Пластиковая литьевая машина для литья под

- Категория: Plastic Injection Machines >>>

- Поставщик: Guangdong,Newgoer,Instrument,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.38 $* | 0.36 $* |

| Aug-16-2025 | 0.78 $* | 0.41 $* |

| Jul-16-2025 | 0.40 $* | 0.50 $* |

| Jun-16-2025 | 0.29 $* | 0.68 $* |

| May-16-2025 | 0.61 $* | 0.39 $* |

| Apr-16-2025 | 0.76 $* | 0.15 $* |

| Mar-16-2025 | 0.19 $* | 0.58 $* |

| Feb-16-2025 | 0.16 $* | 0.71 $* |

| Jan-16-2025 | 0.88 $* | 0.84 $* |

Характеристики

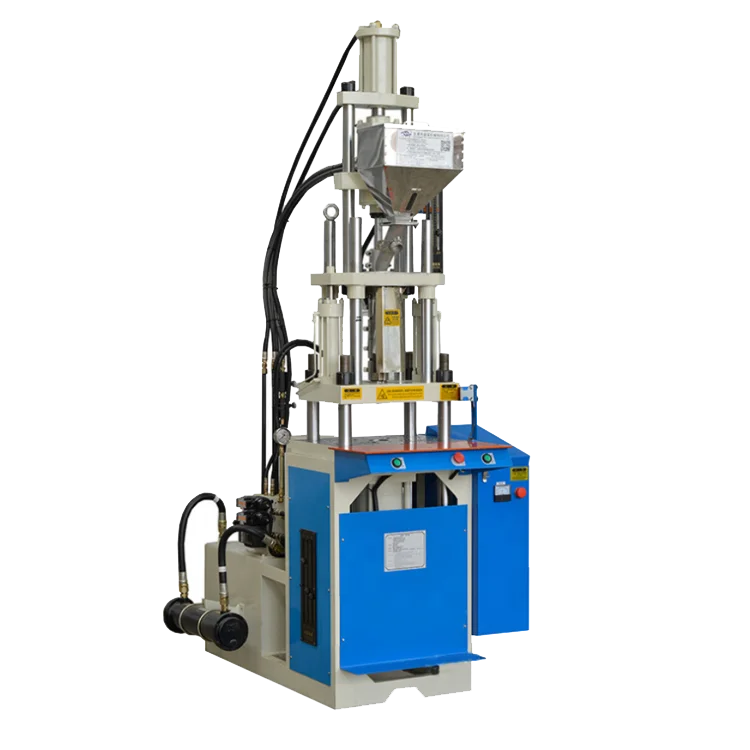

Lab Small Plastic Vertical Injecting Molding Machine,

Plastic Making Machine Injection Molding Machine Factory

Summary:

Plastic injection moulding is the process of melting plastic pellets (thermosetting/ thermoplastic polymers) that once malleable enough, are injected at pressure into a mould cavity, which fills and solidifies to produce the final product.

Features:

1.Vertical mold opening and vertical injection, suitable for insert molding.

2, Nitrided mast, material tube, high torque night pressure motor drive, multi-stage injection pressure, good plasticizing performance.

3, Direct pressure mother-mother lock cylinder design, rapid mold clamping, low-pressure safety mold clamping, abnormal automatic mold opening, multiple pressure control, high safety, improve mold life.

4, Electrical warranty device, no mistakes occur, maintenance operators safe.

5, Automatic fault display, maintenance is quick and easy.

6, Electronic control, night pressure face using brand-name parts, quiet, precise and durable.

7, Multi-stage temperature control, multi-stage injection pressure, injection speed, back pressure stepless adjustment, suitable for precision plastic parts molding.

Speficiations:

| Screw Diameter | Mm | 26 | 28 | 30 |

| Injection Pressure | kg/cm² | 1530 | 1278 | 886 |

| Theoretical Shot Volume | cm³ | 61 | 70.8 | 81 |

| Max.Shot Weight(ps) | g | 56 | 64 | 74 |

| Safe Shot Weight(ps) | OZ | 2 | 2.27 | 2.6 |

| Max.Shot Weight(ps) | cm³/sec | 57 | 66 | 75.5 |

| Injection Rate | mm | 115 | ||

| Screw Speed Max. | rpm | 0-205 | ||

| Nozzle Comtact Force | Tons | 4.45 | ||

| Nozzle Retraction Stroke | mm | 170 | ||

| Clamping Force | Tons | 35 | ||

| Platen Size | mm | 540*380 | ||

| Distance between tie bere | mm | 375*205 | ||

| Min.Mold Height | mm | 158/58 | ||

| Opening Stroke | mm | 180 | ||

| Max.Open Daylight | mm | 338/238 | ||

| Ejetor Force | Tons | 1.3 | ||

| Ejetor Stoke | mm | 35 | ||

| Max.Hydaulic Pressure | kg/cm² | 140 | ||

| Pump Output | l/min | 34.5 | ||

| Oil Resservoir Capacity | l | 100 | ||

| Cooling Waer Consumption | l/hr | 400-600 | ||

| Pump Motor Power | KW/HP | 3.75/5.5HP | ||

| Berrel Heating Power | KW | 2.4 | ||

| Total Electricity | KW | 6.3 | ||

NEWGOER though 20 years of continuous development, our company has established the main products line of Universal strength testing machines for tension, compression, flexure, and shear etc. Environmental testing chambers and Cell phone, Computer and 3C Electronics testing machines, Package and paper test equipment, Plastic and Rubber Test Equipment, Leather and Shoes Testing Machine and so on! Our equipment is used in over 80 countries worldwide and supported by a network of offices and approved agencies. Our products are used in all industries and educational sectors and we have an enviable reputation for innovation, quality product and excellent customer support !

Our Factory

We have professional packing teams and shipping forwarder to pack and deliver your products!

Packing:

1. Out packing:Standard export wooden case.

2. Inner packing:With careful stretch film wrap product, hard wood board+ strong bandage to fix corners.

3. Checking teams: Specialized staff to inspect and classified your goods.

Shipping:

You can specify other shipping methods such as Airmail, FEDEX or DHL. We shall let you know about the shipping cost after receipt ofyour order. It's more preferable for you to provide us with your own FEDEX/DHL account number so that the delivery charge can be charged directly from your account.

Lab Small Plastic Vertical Injecting Molding Machine, Plastic Making Machine Injection Molding Machine Factory

1.Are your company a trading one or a factory ?

Factory + trade (integration), 20 years focusing on test instruments field, 6 years exporting experience.

OEM is also acceptable for us.

2.How to choose the most suitable products?

Our professional team will give you the best suggestion as long as you tell us what kind of test you

need to do and the required specification.

3.What’s the delivery term?

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15-20

working days after deposit receipt. If you are in urgent need, we can consider making special

arrangement for you.

4.Do you accept customization service?

Yes, of course, we can not only offer standard machines, but also customized machines according to

your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

5.Can we visit your factory before order?

Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to

arrange hotel and pick up you from airport.