Высококачественная шлифовальная машина для поверхностного пола WCG 650 цемента бетона эпоксидной

- Категория: >>>

- Поставщик: WCG,(Xiamen),Industrial,Grinding,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 4510.87 $* | 4736.69 $* |

| Aug-16-2025 | 4472.88 $* | 4696.3 $* |

| Jul-16-2025 | 3752.36 $* | 3940.71 $* |

| Jun-16-2025 | 4396.78 $* | 4616.83 $* |

| May-16-2025 | 3828.10 $* | 4019.23 $* |

| Apr-16-2025 | 4321.63 $* | 4537.66 $* |

| Mar-16-2025 | 4283.33 $* | 4497.96 $* |

| Feb-16-2025 | 4245.83 $* | 4457.29 $* |

| Jan-16-2025 | 4207.6 $* | 4417.6 $* |

Характеристики

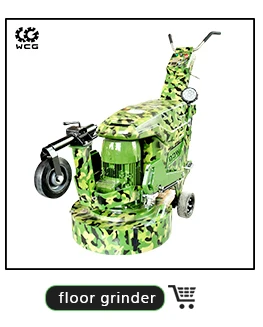

High Quality Surface Floor Grinder WCG 650 for Cement Concrete Epoxy Cover Grinding Machine

| Model Number | Concrete Floor Grinder (WCG 650) |

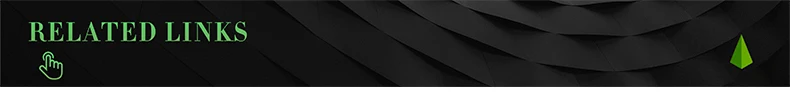

| Working Width | 650 mm(348mm*4) |

| Rotating Speed | 350-1680rpm |

| Voltage | 220V-240V 3P |

| Power | 11Kw/15hp |

| Inverter | 15kw/20hp |

| Weight | 443KG |

| |

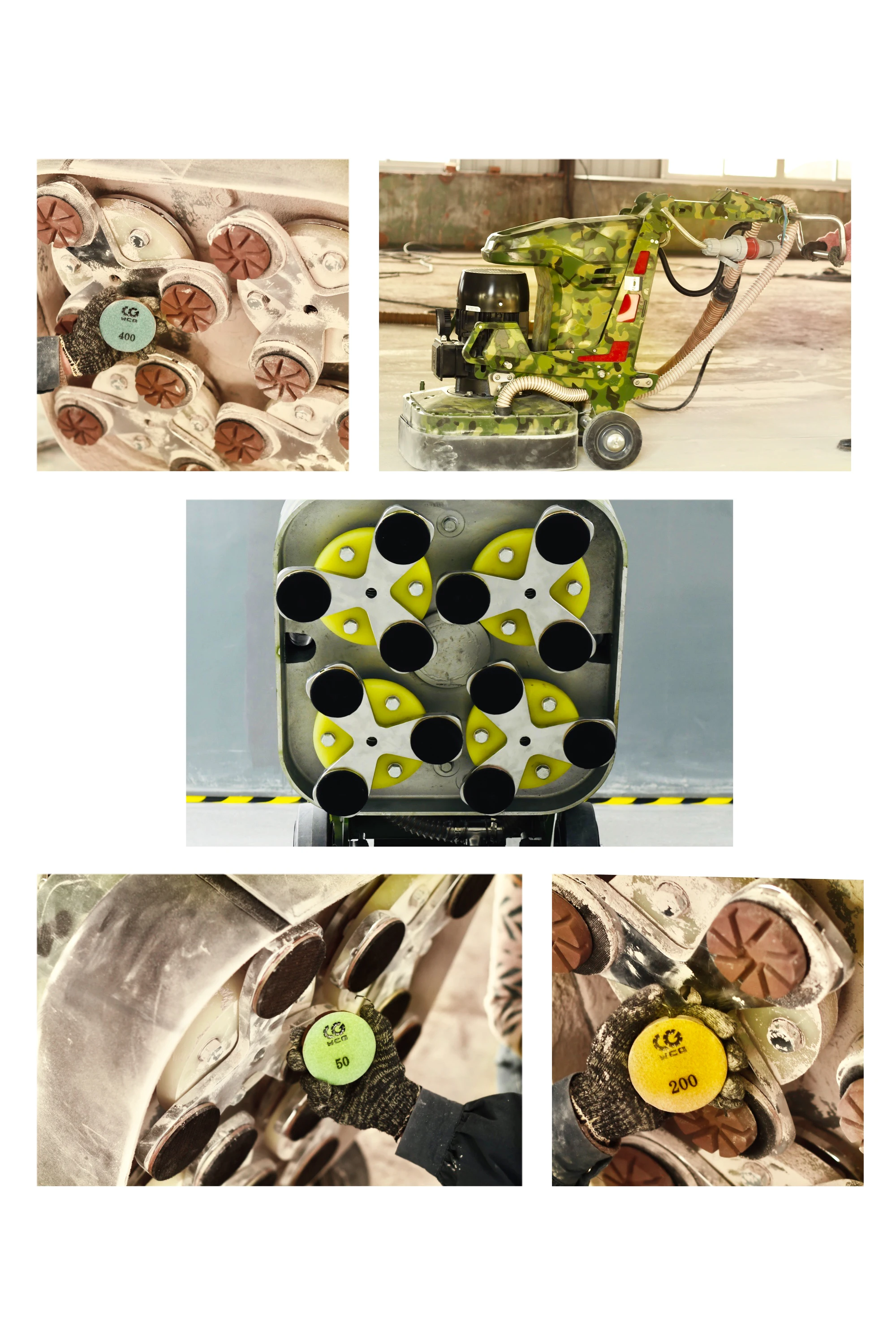

1. The shape is designed by professional industrial team, camouflage color, the atmosphere is more mysterious

2.5 gears design, transmission is more efficient and durable

3. International brand WEG motor, global warranty

4. International brand Delta inverter

5. Using international Siemens buttons, more durable

| Self-propelled floor grinder: Germany imported drive system, grinding process boosts operation, saves labor and time, and makes operation easier. |

| Gear drive system: Grinding is more precise and more efficient, solving the two problems of motor consumption caused by a belt drive and belt slip. Gears - produced by Swedish Reischauer and Taiwan high precision CNC machine. The new gearbox is newly designed, waterproof and dustproof, and has excellent sealing performance, which increases the service life of the internal components and improves the grinding precision. |

| Floating dust shroud: The height of the dust cover can be automatically adjusted according to the abrasive consumption situation and the ground height difference. When change abrasive, the dust cover does not fall off, which can save time and effort. What's more, improve the vacuum efficiency of the industrial vacuum cleaner. |

| Rechargeable battery: Charging during work, external 220v charging, can use for 30 minutes. |

| 25°Slope grinding: Can grind up to 25-degree ramp for underground parking. |

WCG was registered in 2020 in the USA as a trading company, as the world’s factory—China, WCG register a branch without exception, called WCG(XIAMEN) INDUSTRIAL GRINDING CO., LTD., after 10 months of business negotiations, WCG succeed to cooperated with a unicorn enterprise in China who has been the driving force behind the growing floor grinding industry for more than 20 years, more than 200 international patents have been obtained until now, thousands of the machines are transported to more than 150 countries every year, WCG came into being under such circumstances. floor grinder

WCG began from several founding partners, one of them is ESP Soluções Industrial, which specialized in industrial and commercial resin floors since 1993 in Brazil, “We have a client portfolio that includes the largest companies in the country, there have been many successful cases over these two decades.” said by second-generation heir Mr. Clauderson Pereira, all these bases enabled WCG to began as a successful enterprise and ensure that you will get a cost-effective solution, WCG has been working on achieving hard floors to be worked in an entirely new way, this was the result of the company’s strong talents in innovation, and it filled a clear need in the market, “THE WAYS YOU HEAR THE SOUND OF A GEARBOX, BEYOND YOUR DREAMS”, what another partner said.concrete floor grinder

1. Which one is a better gear-driven type or belt drive type? |

The gear-driven type has super durable and reliable characteristics to ensure a long MLV(machine lifetime value). WCG uses the aluminum alloy material for the gearbox to make sure that all floor grinders are strong enough for machines to work continuously with high efficiency.epoxy floor grinder WCG R&D team found that most floor grinders are using a belt-driven system, of course, we admit that a belt-driven system is easy to use and cost-effective, but its drives not compact and got a very short life compared with other power transmissions, the most important is that the velocity ratio varies because of belt slip, so the belt-driving system can not control the grinding precision very well.floor grinder concrete However, the gear-driving system is positive and non-slip drives, they got large and constant velocity ratio of 60:1, can be obtained by using gear trains with minimum space, compared to the belt and chain drives, they are the most compact, so the gear-driving system has high transmission efficiency, the perfect gear planetary rotation system successfully developed by WCG that has passed the 19999-hour test will escort your project. |

2. Can you leave concrete floors bare? |

Bare concrete floors might often be the cheapest option, but they can lead to a whole host of problems that could incur more costs, hassle, and lost time than installing a coating in the first place.concrete grinder machine floor |

3. What are the best shoes to wear on concrete floors? |

The best shoes for walking or working on concrete floors are Timberland PRO Men's Sports Shoes and Skechers Men's Glides Calculous Loafer. They are comfortable athletic work shoes for walking / standing on the concrete floors for long hours. |

4. Is unsealed concrete toxic? |

When you leave your concrete warehouse floors unsealed, the concrete will produce flecks of concrete dust that can coat machinery, create a dirty work environment, wreaking havoc on manufacturing, and even cause health issues. It's simply unavoidable and a very real issue unless you seal the floors. |

5. Why need a concrete floor grinder? |

When it comes to all-in-one construction tools, a concrete floor grinder is a must. Whether the job involves grinding down uneven concrete slabs, leveling joints, removing stubborn tile, vinyl glue, paint, or giving a concrete surface a smooth appearance or even cleaning industrial contaminants, these powerful machines eliminate the need for chemical etching, making quick work out of concrete surfacing jobs both big and small. |