BG-150 покрытие лакировочная машина Планшета Автоматическая нержавеющая сталь фармацевтическая машина/таблетка/планшет

- Категория: Film Coating Machines >>>

- Поставщик: Shanghai,Aligned,Machinery,Manufacture,&,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 43792.58 $* | 45982.17 $* |

| Aug-15-2025 | 43424.14 $* | 45595.55 $* |

| Jul-15-2025 | 36432.41 $* | 38254.7 $* |

| Jun-15-2025 | 42688.40 $* | 44822.17 $* |

| May-15-2025 | 37168.6 $* | 39026.95 $* |

| Apr-15-2025 | 41952.49 $* | 44050.17 $* |

| Mar-15-2025 | 41584.65 $* | 43663.41 $* |

| Feb-15-2025 | 41216.93 $* | 43277.19 $* |

| Jan-15-2025 | 40848.69 $* | 42890.92 $* |

Характеристики

Coating Machine

Application

Used for coating various tablets, pills and bubble candies as well as chewing gum with organic film, water-soluble film and sugar film, etc. And it has such characteristics as high efficiency, low energy consumption and small floor area, etc. And it can be widely used for coating various tablets, pills and sweets with organic film, water-soluble film and sugar film etc in such fields as of pharmaceutical, food and biological line.

Basic Working Principle: The tablets make complicated and constant track movement with easy and smooth turning and frequent exchanging in the clean and closed rotational cylinder of the film coating machine. And it can automatically spray coating medium according to the process flow and reasonable process parameters. The hot air exhausted through the bottom of the tablets under the effect of air exhaust and negative pressure so as to make coating medium dry quickly on the surfaces of the tablets and form a firm, fine and close and smooth surface film.

Main Machine

During run of film coating in the main machine, it shows such features as free dust fly-off, syrup splash, operation condition improvement, little cross contamination to tablets, simple coating process, shortening coating time as well as high production efficiency etc.

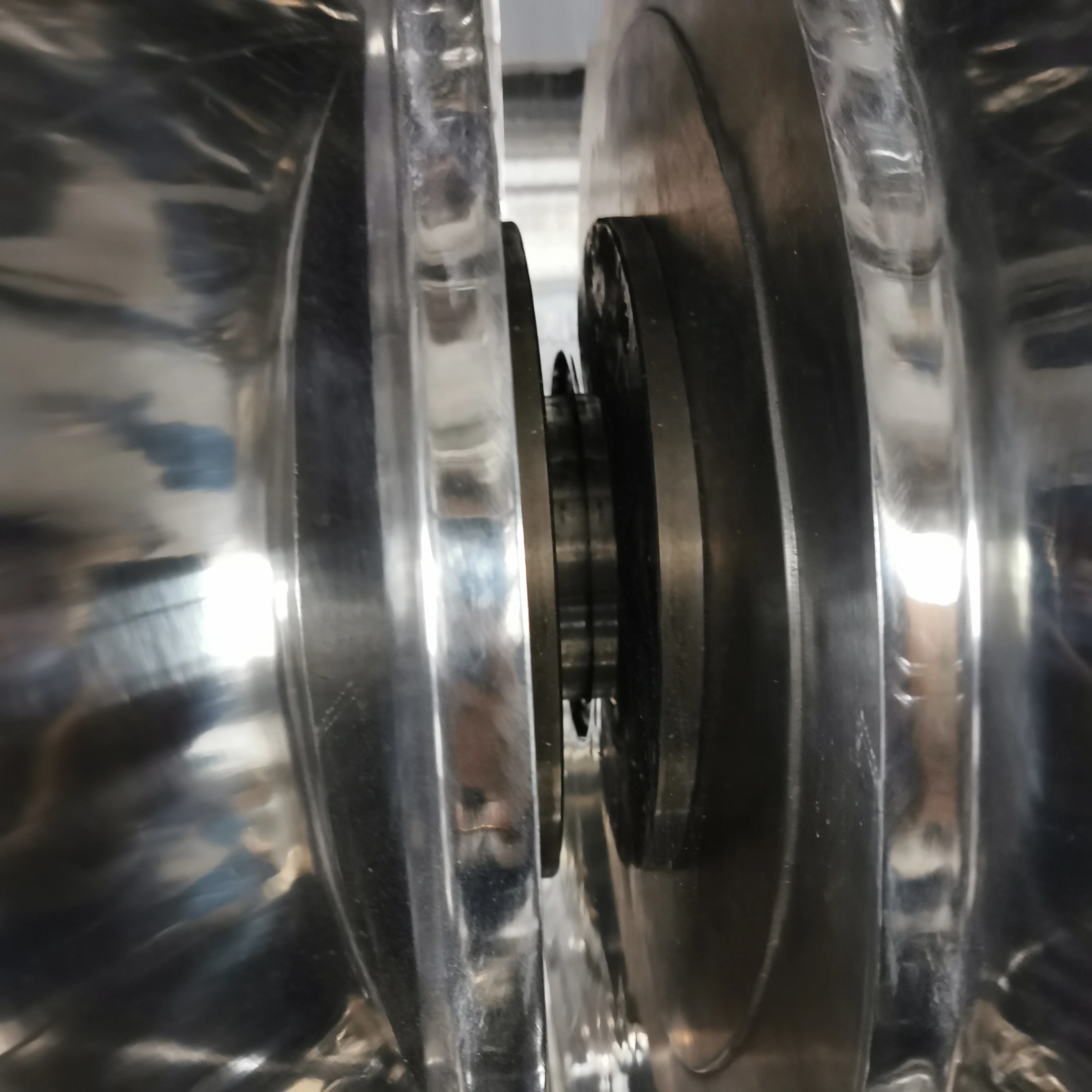

Adopts a new-type micro-computer PLC, by which temperature and negative pressure control system are displayed on the touch screen, with such characteristics as programmability, automatic adjustment of negative pressure and air flow, automation of process parameters, making accurate production of various batches of products with the same technical parameter. It make lead at home in data storage and printing system, by which process parameter and process flow of each batch of production can be accurately recorded with a printer as requested from users. The explosion-proof motor drives the drum to rotate in the clockwise direction through the cycloidal pinwheel, It's attached with a cleaning system and equipped with outlet adjustment apparatus, with which a few medicines can be coated.

Hot air cabinet

At first, air inhaled in through the centrifugal fan should be purified up to the 100,000 Level after three times filtration, involving primary filtration, medium filtration and high filtration, then be blown to the drum of main machine through the (steam or electro-thermal) heat exchanger. Equipped with a vibration damper, it is in normal run with noise lower than 70 dB.

Air Exhaust Cabinet

Used for pumping air out of drum (including dust absorption), keeping the working area under negative pressure, dust abatement and filtration. Equipped with a vibration damper, it is in normal run with noise lower than 70 dB.

Air Spraying System

High-pressure uniform vaporized liquid can be sprayed through the crawler pump and the air spray gun imported from Japan.

Thermostatic mixing drum

The mediums can be electrically heated and stirred into a uniform liquid at a preset temperature

Performance and Characteristics

1. With PLC module, all operations such as hot air temperature setting and control, revolutions of the drum adjustment, automatic control and display of negative pressure etc can be in run by pushing the touch key on the computer-controlled panel fully sealed with slight touch film interface.

2. The machine is free to clean, with such characteristics as reliable and stable performance. The streamline guiding-type mixer drives tablets to make easy and smooth rotation without fragment and chipped edge, which improves the yield. The guiding sheet has a narrow surface, to which no dressing can be stuck, economization on dressing and improving the quality of finished products.

3. The constant-pressure variable crawler pump features the revolution radius of the roller subject to pressure, automatic control of output syrup amounts and sprayed syrup amounts, stabilization of atomization, simplify of spraying system, economization on dressing, easy to fully clean.

4. The specially designed imported pray gun features ease in operation and control technological requirements, uniform density and particle size, uniform atomization and large spray area, practical to adjust flow, free leakage and blockage, angle and sector. The gun can be in operation until its head keeps in the range of 0.29Mpa to 0.39Mpa. Until now, it has been favorably reviewed from users at home and abroad.

Technical Parameters

Item | BG-150E | |||

Load capacity | 150 kg/t | |||

Diameter of coating drum | Φ1200 mm | |||

Diameter of feeder | Φ475mm | |||

Rotary speed of drum (R/min) | 1-16 r.p.m | |||

Power of Main machine | 2.2 kw | |||

Power of air exhaust cabinet motor | 5.5 kw | |||

Flux of air exhaust | 7419 m3/h | |||

Power of hot air cabinet motor | 1.5 kw | |||

Flux of hot air | 2356 m3/h | |||

Hot air adjustment scope | ~80℃ | |||

Level of hot air purified | 100,000 class | |||

Power of peristaltic pump motor | 0.55kw | |||

Wall thickness of silicone tube | Φ1.6-2.2mm | |||

Volume of main machine (L×W×H) | 1570×1260×2030mm | |||

Weight of main machine | 850kg | |||

Overall dimension of hot air cabinet | 900×800×1935mm | |||

Weight of hot air cabinet | 450kg | |||

Overall dimension of air exhaust cabinet | 950×950×1950mm | |||

Weight of air exhaust cabinet | 550kg | |||

External condition | Purified air | Pressure | ≥0.4MPa | |

Air consumption | 1m3/min | |||

Water sources | Pressure | ≥0.15MPa | ||

Tube radii | 1 1/2″ | |||

Steam heating up style | Steam | Pressure | ≥0.4MPa | |

Gas consumption | 100kg/h | |||

Power sources | Three-phase five-line 10kw | |||

Electricity heating up style | Power sources | Three-phase five-line 38kw | ||