Производственная линия для непрерывного литья вверх на площадке онлайн-продаж в

- Категория: Metal Casting Machinery >>>

- Поставщик: Wuxi,Jintong,Furnace,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.62 $* | 0.37 $* |

| Aug-19-2025 | 0.92 $* | 0.38 $* |

| Jul-19-2025 | 0.87 $* | 0.26 $* |

| Jun-19-2025 | 0.60 $* | 0.4 $* |

| May-19-2025 | 0.34 $* | 0.74 $* |

| Apr-19-2025 | 0.35 $* | 0.16 $* |

| Mar-19-2025 | 0.26 $* | 0.37 $* |

| Feb-19-2025 | 0.61 $* | 0.99 $* |

| Jan-19-2025 | 0.64 $* | 0.70 $* |

Характеристики

1.Brief introduction

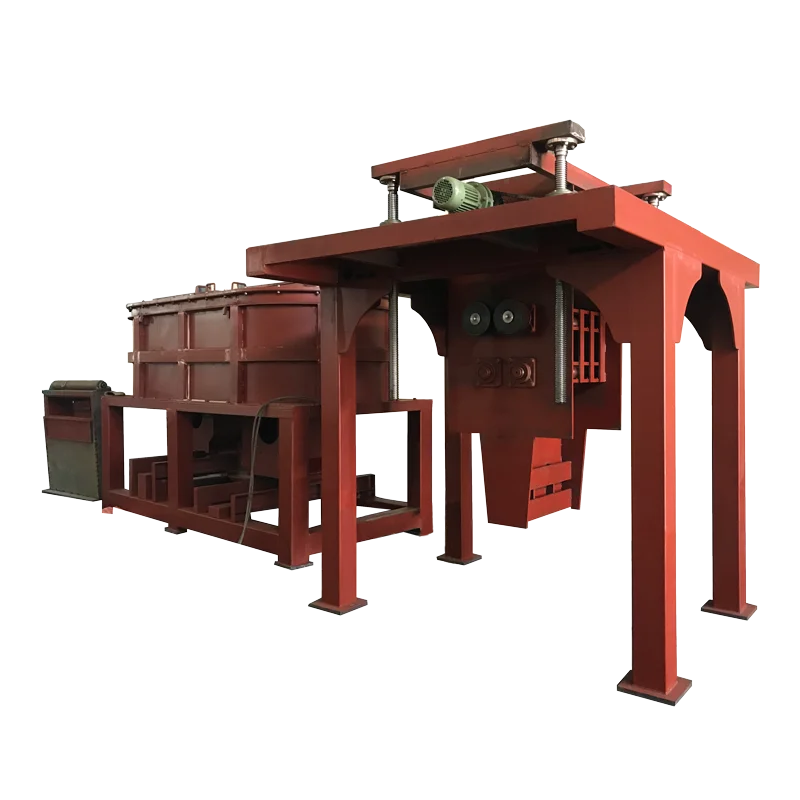

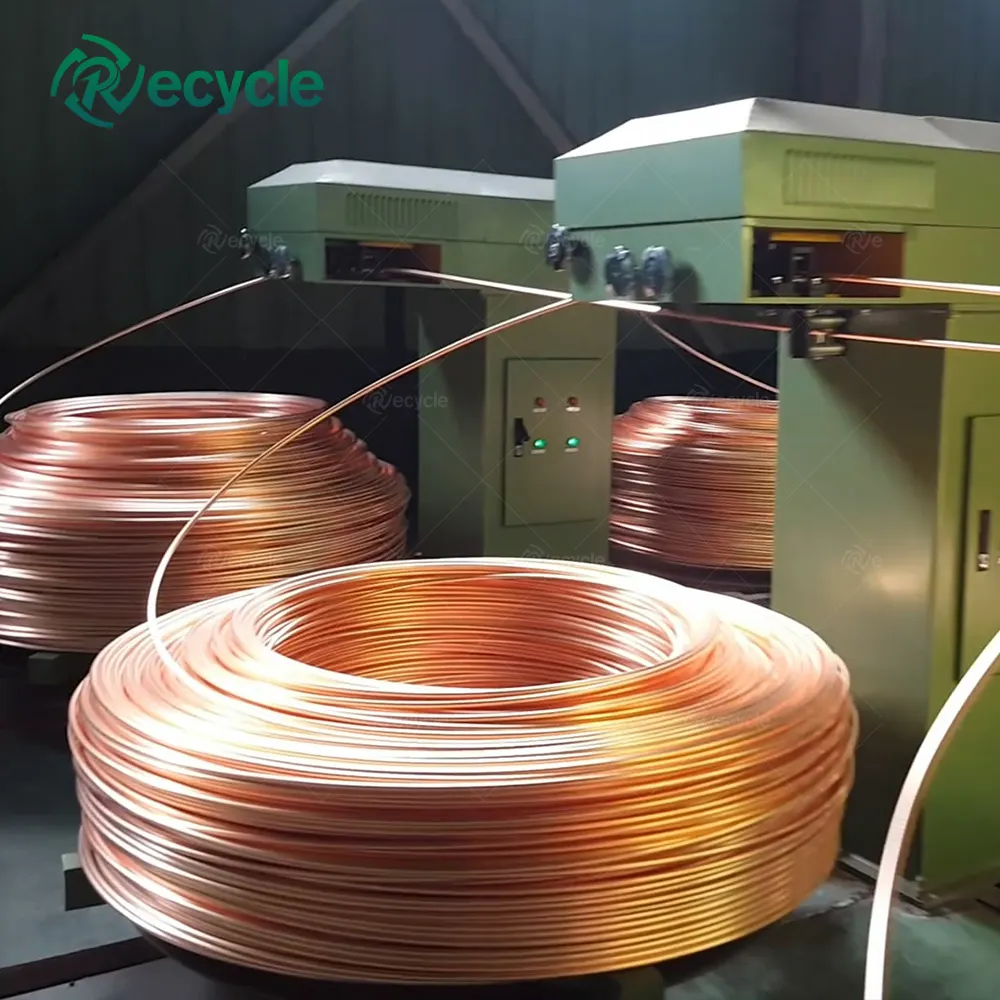

The mainly machine includes power frequency induction furnace, upward continuous casting machine, guide wheel frame, tension frame, take-up machine, cooling water system, electric system, feeding system and measure temperature system and so on.

The upward continuous casting production line is used to produce the long and bright oxygen-free copper rod and copper tube. The mainly process is that, put the copper cathode into the melting furnace straightly. It will be melted into liquid by frequency inductor .And the liquid of copper will flood into the holding furnace automatically and smoothly through the transition house, and then it will be deoxidized by the charcoal or graphite flake covered. The holding furnace keeps the copper liquid temperature in 1150℃±10℃.The upward continuous casting machine crystallizes the copper liquid in crystallizer quickly, then continuously produces copper rod, then the final product will be finished through the guide wheel frame and the tension frame to the take up machine and other accessory equipment.

Craftwork Flow

1. Furnace

Parameter:

No. | Parameters: |

1 | Rated Power: melting furnace 80kw, holding furnace 45kw working power |

2 | Type: Melting Copper Scrap/Temperature Holding |

3 | Model: GYT300/200 |

4 | Input voltage: 380 VAC |

5 | Content Capacity: 5000KG |

6 | Input phase: 3 phase (ABC) |

7 | Power Factor: 0.95 |

8 | Input Frequency: 50 Hz |

9 | Melting Rate: 300KG/Hour |

10 | Working Temperature: 1200 ℃ |

11 | Hook: 2 |

12 | Cooling System: Water cooling |

13 | Voltage Regulating: Autotransformer |

14 | Temperature Measurement: Thermocouple |

15 | Electric Cabinet: 2 Sets |

2. Upward continuous casting machine

No. | Parameters: |

1 | Motor: Servo Motor 3KW (Single Servo Motor) |

2 | Up Drawing Speed: 0-1800mm/minute |

3 | Copper Rod Diameter: 8mm |

4 | Copper Rod Qty: 2pcs (will make 4 clamps, 2 extra for future expansion) |

5 | Control: PC Controlled |

3. Take-up Machine

No. | Parameters: | Qty |

1 | Motor: Variable Frequency Motor 3kw (Two side ) |

1 set

|

2 | Speed Reducer: Gear Reducer | |

3 | Take-up Reel Capacity:2-3T | |

4 | Take-up coil standard for rod: 800mm × 1500mm× 800mm | |

5 | Take-up form: Automatic adjust | |

6 | Take-up copper rod rang rod automatically |

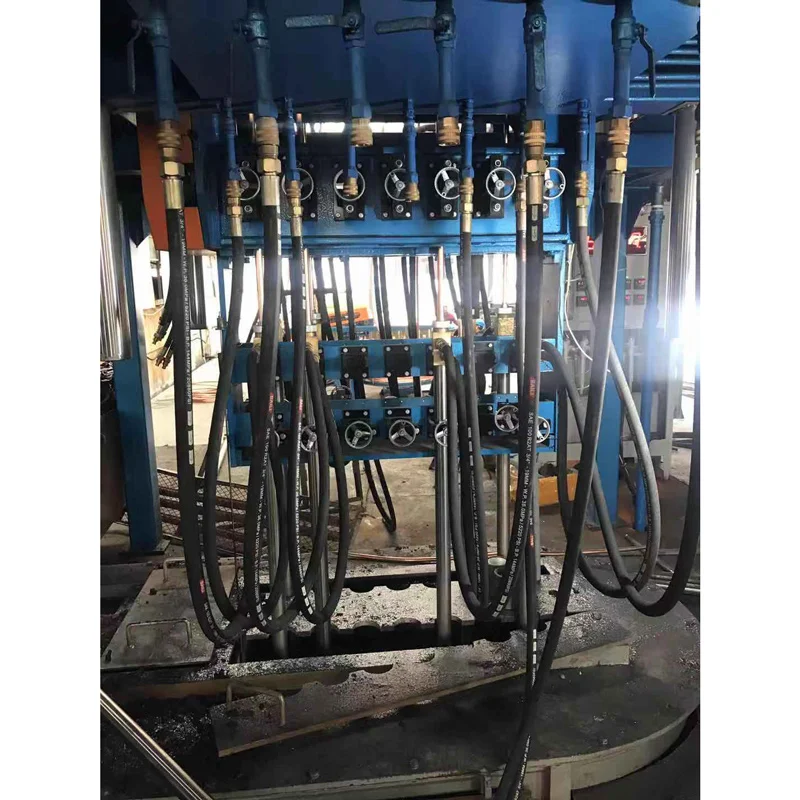

4. Crystallizer

No. | Parameters: | Qty | Remarks |

1 | Copper rod crystallizer outer tube | 2 pcs

| Outer tube: Steel Inner tube: Copper Length: 1370mm |

Copper rod crystallizer inner tube | |||

Quick connector | |||

High-pressure pipe 1800mm |

Part One: Supply Scope of full set | |||

No | Description | Qty | Specification |

1 | Melting and temperature holding furnace with Electrical cabinet | 1set | 80kw,45kw, water cooling |

2 | Upward continuous casting machine with single servo motor | 1set | 4strands, 3kw |

3 | Take-up machine | 1set | For 8mm copper rod |

4 | Tension frame | 1set |

|

6 | Wire separate frame | 1set |

|

6 | Cooling water monitoring tank | 1set | |

7 | Crystallizer outer tube | 2pcs | |

8 | Crystallizer inner tube | 2pcs | For 8mm copper rod |

9 | Quick connector | 4pcs | For 8mm copper rod |

10 | High-pressure pipe | 4pcs | 1800mm |

11 | Thermocouple | 1pc |

|

12 | Thermocouple sleeve | 1pc | silicon carbide |

13 | Floater | 2pcs |

|

14 | Graphite mold 8mm | 4pcs | 8mm |

15 | Graphite mold sleeve | 4pcs | 8mm |

16 | Drawing rod | 1pc |

|

17 | Voltage stabilizer | 1pc |

|

18 | Cathode feeding machine | 1pc |

|

Part Two : Furnace and other configurations | |||

No | Description | Qty | Specification |

1 | Furnace electrics | 1set | CHINT |

2 | AC servo system | 1set | Yaskawa AC servo motor and Mitsubishi PLC, Schneider low-voltage electrical appliance. |

3 | Low-voltage apparatus | 1set | Schneider |

4 | Driver/Invertor | 1set | Yaskawa |

5 | Touch Screen | 1set | WEINVIEW or KINCO |

6 | Circuit breaker of upcasting control board | 1set | Schneider |

7 | Contactor & Switch of upcasting control board | 1set | Schneider |

8 | Traction reducer | 1set | Zhengfei |

9 | Frequency Converter | 1set | Zhengfei |

Part Three: Prepare by customer own | |||

No | Description | Qty | Specification |

1 | Large platform | 1pcs | Including four pillars connected to the medium platform(20# steel channel, supplier provide drawings) |

2 | Equipment foundation | 1set | Fixed furnace body and medium platform(supplier provide drawings) |

3 | Electrical wire | 1set | Used for connection between machines |

4 | Wire bridge | 1set | Use the appropriate size when installing |

5 | Water supply system | 1set | Water supply pipeline (to equipment supply pipe), backwater pipeline (to equipment return tank and backwater tank), emergency water tower, emergency water source. |

6 | Generator set | 1pcs | As the backup power |

7 | Power supply system | 1set | 3 phase 380V |

8 | Electric travelling crane | 1set | 5T |

9 | Raw material | 10T | |

10 | Charcoal | 5T | |

11 | Graphite flake | 2T | |

12 | Workshop | Arrange according to the actual situation | |

13 | All equipment and tool related to installation and trial production | 1set | Just like: Welding machine, gas cutting, air pick, forklift and other lifting equipment and other tools |

Part Four: Tools preparation in advance

| |||

1 | Air compressor | 7.5kw | |

2 | Voltage stabilizer | 1set | 10kw |

3 | Pneumatic pick | 1pcs |

|

4 | High-pressure pipe | 1pcs | 18m ¾ inch (DN20mm ) |

5 | Cooling water pipe | 1pcs | 60m ¾ inch (DN20mm) |

6 | Electric wire |

| buy on site when engineer come |

7 | Diesel generator if needed min.150kw is cast of power cut off, if use for production, 200kw suggested | 1pc | |

Q. What is your MOQ?

A. 1 set.

Q. Your company is a trading firm? or Factory?

A. We are a factory with 10+ years experience in industrial melting feild. We currently have three branches: main frequency furnace production, medium frequency furnace production, component machine production. You are warmly welcomed to visit our factories.

Q. How is your products quality?

A. As a manufacturer, we have our own R&D team. Basing on several years of technical innovation, we have accumulated successful experience in induction heating, temperature holding, fast melting. We've customized so many furnaces with all positive feedbacks.

Q. What kind of material our furnace can melting?

A. Jintong is able to supply a melting production line such as copper/zinc/aluminum melting line.Jintong medium frequency furnace can also melt iron, steel, gold, silver and so on.

Q. I am not so familiar with your machine now. I am not sure I can use it well if I buy it from you.

A. Don't worry about this. With the machine, we will send you a brochure with detailed information of our machine operation. In addition, we will send you videos of machine set up and using. Our engineers are always available for consultation. Engineers can support at your place if it is needed.