Износостойкий фарфоровый глазной направляющий провод 95 глиноземный керамический глаз для текстильной промышленности круговая

- Категория: Запчасти текстильных станков >>>

- Поставщик: Shanghai,Qipang,Industrial,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.94 $* | 0.0 $* |

| Aug-18-2025 | 0.35 $* | 0.52 $* |

| Jul-18-2025 | 0.2 $* | 0.53 $* |

| Jun-18-2025 | 0.29 $* | 0.38 $* |

| May-18-2025 | 0.92 $* | 0.22 $* |

| Apr-18-2025 | 0.14 $* | 0.32 $* |

| Mar-18-2025 | 0.3 $* | 0.36 $* |

| Feb-18-2025 | 0.47 $* | 0.75 $* |

| Jan-18-2025 | 0.73 $* | 0.67 $* |

Характеристики

Product Description

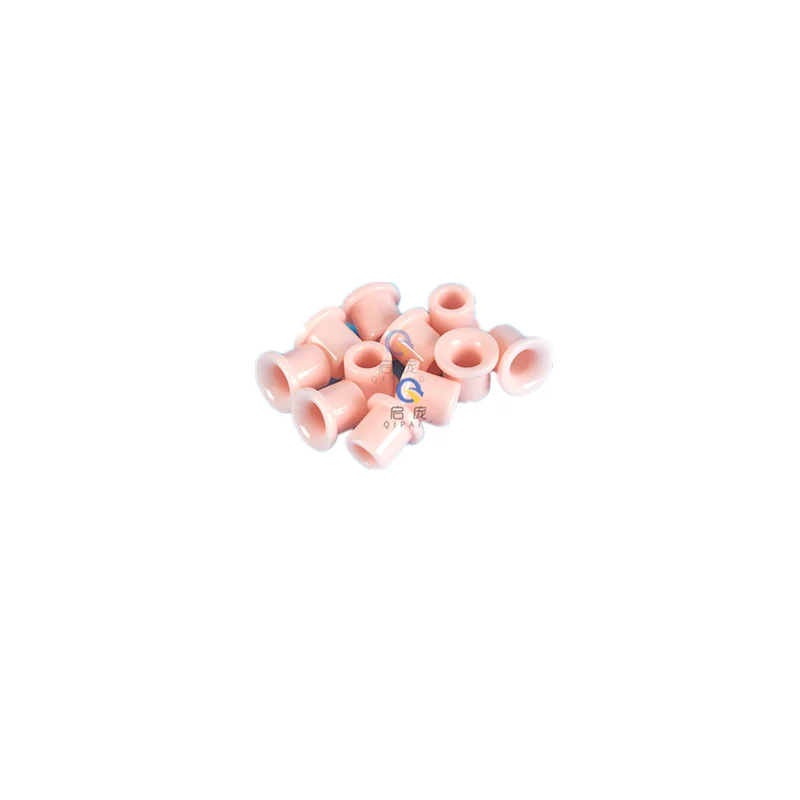

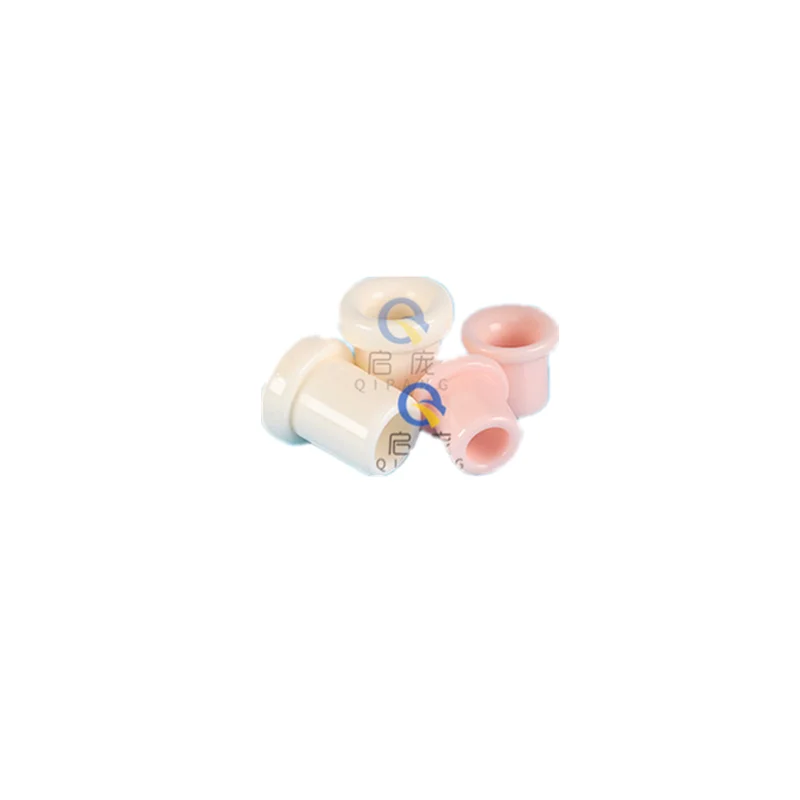

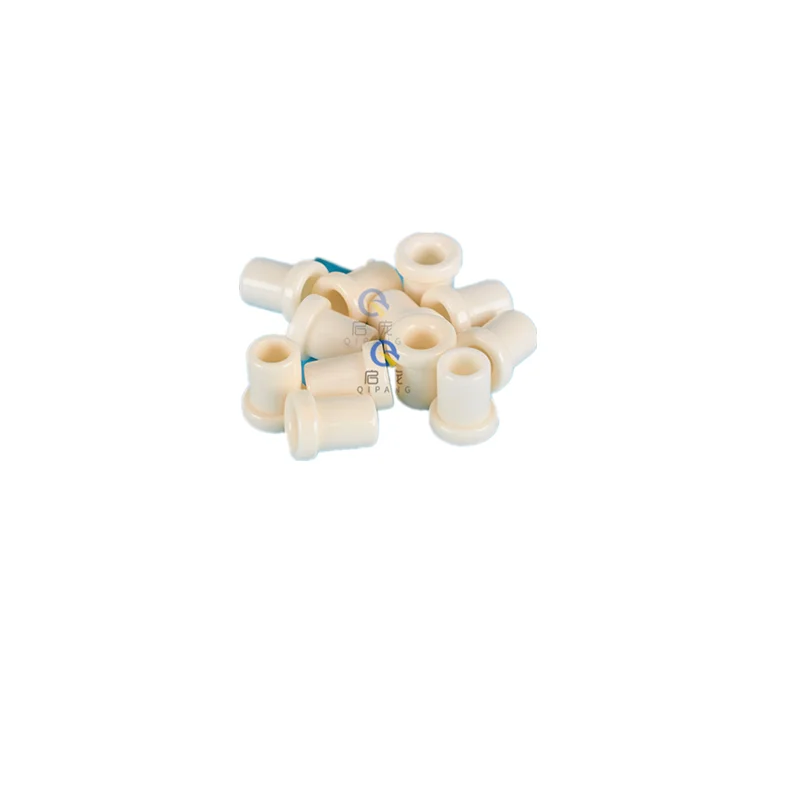

95 Alumina Wear_resistant Ceramic Eye For Textile Industry Porcelain Eye Stranding Machine Guide Wire

Alumina ceramics mainly includes alumina , which applies to thick film integrated circuits. Alumina ceramics have good conductivity, mechanical strength and high- temperature resistance. Alumina ceramics is widely used in all sorts of field to meet the needs of daily use and special performance.Alumina electrical ceramics have low dielectric constant, low dielectric loss, high insulation strength, high volume resistivity, good bending strength, high stability, high compressive strength and good cold and hot shock denaturation. It is widely used in temperature controllers, insulation parts, thermal equipment, electric heating equipment, iron structure buildings, shipbuilding, etc.

Classification of alumina ceramics:

High-purity alumina ceramics are ceramic materials containing more than 99. 9% aluminum. Because their sintering temperature is as high as 1650-1990℃ and transmission wavelength is 1-6MM, they are generally made into molten glass instead of platinum crucible. It can be used as sodium lamp tube according to its light transmittance and alkali metal corrosion resistance ; It can be used as integrated circuit substrate and high frequency insulating material in electronic industry.

Ordinary alumina ceramics are divided into 99 porcelain, 95 porcelain, 90 porcelain, 85 porcelain, etc. according to different aluminum content, and sometimes those with aluminum content of 80% or 75% are also classified as ordinary alumina ceramics. Among them, 99 alumina porcelain material is used to make high temperature crucible, refractory furnace tube and special wear-resistant materials, such as ceramic bearings, ceramic seals and water valve plates; 95 alumina porcelain is mainly used as corrosion-resistant and wear-resistant parts; 85 porcelain is often doped with talc, which improves its electrical properties and mechanical strength. It can be sealed with molybdenum, niobium, tantalum and other metals, and some of them are used as electric vacuum devices.

Zirconia ceramics are white, yellow or gray when containing impurities, and generally contain HfO2, which is difficult to separate. There are three crystalline States of pure ZrO2 under normal pressure. The production of zirconia ceramics requires the preparation of powders with high purity, good dispersibility, ultrafine particles and narrow particle size distribution. There are many preparation methods of ultrafine zirconia powders. The purification of zirconia mainly includes chlorination and thermal decomposition, alkali metal oxidation decomposition, lime melting, plasma arc, precipitation, colloid, hydrolysis and spray pyrolysis.

Zirconia ceramics, ZrO2 ceramics and Zirconia ceramics have excellent properties such as high melting point and boiling point, high hardness, insulator at normal temperature and conductivity at high temperature.

Zirconia ceramics have the advantages of high toughness, high bending strength, high wear resistance, excellent thermal insulation performance and thermal expansion coefficient close to steel, so it is widely used in the field of structural ceramics. It mainly includes: Y-TZP grinding ball, dispersing and grinding medium, nozzle, ball valve seat, zirconia mold, miniature fan axis, optical fiber pin, optical fiber sleeve, wire drawing die and cutting tool, wear-resistant cutter, clothing button, watch case and watchband, bracelet and pendant, ball bearing, light hitting rod of golf ball and other wear-resistant parts at room temperature.

In the aspect of functional ceramics, its excellent high temperature resistance can be used as induction heating pipes, refractory materials and heating elements. Zirconia ceramics have sensitive electrical performance parameters, which are mainly used in oxygen sensors, Solid Oxide Fuel Cell, SOFC) and high-temperature heaters. ZrO2 has a high refractive index (n-21 22). By adding certain coloring elements (V2O5, MoO3, Fe2O3, etc.) into ultrafine zirconia powder, it can be made into colorful translucent polycrystalline ZrO2 material, which shines like natural gems and can be made into various decorations. In addition, zirconia is widely used in thermal barrier coatings, catalyst carriers, medical treatment, health care, refractory materials, textiles and other fields.

High-purity alumina ceramics are ceramic materials containing more than 99. 9% aluminum. Because their sintering temperature is as high as 1650-1990℃ and transmission wavelength is 1-6MM, they are generally made into molten glass instead of platinum crucible. It can be used as sodium lamp tube according to its light transmittance and alkali metal corrosion resistance ; It can be used as integrated circuit substrate and high frequency insulating material in electronic industry.

Ordinary alumina ceramics are divided into 99 porcelain, 95 porcelain, 90 porcelain, 85 porcelain, etc. according to different aluminum content, and sometimes those with aluminum content of 80% or 75% are also classified as ordinary alumina ceramics. Among them, 99 alumina porcelain material is used to make high temperature crucible, refractory furnace tube and special wear-resistant materials, such as ceramic bearings, ceramic seals and water valve plates; 95 alumina porcelain is mainly used as corrosion-resistant and wear-resistant parts; 85 porcelain is often doped with talc, which improves its electrical properties and mechanical strength. It can be sealed with molybdenum, niobium, tantalum and other metals, and some of them are used as electric vacuum devices.

Zirconia ceramics are white, yellow or gray when containing impurities, and generally contain HfO2, which is difficult to separate. There are three crystalline States of pure ZrO2 under normal pressure. The production of zirconia ceramics requires the preparation of powders with high purity, good dispersibility, ultrafine particles and narrow particle size distribution. There are many preparation methods of ultrafine zirconia powders. The purification of zirconia mainly includes chlorination and thermal decomposition, alkali metal oxidation decomposition, lime melting, plasma arc, precipitation, colloid, hydrolysis and spray pyrolysis.

Zirconia ceramics, ZrO2 ceramics and Zirconia ceramics have excellent properties such as high melting point and boiling point, high hardness, insulator at normal temperature and conductivity at high temperature.

Zirconia ceramics have the advantages of high toughness, high bending strength, high wear resistance, excellent thermal insulation performance and thermal expansion coefficient close to steel, so it is widely used in the field of structural ceramics. It mainly includes: Y-TZP grinding ball, dispersing and grinding medium, nozzle, ball valve seat, zirconia mold, miniature fan axis, optical fiber pin, optical fiber sleeve, wire drawing die and cutting tool, wear-resistant cutter, clothing button, watch case and watchband, bracelet and pendant, ball bearing, light hitting rod of golf ball and other wear-resistant parts at room temperature.

In the aspect of functional ceramics, its excellent high temperature resistance can be used as induction heating pipes, refractory materials and heating elements. Zirconia ceramics have sensitive electrical performance parameters, which are mainly used in oxygen sensors, Solid Oxide Fuel Cell, SOFC) and high-temperature heaters. ZrO2 has a high refractive index (n-21 22). By adding certain coloring elements (V2O5, MoO3, Fe2O3, etc.) into ultrafine zirconia powder, it can be made into colorful translucent polycrystalline ZrO2 material, which shines like natural gems and can be made into various decorations. In addition, zirconia is widely used in thermal barrier coatings, catalyst carriers, medical treatment, health care, refractory materials, textiles and other fields.

Features of Alumina Ceramic Eyelet Guide

1) A variety of specifications available.

2) Satisfy various technical request

3) Lower medium spoilage

4) Good insulation performance and high temperature resistance

5) Stiffness texture

6) Used in all electric products and electric heating products

We can supply the products according to customer's drawings, samples and performance requirement.

1) A variety of specifications available.

2) Satisfy various technical request

3) Lower medium spoilage

4) Good insulation performance and high temperature resistance

5) Stiffness texture

6) Used in all electric products and electric heating products

We can supply the products according to customer's drawings, samples and performance requirement.

a (outer diameter) | b (height) | c (bore) | d (large outer diameter) |

3.8 | 3.6 | 2.3 | 5.5 |

3.9 | 4 | 2.3 | 5.9 |

4.1 | 8.6 | 2.4 | 5.5 |

4.4 | 3.5 | 2.7 | 6.1 |

5 | 6 | 2.7 | 6.8 |

5.9 | 6 | 3.4 | 7.9 |

7.8 | 11 | 5 | 10.3 |

Specification

Item | value |

Condition | New |

Warranty | 3 months |

Applicable Industries | Other, Textile industry, Hardware |

After Warranty Service | Video technical support, Online support |

Local Service Location | None |

Showroom Location | None |

Video outgoing-inspection | Provided |

Machinery Test Report | Provided |

Marketing Type | New Product 2020 |

Place of Origin | Suzhou China |

Brand Name | QIPANG |

Use | Knitting Machinery |

Type | Nozzle |

Name | Stranding Machine |

Model | QP95 |

Weight | 1 |

Packaging | Carton box/ Wooden box |

Warranty | 6 Months |

Packing & Delivery

Packaging by wooden box for large quantity.

Company Profile

Shanghai QI Pang Industrial Co., LTD.

The company was established in 2009. The company's products include various types of winding machines and accessories such as rolling ring drives, coil winding machines, cable winding machines, textile yarn winding machines, and automatic coil transformer winding machines,extruder assembly line equipment, diameter measuring instrument, etc.

Since its establishment, the factory has always adhered to the principle of quality first and has been developing world-class products. Under the effective operation of the quality assurance system, the quality of products and processed products has been

continuously improved.Our products have won a good reputation in the industry and won the precious trust between new and old customers. Our products sell well at home and abroad, including Europe, America, Southeast Asia, Middle East and other countries

and regions. We pay more attention to the principle of honest management, mutual benefit and customer first. Our company has been working hard to make it more creative and reliable. We sincerely hope to cooperate with new and old friends to create a brilliant tomorrow!

Since its establishment, the factory has always adhered to the principle of quality first and has been developing world-class products. Under the effective operation of the quality assurance system, the quality of products and processed products has been

continuously improved.Our products have won a good reputation in the industry and won the precious trust between new and old customers. Our products sell well at home and abroad, including Europe, America, Southeast Asia, Middle East and other countries

and regions. We pay more attention to the principle of honest management, mutual benefit and customer first. Our company has been working hard to make it more creative and reliable. We sincerely hope to cooperate with new and old friends to create a brilliant tomorrow!

FAQ

1. who are we?

We are based in Shanghai, China, start from 2013,sell to Northern Europe(30.00%),North America(30.00%),South Asia(10.00%),South America(10.00%),Eastern Asia(10.00%),Eastern Europe(10.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

cable winding machine,Pipe bending machine,cable take up and pay off machine,Wire and cable Equipment,Computerrzed Automatic Coiling Machine

4. why should you buy from us not from other suppliers?

In more than 30 years of activities, Comet QIPANG has been able to continue to grow and develop, gaining a world-leading position in the production of equipment for the metal wire, cable and pipe industries.

.

QIPANG has long-term cooperation with import

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,MoneyGram,PayPal,Western Union;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,French

We are based in Shanghai, China, start from 2013,sell to Northern Europe(30.00%),North America(30.00%),South Asia(10.00%),South America(10.00%),Eastern Asia(10.00%),Eastern Europe(10.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

cable winding machine,Pipe bending machine,cable take up and pay off machine,Wire and cable Equipment,Computerrzed Automatic Coiling Machine

4. why should you buy from us not from other suppliers?

In more than 30 years of activities, Comet QIPANG has been able to continue to grow and develop, gaining a world-leading position in the production of equipment for the metal wire, cable and pipe industries.

.

QIPANG has long-term cooperation with import

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,MoneyGram,PayPal,Western Union;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,French