Лидер продаж сварочный аппарат с 4 головками и ЧПУ очистительный станок для изготовления окон дверей из

- Категория: Window and Door Making Machine >>>

- Поставщик: Jinan,Glasino,Glass,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 69020.24 $* | 72471.15 $* |

| Aug-18-2025 | 68440.7 $* | 71862.74 $* |

| Jul-18-2025 | 57420.72 $* | 60291.2 $* |

| Jun-18-2025 | 67280.73 $* | 70644.35 $* |

| May-18-2025 | 58580.67 $* | 61509.24 $* |

| Apr-18-2025 | 66120.27 $* | 69426.81 $* |

| Mar-18-2025 | 65540.98 $* | 68817.14 $* |

| Feb-18-2025 | 64960.69 $* | 68208.92 $* |

| Jan-18-2025 | 64380.11 $* | 67599.34 $* |

Характеристики

Product Overview

Hot sale 4 heads CNC welding machine and CNC cleaning machine for uPVC window door making

Glasino automatic welding and cleaning line is used for automatically finish the welding, convey and welding corner cleaning of PVC win-doors rectangular frame or fan.

Features:

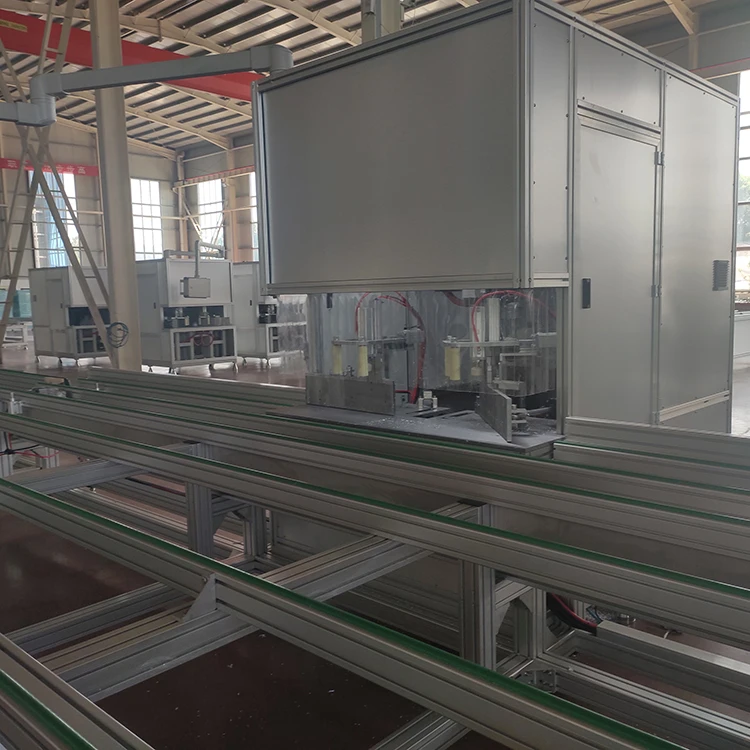

-----This welding-cleaning production line is mainly composed of welding unit, transfer unit, corner cleaning unit and manipulator.

-----This welding-cleaning production line is mainly composed of welding unit, transfer unit, corner cleaning unit and manipulator.

-----Independent research and development of the intelligent corner clearing line, the production line only needs 1 person to operate independently from the rectangular frame (fan) welding, conveying, clearing corners, and automatic palletizing.

-----8-hours output are about 350pcs rectangular frames (fans).

----This production line will saves about 5 people and increases the output more than 3 times

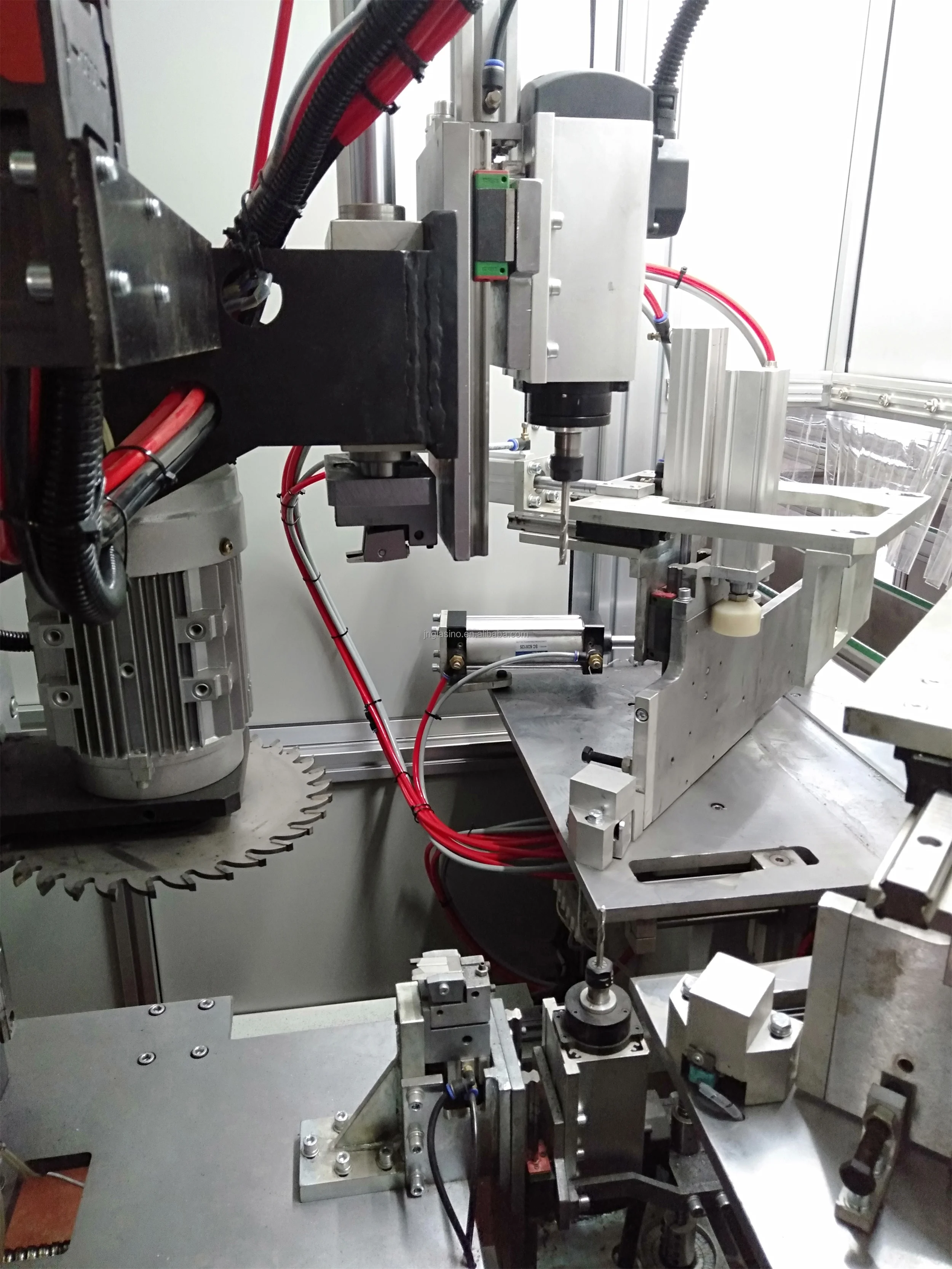

Detail pictures of Machine:

The welding unit adopt horizontal structure arrangement, with square rail kinematic for stable running pair and ball screw shaft transmission and positioning to stable running. It realizes automatic size error compensation, high processing precision and high stability.

Welding line is controlled by industrial computer, equipped with special numerical system independently developed by our company.

The corner cleaning unit is equipped with 5 cutters corner cleaning machine, with high-efficiency servo control system, it can automatically realize the rapid cleaning of almost all welds of plastic door and window welding corners.

Transfer unit: used for automatically conveying the frame or sash after welding.

Automatic frame stacking unit (Manipulator): pneumatic manipulator is used to clamp the rectangular frame, which can quickly and efficiently place the cleaned rectangular frame on the pallet or transport vehicle, saving manpower, reducing labor intensity and improving production efficiency.Technical Parameter

In put power | 380V50HZ |

Total Power | 15KW |

Working pressure | 0.5-0.8Mpa |

Air consumption | 200L/min |

Max. Welding frame | 2600×2200mm |

Min. Welding frame | 650×460mm |

Welding height | 20-120mm |

Welding width | 120mm |

Maximum transmission speed of intermediate section | 30m/min |

Weight | 5200KG |

Overall dimension | About 16000mm×5000mm×2200mm |

Product packaging

Workshop Showing

Exhibition

FAQ

1.Are you a factory or a trading company?

We are factory

2. How long is the equipment warranty?

One year.

3. How to provide after-sales service?

Provide on-site installation, commissioning and training.Free accessories within one year. Provide remote service and video guidance.

4. How long is the delivery time?

10-20days after receive the deposit.

We are factory

2. How long is the equipment warranty?

One year.

3. How to provide after-sales service?

Provide on-site installation, commissioning and training.Free accessories within one year. Provide remote service and video guidance.

4. How long is the delivery time?

10-20days after receive the deposit.

Recommend Products