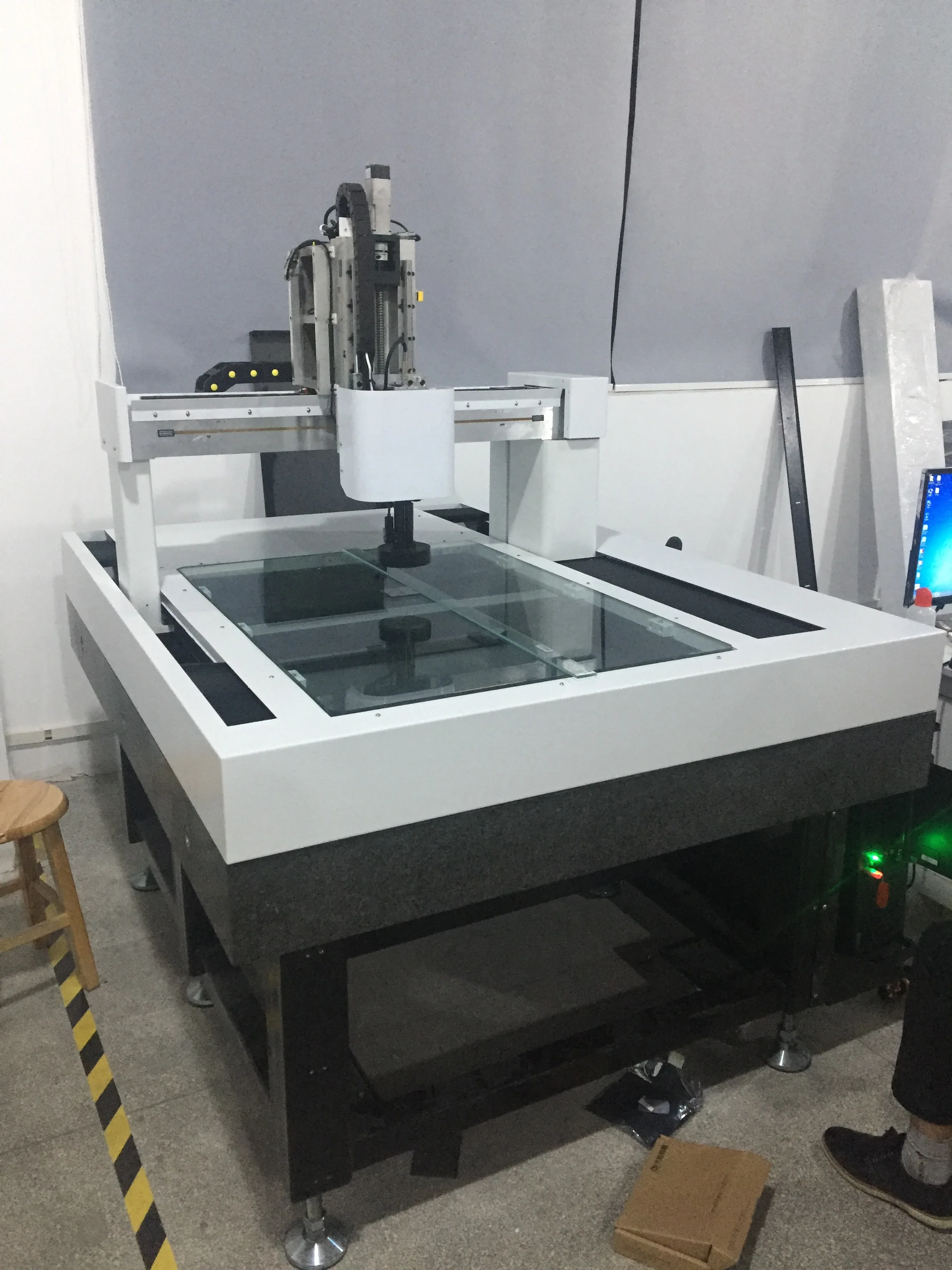

Система координат 3D CMM машина для

- Категория: Other Optics Instruments >>>

- Поставщик: Dongguan,Zhongli,Instrument,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.47 $* | 0.15 $* |

| Aug-16-2025 | 0.90 $* | 0.7 $* |

| Jul-16-2025 | 0.81 $* | 0.30 $* |

| Jun-16-2025 | 0.62 $* | 0.25 $* |

| May-16-2025 | 0.65 $* | 0.88 $* |

| Apr-16-2025 | 0.6 $* | 0.39 $* |

| Mar-16-2025 | 0.6 $* | 0.59 $* |

| Feb-16-2025 | 0.72 $* | 0.57 $* |

| Jan-16-2025 | 0.80 $* | 0.13 $* |

Характеристики

Coordinate System 3D CMM Coordinate Measuring Machine

Product introduction:

The image measuring instrument can accurately measure points, lines, circles and other elements, and has a powerful report output function, which is especially suitable for measuring a wide range of products in large quantities.

Widely used in machinery, electronics, molds, injection molding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision hardware, precision stamping, connectors, connectors, terminals, mobile phones, home appliances, computers (computers), liquid crystal televisions (LCD), printing Circuit boards (circuit boards, PCB), automobiles, medical equipment, clocks, instruments, and other industries.

Measurement object:

LCD, FPC, PCB, circuit boards, screws, springs, watches, watches, meters, connectors (connectors, terminals), gears, cams, threads, radius templates, thread templates, wires and cables, tools, bearings, hardware , Stamping parts, screens, test screens, cement screens, mesh panels (steel mesh, SMT template), etc.

Measuring element:

Length, width, height, hole distance, spacing, Pin spacing, thickness, arc, diameter, radius, groove, angle, R angle, etc.

Parameter:

Model | 5040 | 6050 | 8060 | |

Stroke(mm) | 500X400X200 | 600x500x200 | 800x600x200 | |

Machine size (mm) | 1150×1500×1700 | 1250x1700x1700 | 1425x2100x1700 | |

Machine weight (kg) | 1100 | 1450 | 1800 | |

Glass table loading weight(kg) | 30 | 30 | 30 | |

X ,Y measure accuracy (μm) | 3.0+L/200 | |||

Z measure accuracy(μm) | 5.0+L/200 | |||

X,Y Axle Run speed | 0-600mm/S(selection) | |||

Z Axle Run speed | 0-100m/S(Selection) | |||

Repeated accuracy(mm) | 0.002 | |||

Operation Mode | software | |||

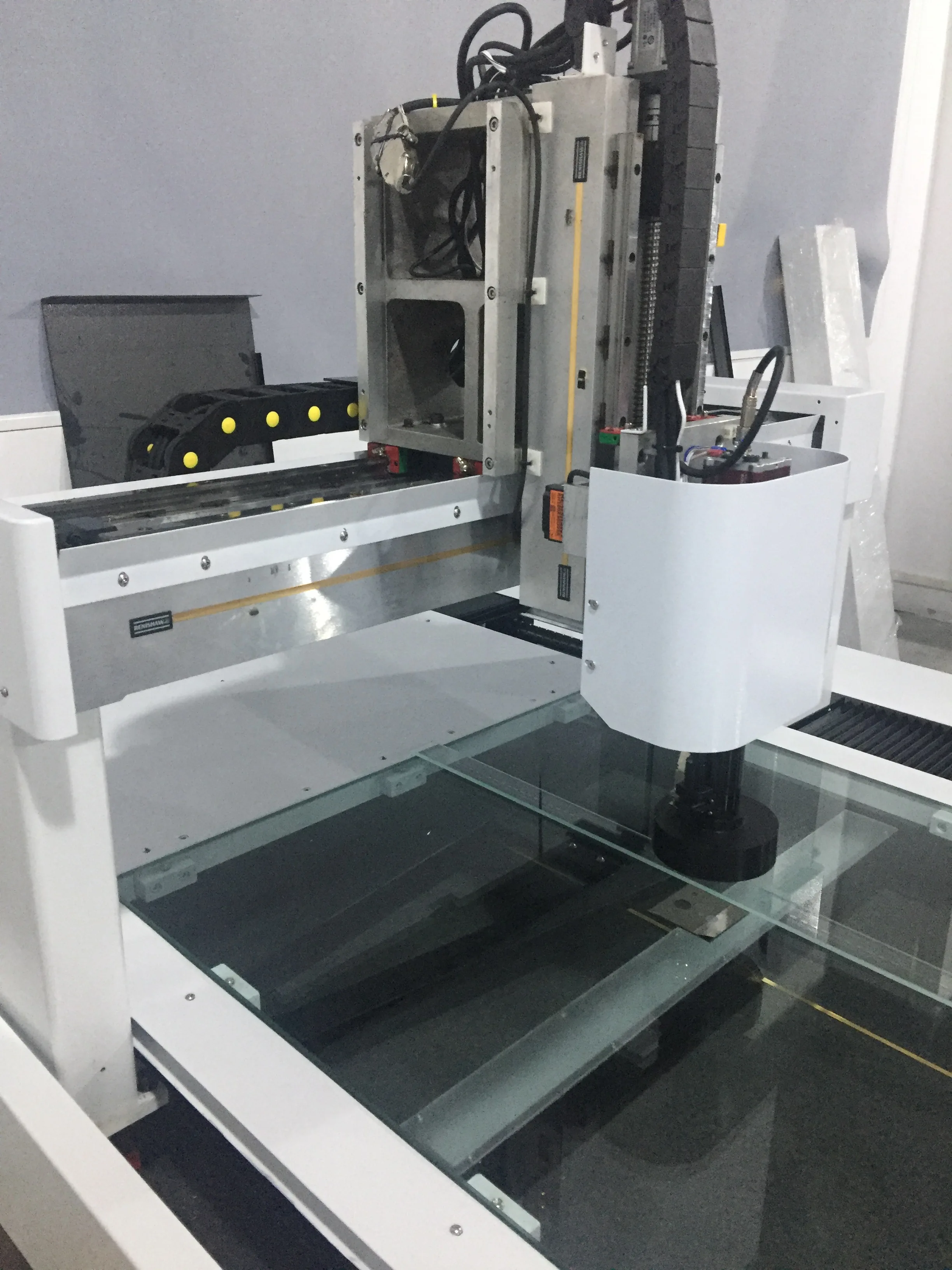

Grating Ruler | 0.001mm resolution “Renishaw” Glass Rating | |||

Guide Rail | Taiwan “Shangyin: class super precision (walking parallelism precision 0.002mm) linear guide | |||

lead screw | Taiwan TBI ” grinding ball screw | |||

Bearing | Japan original "NSK" double case combination centripetal ball bearing | |||

Motor | Japan”Panasonic”AC servo motor | |||

Motion Controller | ZL4000(Full closed-loop controller) | |||

Photoelectrical limit switch

| Japan original "omron" photoelectric limit switch | |||

Camera | SBK-HC536 1/2inch 700 color high definition camera (with white balance function) | |||

Video Card | High resolution dual channel color card | |||

Light Source | Rim Light | Profile LED cold light source, transmission light and condenser lens to realize parallel light irradiation | ||

Surface Light | Fourth ring do not go to the LED cold light source, each area independent program control, 256 levels of brightness programmable adjustable | |||

· Optical lenses | With navigation function card lens, 1:6.5 ratio | |||

· Magnification Ratio

| Optical Magnification:0.7~4.5×;Image image Magnification:24~158X | |||

Global Positioning System

| Laser position indicator | |||

Rocking Bar | Germany ”MEGATRON”Hall triaxial joystick | |||

Software | Full Automatic + Probe software | |||

Computer | Industrial computer: Intel dual-core CPU,4G memory, 1000G hard disk, DVD drive, 2G independent graphics card, 19.5-inch display | |||

Power | 220V/50Hz/3A | |||

· Working condition

| Temperature 20 ℃ + 2 ℃, the temperature change < 2 ℃ / hr, humidity 30~80% | |||

Special table for video equipment | Built-in switching power supply, controller, motor driver, power control switch, indicator light, emergency stop switch, moving roller | |||

Warranty | 12 months | |||

The image measuring instrument body and application features:

1. High performance Panasonic servo motor motion device to ensure high mute, high precision and high repeatability under high speed operation

2. TPI precision screw, which makes the measurement positioning accuracy accurate and reliable, and the positioning accuracy can reach 0.001mm

3. The column and base are made of high-precision granite structure, which is stable and reliable.

4. Equipped with SBK-CNC multi-function measurement software to increase the measurement speed by 2 times than the AC series automatic image measuring instrument.

5. British "RENISHAW" 0.001mm metal grating, measurement data is more stable and high precision

6. Measurement data can be imported into Word, Excel, AutoCAD, and report output functions, and easy to output test results.

7. With automatic contour scanning, contour tracking, automatic product shape scanning and other functions.

8. Three-axis adopts Taiwan Shangyin precision linear slide rail and TBI high-precision ball screw to ensure machine accuracy and service life.

9. CNC high-definition lens and dedicated high-resolution CCD

Click here >>>> More Factory Prices and Shipping!!!

We are Zhongli Instrument Technology Co., Ltd, an instrument Expert, Headquartered in Dongguan, Guangdong, China.since 2007, specialized in manufacturing Lab testing equipments.

Throughout its more than 13 years of history, Our products have sold well in the Europe, America and Southeast Asia market and total more than 80 countries these years,especially favored by European and American countries.

Our equipments cover a wide range of industries, such as rubber and plastics industry, food industry, packaging industry, electronics industry, etc.and are suitable for all scientific research units, quality inspection institutions and academic fields.

In addition to standard machines, our R&D team can customize it for you. Just tell us your needs and we will make you satisfied.

Click here >>>> More Factory Prices and Shipping !!!

1. How to choose the most suitable Mechanical Equipment ?

Our professional team will give you the best suggestion as long as you tell us what kind of test you need to do andthe required specification.

2. What’s the delivery term?

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15~20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

3. Do you accept customization service?

Yes, of course, we can not only offer standard machines, but also customized machines

according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

4. Can we visit your factory before order?

Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

5. Do you have customers of our country before?

Now our testing machines have been sold to more than 80 countries, like USA, Canada, Russia,UK, Italy, Germany, European , India, Pakistan, Philippine, Singapore, Malaysia,Thailand , Vietnam, Korea,Saudi Arabia,Brazil...and so on.

6. How about your warranty?

Generally,our warranty is two years. Within the warranty period, we can offer technique support and part parts change, necessarily, our engineers may go to your place for better service.

7. How about the packing for machine, is it safely protected during transportation?

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many testing machines abroad by sea or by air without damage.

8. What is the order process?

Inquiry - quotation - communication - order confirming - deposit payment - production - testing and debugging - balance payment - packing - delivery - customer receiving - after service.

9. How to install and use the product?

The product is shipped with an operating instructions and video of English version.

Welcome to visit our Official Website:

www.zltester.com

How to contact us?

Send your inquiry details in the below, click " Send" Now!

Click here >>>> More Information !!!