Пластиковый процесс литья под давлением пластиковый продукт изготовленный на заказ литье

- Категория: Moulds >>>

- Поставщик: Foshan,Mogel,Hardware,And,Plastic,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.15 $* | 0.49 $* |

| Aug-16-2025 | 0.37 $* | 0.38 $* |

| Jul-16-2025 | 0.23 $* | 0.23 $* |

| Jun-16-2025 | 0.20 $* | 0.10 $* |

| May-16-2025 | 0.64 $* | 0.18 $* |

| Apr-16-2025 | 0.80 $* | 0.95 $* |

| Mar-16-2025 | 0.44 $* | 0.52 $* |

| Feb-16-2025 | 0.49 $* | 0.44 $* |

| Jan-16-2025 | 0.62 $* | 0.11 $* |

Характеристики

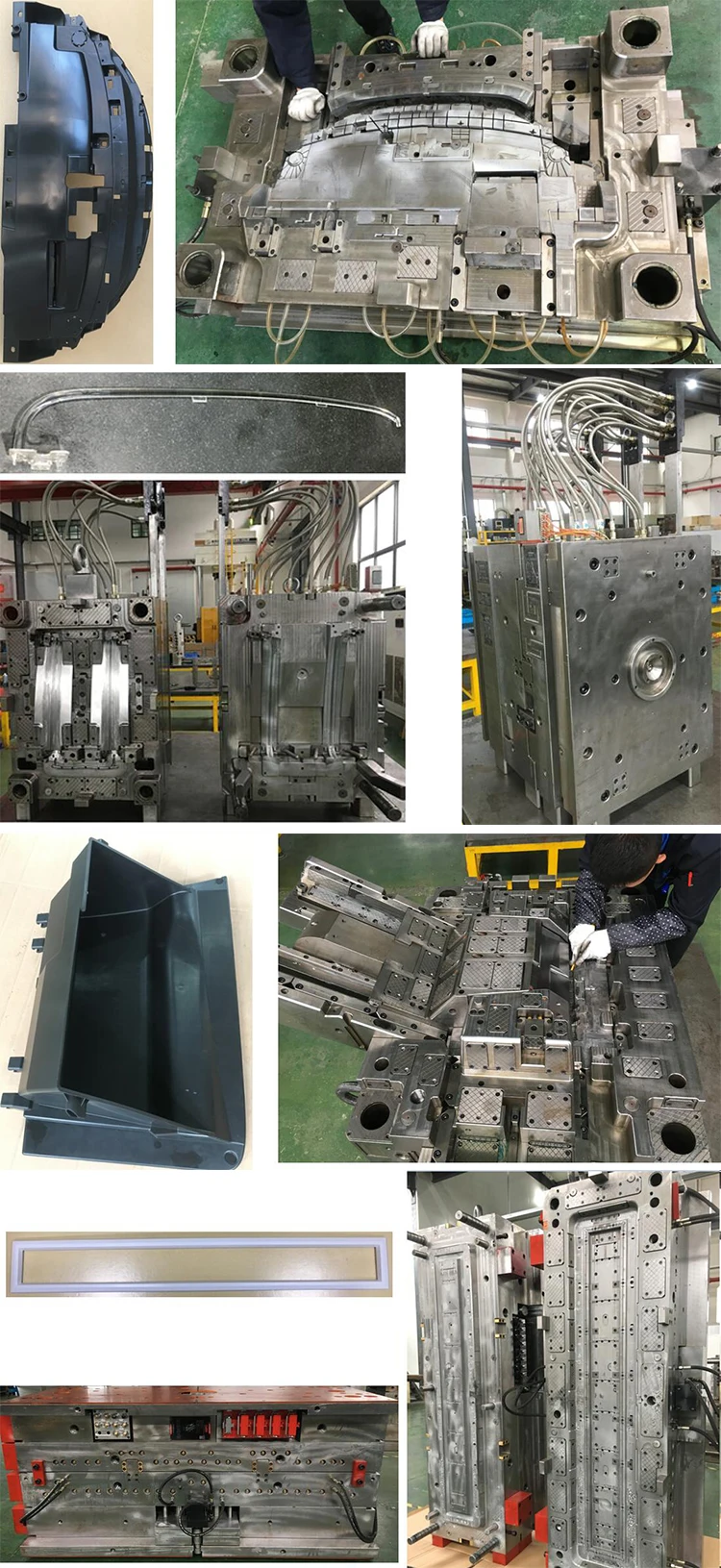

plastic injection molding process plastic product custom pp injection moulding

| Description of product |

| Product range | Mold design, mold making and produce plastic parts |

| Processing Craft | Mold fabrication, Injection etc; |

| Material | ABS,BMC, SMC, AS,PP,PPS,PC,PE,POM,PMMA,PS,HDPE,TPE,TPU etc |

| Surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc |

| Color | RAL/PANTONE color |

| Size | according to the drawing |

| Mold Standard | DME,LKM,FUTA,HASCO etc. |

| Advantages | Competitive price & Fast Delivery & Good quality |

| Mould Base | as per customer's requirement |

| Delivery time | 10-15 days after placed order |

| Tolerance | 0.01~0.1mm; |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

| Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

| Inspection | IQC, IPQC,FQC,QA |

| Application | All kinds of plastic injection parts being used in a variety of industrial application. |

| Service | Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

| Product details |

Design:

We have professional engineers design team,and can use CAD,Pro-E,UG,Solidworks etc.

Before the project started:

1, If you have 3D STEP/IGES/X_T drawing or 2D drawing, please directly send to us before quotation, then we will do DFM and mould design for you.

2, If you have samples no drawings, please directly provide us samples, we can design 3D for you,and quotation.

We offers comprehensive custom plastic injection molding services to a wide range of industries. From low volume work to high volume production runs, we have the expertise and facilities to meet our customers’ contract manufacturing needs. We offer two shot, sandwich and insert injection molding as well as micro and gas assist molding. We have both 10K and 100K clean room manufacturing facilities for those customers in the medical, pharmaceutical, food, beverage and electronics industries. Our comprehensive plastic injection molding abilities include machines with clamping forces from 18 to 3,000 tons, allowing us to produce nearly any plastic part including micro parts, thin-walled parts, and large components that require multiple shots.

We can source and mold any grade of material from typical commodity grade plastics, to engineering, functional, and structural grade materials in a variety of colors and formulations. In addition to injection molding, we offer many secondary services including sonic vibration, RF welding, hot stamping, etching, printing, plating, and packaging. Our manufacturing processes are highly automated, which allows us to run a precise and efficient production floor with minimal overhead costs. These capabilities allow us to provide fast and cost competitive manufacturing services to our customers without sacrificing precision and quality.

We have our own mould making production line, it’s better for us to control the quality, and improve our effective to shorten the production time. Our mould life usually can meet 1,000,000 shots.pl

Large mold production:

| Our Service |

1. Product design and development, both ODM and OEM.

2. Scanning data. (Get 3D drawing per your delivered sample)

3. Drawing re-construction. (Simple design is free of charge)

4. Prototype making. (It is optional and we will charge the cost.)

5. Tooling/Mold setup and trial shot.

6. Injection molding for the plastic parts.

7. Mass production. (price will be very cheap with large quantity)

| Our Advantage |

1.We promise:All the parts from our company have no sharp edge. All dimensions are controlled according to your drawings. Every product will be fully inspected and carefully packed to prevent the bump and rust in transit .

2. The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart.

3. Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and professional inspectors.

4. Each size of product must be tested one by one after completing production and provide quality report.

5.We have many years of export experience,exports to the US,Europe, Japan and other countries and regions.

6.Our team are professional. We have reasonable price and good quality controlling. And our language ability is also diversified

| About Us |

Foshan Mogel Hardware & Plastic Co., Ltd. was founded initially as a Plastic injection molding and tooling fabrication plant from 2006, afterwards growing quickly and set up Mogel Industry Limited in HK, we have several divisions,focusing on turnkey solutions inclusive of the CNC machining, Punching, Stamping and assembly , Based on our extensive experience and deep understanding of mechanical and plastic components manufacturing,and now become a growing innovative mechanical , plastic components engineering design and manufacturing company.

Mogel group is proud to offer a comprehensive suite of compact and cost-effective products to our partners, monitoring and maintenance operations with the utmost in quality. Our factory are engaged in mechanical and plastic components manufacturing over 10 years with our goal to leverage on our synergetic capability to add value to our customer and grow the business together.

Strict inspection we do during operation

- Experienced QC testers to check the products dimension, surface and performance according to drawings specification.

- Experienced IQC to check the dimensions and surface of the incoming material.

- Experienced PQC to inspect full-course during the processing.

- Experienced FQC to inspect all the plating products from outsides and make the 100% inspection before the shipments.

Quality sample will be provided for your testing before production according to ISO 9001: 2008.

We are pleased to service you with excellent quality, reasonable cost and grow withyou together.

order history:

| FAQ |

Q1.How to have my components quoted ?

A1: Please contact us via TradeManager or Email and send us your drawings inclusive of 2D and 3D (.STEP or .IGE file) and detail requirements. We are pleased to sign NDA with you if you prefer. Then our engineering team will work on them and submit competitive quotation to you.

Q2.What is the lead time for tooling and samples fabrication?

A2: The exact lead time depends on your parts specification.

The normal lead time is 40*45 days for tooling fabrication and samples.

If the tooling is not required, the lead time for samples is 15 days normally.

Q3.Can I have prototypes for testing before tooling ?

A3: Yes, our factory have team to support prototypes with machining process to fabricate them for your testing.

Q4.How to ship the samples and production order ?

A4: We will normally ship samples via DHL, UPS or FedEX via our cooperated forwarder or freight collect. For the shipping of production order, it will be by sea or by air

Q5.How to ensure the quality of parts?

A5: Firstly, our team will inspect all incoming material. QC team will inspect parts while production and finished products, then submit Quality Inspection Report together with samples and production order.

| CONTACT US |

| Tel | +86-13509967887 |

| penny@mogell.com |