

Application | Mineral/pure/drink water bottling production line | ||||||||||||

Total power (KW) | 4.4 | 4.4 | 4.4 | 5.2 | 6.2 | 7.8 | 8.6 | ||||||

Overall dimensions (L*W*H) | 2300*1900*2300 | 2500*1900*2500 | 2800*2150*2500 | 3100*2500*2500 | 3800*2800*2500 | 4500*3300*2600 | 4850*3800*2750 | ||||||

Weight(kg) | 2500 | 3200 | 4000 | 4500 | 6000 | 8000 | 9500 | ||||||

Devices | Brand | Origins |

PLC | SIEMENS | Germany |

Inverter | ||

Touch Screen | ||

Switch | ||

Contactor | ||

Relayer | ||

Solenoid Valve | AIRTAC | Taiwan, China |

Drive motor | FEITUO | Swiss |

Reducer | CNP | China |

Water Pump | SKF | China |

Main Bearing | AUTONICS | Sweden |

Sensor | AIRTAC | Korea |

Air component | ABB | Taiwan, China |

FEATURES AT A GLANCE

Technical Features:

1. It is adopted that direct connection between air conveyor and inlet starwheel instead of screw and conveyor chains, which is easier for bottle changing.

2. There is no need to adjust the height of equipment through neck holding tech for bottle transportation.And what is only to change some spare parts.

3. By 3-in-1 monoblock, the bottle goes through rinsing, filling and capping with little abrasion, and the transferring is stable, bottle changing is easier.

4. High speed filling line is of clamp transferring technology.Bottle shapes are more varied, and the working table inside the machine is more laconic.

5. Specially designed stainless steel bottle clamp dose not contact the thread parts of the bottle neck, avoiding the second contamination.

6. The bottle-out starwheel is of screwdown shape.When bottle size is changed, there is no need to adjust the transferring chain's height.

7. High speed and large flow filling valve assures the high filling speed and exact fluid level.

8. Parts contact with the liquid are all of excellent stainless steel or food level plastic.The electric system is of international brand and achieves the national food sanitary standard.

PRODUCT CONFIGURATION

WASHING PARTS

The rotary disk is fully made of SUS304 stainless steel.

Using imported special efficient spray nozzle, the washing water will be sprayed in a particular angle, can wash any part of the inner wall, rinse with water thoroughly and save flush bottle.

Bottle clamp and lifting mechanism of sliding sleeve adopts Germany Igus corrosion resistant bearing without maintenance. Washing part moves by a frame in the transmission system through the gear transmission.

FILLING PARTS

The filling part is manly composed of a filling valve and filling transmission parts. The washed bottle reaches the filling

position via the bottle shifting wheel. In the mean time, the bottle clamping plate of the filling machine will clamp the bottle and move up to seal the bottle, filling valve will open, send the liquid into the bottle. When the liquid level of the bottle reaches the trachea of the filling valve, the filling will stop.

CAPPING PARTS

The capping machine is the highest precision in 3-in-1 unit machine, on the reliability of equipment operation, has enormous influence on the defective rate of the product.Introduced the world's most advanced Italian AROL capping machine technology, combining with the filling machine production experience improvement, and ask college of Shanghai Jiao Tong university mechanical engineering institute of electrical and mechanical design and automation technology of experts and professors to help design.

Full line of products

Complete bottled water production line

1. Bottle blowing system to make PET plastic bottles ( Semi automatic / Fully automatic )

2. Water treatment system purify water (Sand filter,carbon filter,RO/UF ,Ozone sterilizer,UV sterilizer and etc.)

3. Air conveyor for empty bottle loading

4. 3 in 1 monoblock Rinser-filler-capper machine

5. Labeling machine(PVC sleelve labeling machine/OPP hot melt glue labeling machine/Self-adheisive labeling machine )

6. Cap loader load caps

7. Code printer (Ink-jet printer/ laser-jet printer)

8. End packaging ( PE film shrink wrapping machine / Carton packing machine )

Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Water treatment system includes silica sand filter, active carbon filter, sodium ion exchanger, Ozone generator and UV Sterilizer, RO machine (If mineral water, use hollow fiber filter). All these machines made by stainless steel food stage.

Shrink labeling machine

This Shrink Sleeve Labeling Machine adopts international advanced technology, cover the circle label on the PET bottle, and then hot shrinking to fix on the position which bottle body designated. It adopts combination designing of modularization, and makes the machine reasonable.

Shrink wrapping machine

PE film Shrink wrapping machine is suitable for wrapping of such prkducts as mineral water, bottles beer, drinks etc without bottom-tyay (or with bottom-tray). Working with PE shrink tunnel to pack the goods perfectly. The whole producing process adopt the Germany aduanced technics.

Successful Project

Water Project in Ethiopia

Water Project in Yemen

Water Project in Georgia

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.