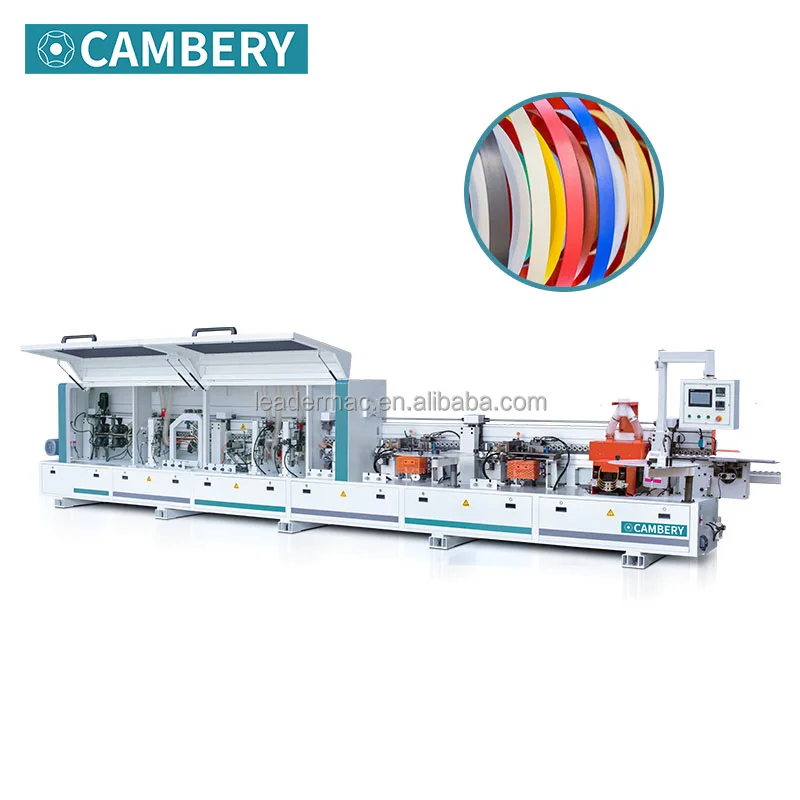

Высококачественный Кромкооблицовочный станок эффективный деревообрабатывающий ABS ПВХ

- Категория: Техника для производства древесных плит >>>

- Поставщик: Foshan,Leader,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 31833.56 $* | 33425.78 $* |

| Aug-15-2025 | 31565.35 $* | 33143.11 $* |

| Jul-15-2025 | 26483.50 $* | 27807.71 $* |

| Jun-15-2025 | 31030.63 $* | 32582.61 $* |

| May-15-2025 | 27018.78 $* | 28369.22 $* |

| Apr-15-2025 | 30495.41 $* | 32020.46 $* |

| Mar-15-2025 | 30228.76 $* | 31739.32 $* |

| Feb-15-2025 | 29960.88 $* | 31458.19 $* |

| Jan-15-2025 | 29693.60 $* | 31178.83 $* |

Характеристики

PRODUCT INFORMATION

TECHNICAL CHARACTERISTICS

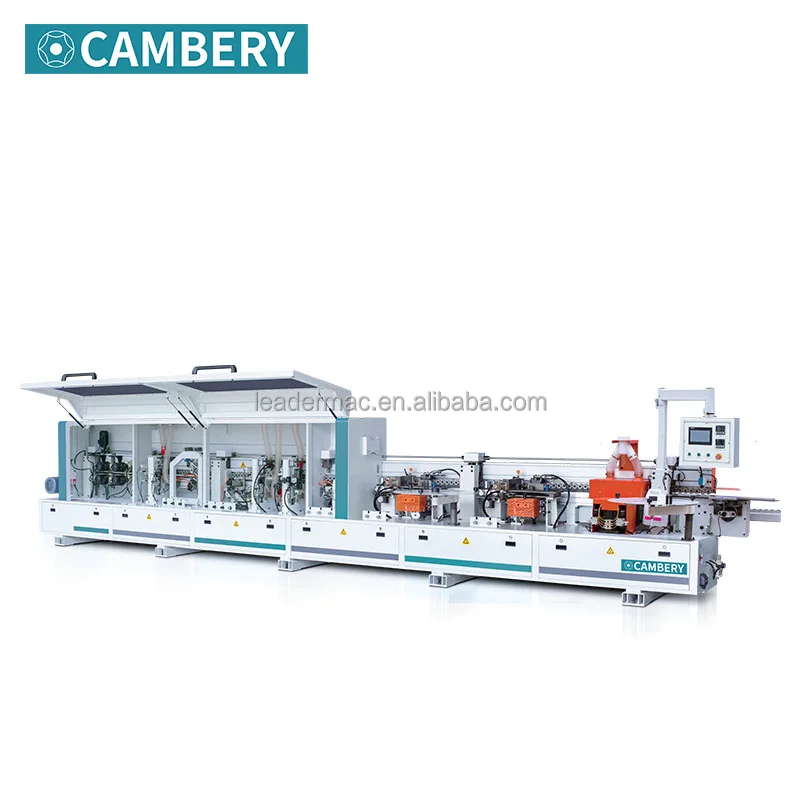

Overall Size | Approx. 8300mm*760mm*1600 mm |

Weight | Approx. 3300 kg |

Power Supply | 380V 50Hz or customized |

Total Power | 20.0kW |

Pneumatic Loaded | 7 bar |

Feeding Speed | Up to 23 m/min |

Panel Application Spec. | Min. Working Size: From 60mm*60mm; Max. Working Size: Up to 1220mm*2440mm; Thick: 10-60mm |

Edge Tape Application Spec. | Thick: 0.4-3mm Width: 12-65mm |

Control System | Detla® PLC with 10in. full color touch screen. |

Electronic Components | Schneider® or equivalent |

Pneumatic Components | AirTac® or equivalent |

DETAILS DISPLAY

STABLE BEDFRAME

● Stable bedframe which is manufactured by a rigid foundation, with superior welding, CNC machining, tempering and painting process.

ELECTRONIC SYSTEM

● Delta® programmable logic controller.

● 10in. Full color touch screen control panel, user-friendly interface in English.

● 10in. Full color touch screen control panel, user-friendly interface in English.

QUALITY COMPONENTS

● Schneider® electronic components.

● AirTac® Pneumatic components.

● High quality and durable silicon feeding belts.

● Electric-drive feeding height adjustment design, with visualized height meter, ease and precise.

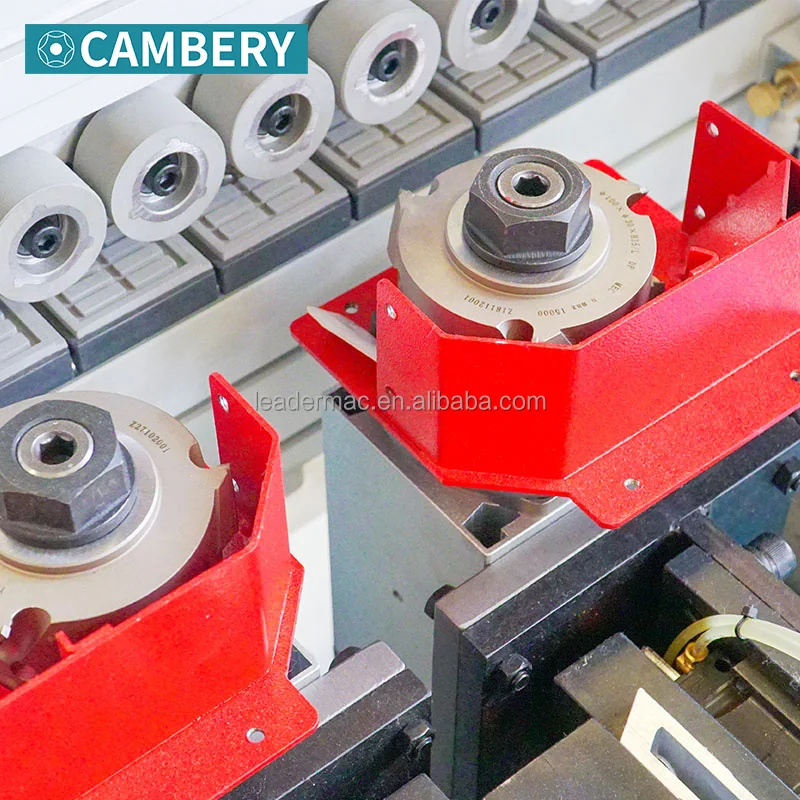

● Pre-milling element, for straightening the edge with conspicuous protection and dust removal cover.

● Non-stick coated heating tank with conspicuous protection cover, easy to clean.

● Quadruple chromized pressing roller, with independent pneumatic forcing cylinder.

● Dual glue melting elements, gluing station and pressing station, fast exchange glue application.

● Dual rail automatically double head cutting elements, fast, precise and consistent.

● Rough trimming and Pneumatic fine trimming elements.

● Dual corner trimming elements, for rounding panels’ corners by separated.

● Dual scraping elements, for removing the extra tape.

● Cleaning solution spray, for removing the exceeded glue.

● Dual buffing elements, for burnishing the edges with double sides treatment.

OPTIONS

● Safety cover for pre-milling element.

● Fast EVA melting system.

● PUR melting system.

● Multi belts exchange system. (2/4/6)

● Pre-heating system for panels or belts.

● PC monitoring

● Self-cycle transportation system.

● Multi belts exchange system. (2/4/6)

● Pre-heating system for panels or belts.

● PC monitoring

● Self-cycle transportation system.

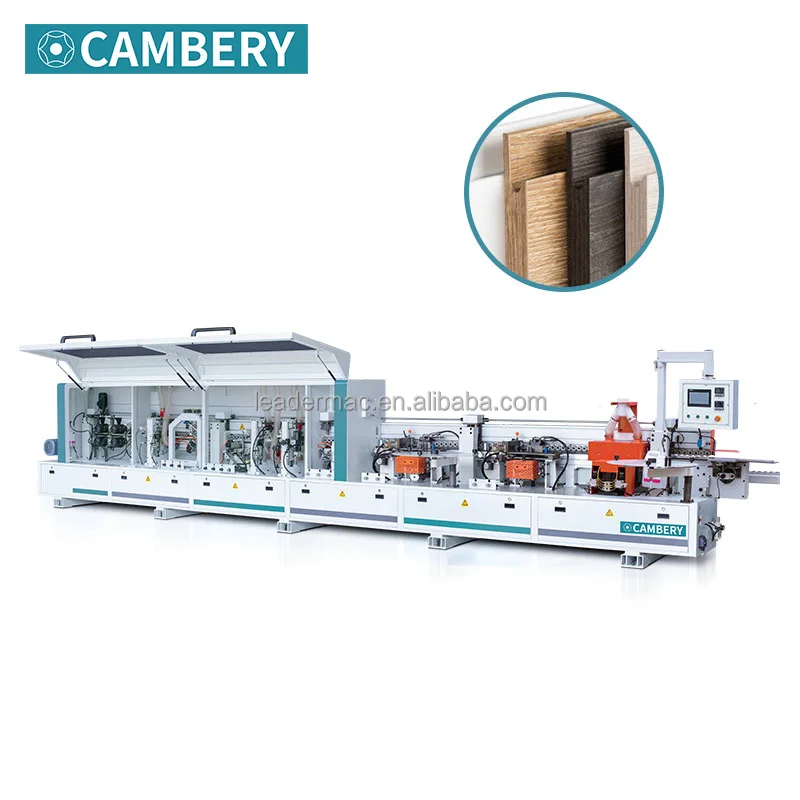

APPLICATION

Ideal system with ease and precision for panel edge banding, MDF, particle board, OSB, solid wood, and aluminum honeycomb etc.

HOT SALE

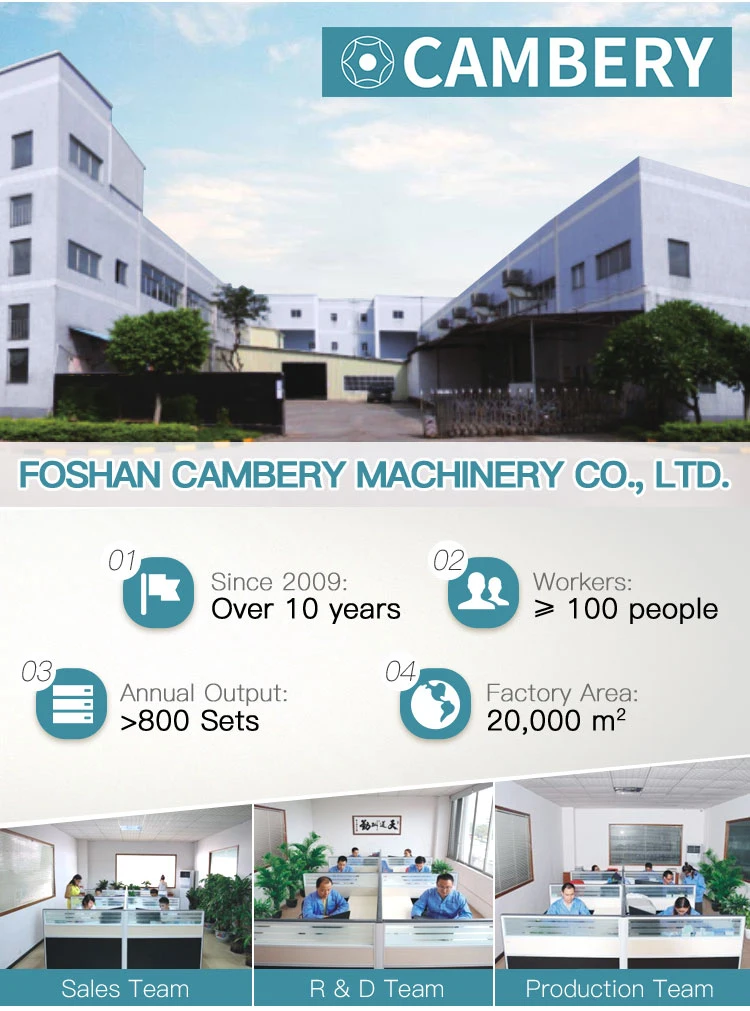

COMPANY OVERVIEW

WELCOME TO VISIT US

Cooperation with up to 50 countries around the world.

Cooperation with up to 50 countries around the world.

OUR CERTIFICATION

FAQ

Q1. Warranty

A1. 12 months warranty is effective from the date of acceptance of the machine.

Q2. Payment Terms

A2. TT 30% down payment, 70% before shipment.

Q3. Delivery Time

A3. 15-30 working days from the receipt of the down payment.

Q4. Machine installation

A4. Cambery could assign the technician to the place for the on-site installation if requested by the purchaser.

Q5. Technical Support

A5. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the

troubleshooting is provided within 48 hours.

Q6. Demo and Testing

A6. Cambery built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.

A1. 12 months warranty is effective from the date of acceptance of the machine.

Q2. Payment Terms

A2. TT 30% down payment, 70% before shipment.

Q3. Delivery Time

A3. 15-30 working days from the receipt of the down payment.

Q4. Machine installation

A4. Cambery could assign the technician to the place for the on-site installation if requested by the purchaser.

Q5. Technical Support

A5. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the

troubleshooting is provided within 48 hours.

Q6. Demo and Testing

A6. Cambery built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.