Сертификат CE Очистительная Машина промышленный ультразвуковой очиститель 2000

- Категория: Очистное оборудование >>>

- Поставщик: Keer,International,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.16 $* | 0.20 $* |

| Aug-18-2025 | 0.84 $* | 0.91 $* |

| Jul-18-2025 | 0.88 $* | 0.39 $* |

| Jun-18-2025 | 0.11 $* | 0.3 $* |

| May-18-2025 | 0.96 $* | 0.3 $* |

| Apr-18-2025 | 0.34 $* | 0.63 $* |

| Mar-18-2025 | 0.40 $* | 0.14 $* |

| Feb-18-2025 | 0.54 $* | 0.46 $* |

| Jan-18-2025 | 0.83 $* | 0.63 $* |

Характеристики

KER series Industrial ultrasonic Cleaning Machine

CE certificate ultrasonic cleaner

| Model | Effective Tank Size | Overall Dimensions | Effective Tank Capacity | Ultrasonic Power | Transducer | Heating Power |

| KER-2400 | 600x480x390mm | 1260x980x940mm | 112L/29.6 Gal | 2.4 KW | 100W, 24pcs | 4 KW |

| KER-3000 | 750×550x390mm | 1410x1050x980mm | 160L/42.3 Gal | 3.0 KW | 100W.30pcs | 8 KW |

| KER-4000 | 1000x550x420mm | 1660x1050x1100mm | 231 L/61 Gal | 4.0 KW | 100W, 40pcs | 12 KW |

| KER-6000 | 1200x650x490mm | 1860x1150x1180mm | 382 L/100.9 Gal | 6.0KW | 100W, 60pcs | 15 KW |

| KER-8000 | 1450x720x570mm | 2010x1220×1260mm | 595 L/157.2 Gal | 8.0 KW | 100W,80pcs | 18 KW |

| KER-10800 | 1500x800x640mm | 2060x1300×1330mm | 768 L/202.9 Gal | 10.8KW | 100W, 108pcs | 30 KW |

| KER-12000 | 1700x900x640mm | 2260x1400x1330mm | 979 L/ 258.6 Gal | 12.0 Kw | 100W,120pcs | 45 KW or Steam |

| KER-24000 | 2500x1200x840mm | 3060x1700x1530mm | 2520 L /665.7 Gal | 24.0 KW | 100W,240pcs | 90 KW or Steam |

| >> The ultrasonic generator, cleaning tank and control system are all integrated inone unit, easy to operate. |  |

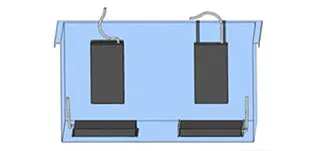

| >> Ultrasonic transducers are placed in transducer packs, which are easily re-placed after end of life. |

>> Transducers packs are uniformly ar-ranged in multi directions of cleaning tank for more homogenous, thoroughly and better cleaning efficiency. |  |

| >> PLC& HMI control system has automatic and manual two working modes. >> Networking function allows remote debug-ging and PLC program update in time. |

>> Fault & maintaining reminding function; >> Emergency stop button is installed. |  |

| >> Equip with circulation and filtration system.Equip w ith oil skimmer and liquid level pro-tector.

|

| >> Electronic components and parts come from world-famous brands. |  |

| >> Lifting device with up-down-shaking movement function makes heavy dirtdrop easily. (Optional) |

lt can be used for different sized metal, plastics, ceramics parts for prewashing, inter-opera-tional washing, or final washing, with the possibility of anti-corrosive protection to removes oil,grease, chips, mud, production slag of the surface of parts.

KEER is an environmental engineering and automation firm providing industrial parts cleaning solutions for a wide range of industrial activities.

We offer our clients comprehensive industrial cleaning solutions, covering the following services: analysis, planning, design, construction, installation, maintenance and supply of related chemical agents for industrial cleaning.

Ever since the inception of our company we have promoted the implementation of the best available technologies, so as to ensure our clients are offered the best solutions for their specific needs.

We own a subsidiary export firm Keer International in providing our international clients with professional consulting and sales service.

Q1: IS THERE ANY DIFFERENCE IN ULTRASONIC CLEANERS?

Ultrasonic cleaners come in 3 categories,

Mini type for cleaning contact lenses, etc. These are very light duty cleaners with small

transducers and very simple generators that are not very efficient.They should never be used for critical cleaning jobs.

The second type are the dental cleaners and small lab size tabletop cleaners, these have a heaver transducer and a better generator and are efficient in cleaning small parts and lab glass.

The third type is the industrial heavy-duty type with very heavy compound transducers and rugged generators that produce high wattage per transducer. These clean more efficiently and can be used for production cleaning. Tanks are heavy-duty welded 304 or 316L stainless steel with overflows and drain ports. Our KR series are this type.

Q2: HOW TO CHOOSE ULTRASONIC FREQUENCY?

Ultrasonic requency is suggested based on cleaning objects'material and pollutants in the objects. Most ultrasonic cleaners operate between 20 and 120 KHz. The system frequency to use depends on the type of cleaning required.

The lower frequencies produce larger cavitation bubbles with more abrasive cleaning.These frequencies are recommended for coarse cleaning needs such as removal of lapping

compounds from durable metal surfaces. For fine cleaning of very delicate items such as jewelry and soft metals with polished surfaces, higher frequency may be more suitable.

Q3: HOW TO CHOOSE A GOOD ULTRASONIC CLEANER?

Frequency: Choose the suitable ultrasonic frequency according to the above suggestions.Inner size of cleaning tank: It should be bigger than cleaning objects' size.

Core element: The core element of an ultrasonic cleaner is ultrasonic transducer. The quality of ultrasonic transducer influences the service life of an ultrasonic cleaner greatly.

Ultrasonic power: The larger the volume of solution, the more ultrasonic power will be needed for cleaning. Most cleaners run at an average power of 50 to 100 watts per gallon, so the larger the tank the more power you need. Simply to say, we can think more power usually indicates faster and more effective cleaning.