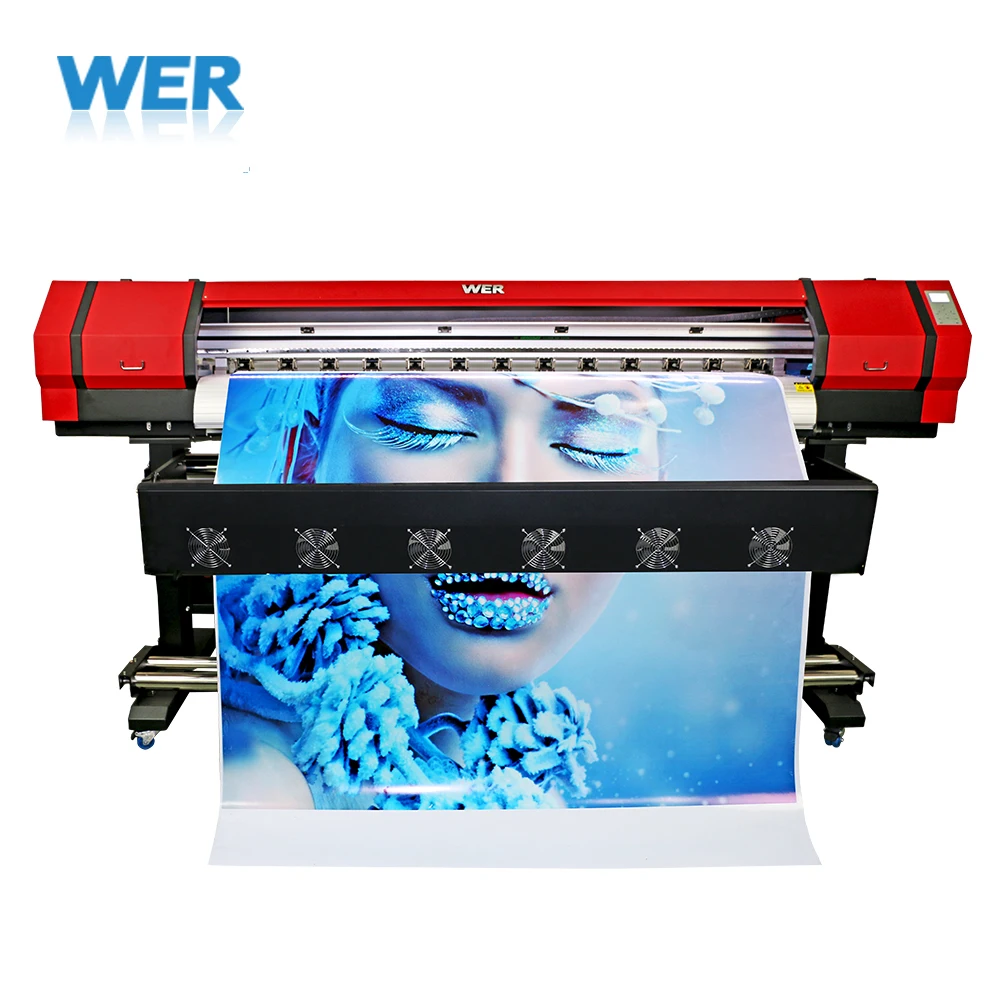

Рекламная печатная машина 5 футов эко-растворитель плоттер принтер уличная печать наклеек чернильные демпферы лента

- Категория: Цифровые Принтеры >>>

- Поставщик: Shanghai,Wer-China,Industry,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 3308.83 $* | 3473.99 $* |

| Aug-16-2025 | 3280.51 $* | 3444.30 $* |

| Jul-16-2025 | 2752.43 $* | 2890.58 $* |

| Jun-16-2025 | 3225.33 $* | 3386.62 $* |

| May-16-2025 | 2808.40 $* | 2948.68 $* |

| Apr-16-2025 | 3169.13 $* | 3327.4 $* |

| Mar-16-2025 | 3141.48 $* | 3298.77 $* |

| Feb-16-2025 | 3114.86 $* | 3270.23 $* |

| Jan-16-2025 | 3086.61 $* | 3240.94 $* |

Характеристики

Details

| Specification of 1.6m eco solvent printer | |||

| Model | WER-ES160 | ||

| Print Technology | Drop-On-Demand Piezo electric Technology | ||

| Number of print-heads | 1 pcs Epson XP600 | ||

| Color | C M Y K | ||

| Resolution | 1440 dpi | ||

| Ink type | Piezo Eco solvent ink | ||

| Ink supplying system | Auto ink supplying system | ||

| Maintenance of the Printhead | One button cleaning printhead by solvent | ||

| Assistant option | Auto feeding and take up system | Equipped | |

| Heating system | Stage heating system incluidng back , front heating | ||

| Carriage height | 2-5mm distance to be printing platform adjustable | ||

| Other Function | Light for carriage position | ||

| Media accetpable | Flex Banner, mesh, PVC vinyl, photo paper, PP paper, backlit film, wall-paper,window film etc. | ||

| Print width max | 1600 MM | ||

| Speed | Mode | 17 m2/h | |

| Production mode | 13 m2/h | ||

| Quality mode | 9 m2/h | ||

| Ultra quality mode | 6.8 m2/h | ||

| Interface | USB 2.0 | ||

| RIP Software | Maintop, Photoprint | ||

| Linear rail | THK linear rail | ||

| Operation Valtage | AC 220 V 50/ 60 Hz | ||

| Power | 500w printing system ,500W heating system( Fron heating 500w ,Rear heating 500w, Back heating 1000W) | ||

| Working environment | Temperature: 22℃ ~ 28℃; Humidity: 40% ~ 70% | ||

| N.W. | 200kg | ||

| Machine Size | 2940mm*600mm*1230mm | ||

| Packing G.W. | 240KG | ||

| Packing Size | 3000mm * 700 mm * 600 mm | ||

| MOQ 1 SET | 1 Set | ||

| Leading time | Within 10 working days after receiving your deposit | ||

| Payment Terms | 40% TT in advance for deposit , the balance should be paid before delivery | ||

Fetures

1. Precise media feeding system guarantee the accurate media delivery.

2. Adopt Imported linear rail guide system & alloy metal beam enable machine more precising running;

3. Automatic cleaning & capping system give the best protection for print-heads.

4. The distance between media and carraige can be adjusted for media in different thickness

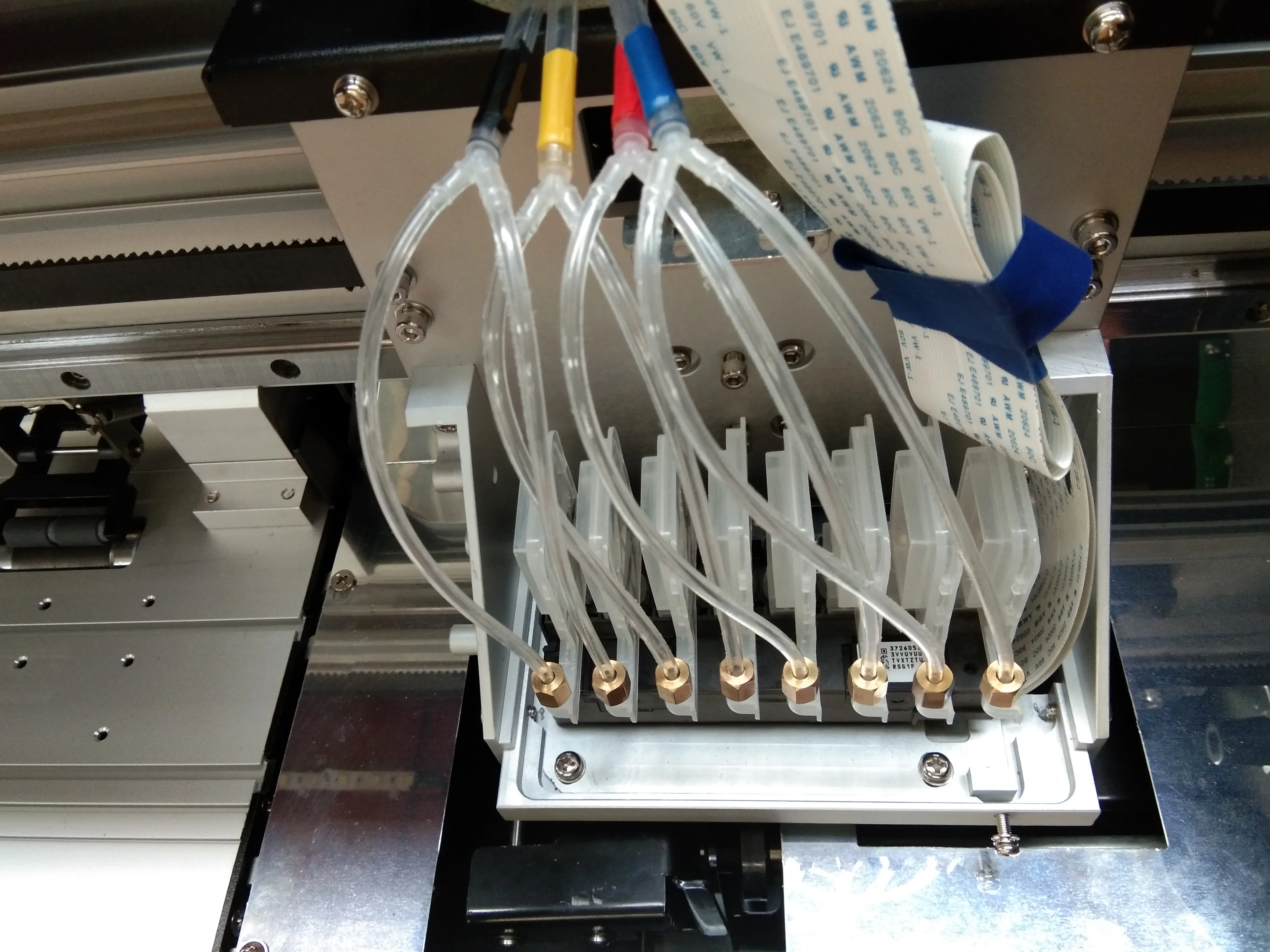

| Epson XP600 Printhead Instruction: Epson XP600 Resolution: 1440DPI Color: 4 colors Print mode: 4, 6, 8, 12 Pass Notes: A: Operators need to make antistatic treatment, please wear the Anti-static devices if permission, to prevent the high static load from burning the circuit board inside print head. B: During installation, try not to directly touch the surface of print head. | |

| Eco solvent printer main board Introduction: EPSON XP600 eco solvent printer main board. Usage: Send printing data signal, control the operations of main parts. Notes: A: Resist dirt and moisture for the main board. B: Turn off the power when check the main board. Mark the plug signal line and supply line to avoid connection mistake which can burnout the main board. C: Please do not break or weld the spare parts on the main board personally. |  | |

| Eco solvent printer print head board Introduction: XP600 eco solvent printer print head board. Usage: Receive printing data signal and control inkjet and voltage of the print head. Notes: A:Resist dirt and moisture for the print head board. B: The print head cable must be inserted into the right place; otherwise it may burnout the print head. C: Please do not weld or dismount any spare part on the print head board personally. | |

| Sheet feeder Introduction: Auto-feed, keep the material tension balance, make the material pass through the print platform smoothly and do nice printing work. Notes: A:. When printing materials, rigidly fix the material and sheet feeder shelf. B: Try to put the material in middle of the platform, make the material get equal force by the roller, so it can pass through the print platform smoothly. C:Keep a clean and tidy environment surrounding the sheet feeder; do not interfere with the feeding process. |  | |

| ||

| Ink cartridge Introduction: 2 Liter ink cartridge, provide the ink continuously which is very convenient. Ink color is clear, so it is not easy to add the wrong color ink. Notes: A: Make sure each color ink to the corresponding ink cartridge. B: It is enough when the ink reaches 3/4 of the cartridge. C: Be careful not to dirty machine and ground when add ink; seal the lid on time after add ink. | ||

| Suction and heating device Introduction: Automatic suction when printing which can make the print materials adsorb to the platform better, so the heater can heat and dry the printed material more evenly. Notes: A: Keep the suction plate clean and tidy. B: Adjust the suction strength before printing, as well as proper heating temperature. C: Do not touch the heating plate when printing. |  | |

Application

can not only print on PVC Flex banner, vinyl sticker, tarpaulin thus common outdoor medias, they can also print on artist canvas, pear banner, beach banner, roll up banner, advertising tents, wall paper and wall sticker, photo paper, PP paper, feather flag, teardrop flag, Tension fabric etc.

Photo Paper Sheet Sublimation Fabric Backlit Flex Banner

Roll Photo Paper Lightbox Fabric Rigid Pet Film

Backlit Fabric Sublimation Direct Jet Fabric Frontlit PVC Film

Company Information

Superiority

1. Low MOQ: It can meet your sample display business very well.

2. OEM Accepted: The products can be customized

3. Good Service: No any excuses for 24 hours service

4. Good Quality: We have strict quality control system, good reputation in the market

5. Fast & Cheap Delivery: We have big discount from forwarder and aircargo (Long Contract)

Our Innovation

1.Quality & Service: At WER, our priority has been providing our customers with great quality products and superior customer service with no excuses.

2.Quick Lead Time: We're dedicated to completing all orders in the fastest time with commitment.

3.Competitive Prices We continuously strive to find ways of reducing our production costs, and lower the purchase cost for you.

4.Brand Awareness: The goal of any strong brand is achieve a level of awareness that delivers the idea of quality, value, service and responsibility to all of your potential customers.

5.Special Offers: In order to maintain our competitive edge, we are running special offers on our promotional products, consumable parts and customized services. Please contact our sales team to see how we can help you save a lot of money.

Excellent After-sale Services

1.One year warranty

You can discuss operation and maintenance with our technician online support service by Skype, MSN etc. Remote control will be provided upon request.

2. Free exchange of new components

Our quality is guaranteed 100%, the spare parts can be replaced within one year free of charge includes the airfreight by express, except for the print head and some consumable parts.

3. Convenient online consultation

The technician will keep online. No matter what kind of technical questions that you may have, you would get a satisfactory answer from our professional technician easily.

4. Free onsite installation and training

If you are able to help us with getting the visa and also would like to bear the costs involved like flight tickets, food, etc, we can send our technician to your office, and to give you a free installation and training for as long as you know how to operate it.