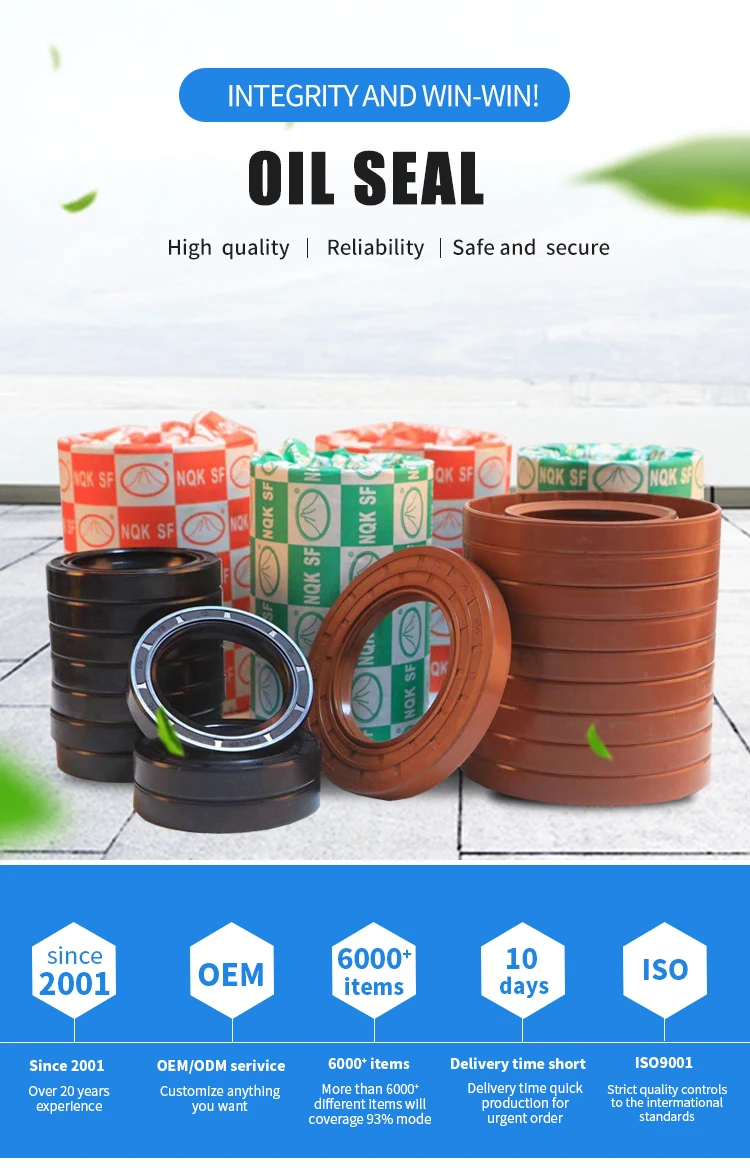

NQKSF высокое качество от производителя резиновое масляное уплотнение TC FKM NBR поворотное для губ

- Категория: Seals >>>

- Поставщик: Xingtai,Shanfeng,Special,Rubber,Product,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.87 $* | 0.15 $* |

| Aug-17-2025 | 0.4 $* | 0.48 $* |

| Jul-17-2025 | 0.14 $* | 0.89 $* |

| Jun-17-2025 | 0.81 $* | 0.40 $* |

| May-17-2025 | 0.87 $* | 0.41 $* |

| Apr-17-2025 | 0.57 $* | 0.86 $* |

| Mar-17-2025 | 0.42 $* | 0.47 $* |

| Feb-17-2025 | 0.22 $* | 0.41 $* |

| Jan-17-2025 | 0.86 $* | 0.19 $* |

Характеристики

Product Description

Main Products: TC Oil Seals& rubber oil seal

Application: Industry, motorcycle, automobile, machines,truck, tractors, valves, etc.

Material : NBR, FKM, SILICONE, EPDM,SBR,SR,CR, HNBR,etc.

Color: Black, red, brown,blue, green, and so on.

Stocklist: More than 6000 items TC NBR FKM rubber oil seal in stock

Material : NBR, FKM, SILICONE, EPDM,SBR,SR,CR, HNBR,etc.

Color: Black, red, brown,blue, green, and so on.

Stocklist: More than 6000 items TC NBR FKM rubber oil seal in stock

MATERIAL | TEMP | ADANTAGES | LIMITATION |

Nitrile Rubbrt (NBR) | -40~125℃ | ■Good oil and fuel resistance■High tensile strength ■Low swelling in water | ■Poor weather and ozine resistance■Poor resistance against polar lkuids ■Poor resistance against clhydrocarbon ■Poor resistance against aromatic fluids |

Fluorinated Rubber (FKM) | -20~250℃ | ■The resistance against oil and fuels is better than other types■The only highly elastic rubber whice is resistance to aromatci and chlornated hydrocarbons ■Exccllcent hcat resistance ■Exccllcent weather and ozonc resistance ■Exccllcent acid resistance ■Low swelling in water | ■Limited cold flexibliity■Limited tensile and tear strength ■Limited wear resistance ■High compression set in hot water ■Poor resistance to polaric solvents |

Polyacrylate Rubber (ACM) | -25~150℃ | ■Good oil and fuels resistance■Good weater and ozone resistance | ■Not usable in contact with water and water solutions ■Limited cold flexibility ■Limited tensile strength and tear resistance ■Poor wear reisistance ■Poor resistance against polar and aromatic and chlorinared hydrocarhons |

Silicone Rubber (VQM) | -60~225℃ | ■Best heat resistance of all rubber types ■Excellent low temp resistance of all rubber types ■Excellent weather and ozone resistance | ■Poor tensile and tear strength ■Poor wear resistance ■Sensitive to hydrolysis ■Poor resistance against aromatic oils and oxidized mineral oils ■Poor diffusion resistance |

Production Pictures

Company Profile

Certifications

FAQ

Q1. What is the payment term?

A: We accept a T/T 30% deposit and a 70% balance of a current bill of lading or a letter of credit.

Q2. What is the normal delivery time for product orders?

Q2. What is the normal delivery time for product orders?

A: The average delivery time of the sample is 1-2 weeks. If the mold production is involved, the delivery cycle of the production mold is 10 days, and the average production time after the sample is approved is 1-2 weeks.

Q3. What is your standard packaging?

A: All goods will be packed in PE bags and then packed in cartons and

filled with trays. Special packaging methods are accepted when needed, but charges may apply.

filled with trays. Special packaging methods are accepted when needed, but charges may apply.

Q4: How to check the quality of bulk orders?

A1: Our inspection procedures include, first inspection/patrol inspection/initial inspection/full inspection/shipment inspection.

A2: We provide quality certification to customers before delivery, such as measurement reports, material data sheets, etc.

A3: We accept third party inspections such as SGS, TUV, INTERTEK, BV, etc.

Q5: How do I choose a raw compound for my application?

A: With years of experience in using a variety of materials, we can help you choose the material that best suits your needs, keeping in mind the cost of materials.

Q6: Can you provide materials of different colors?

A: Yes, we can produce custom molded rubber and silicone

rubber products in different colors. Color codes are required when ordering.

rubber products in different colors. Color codes are required when ordering.

Q7: From which side can you produce which materials?

A: NBR, EPDM, silicone, FKM, NEOPRENE (CR), NR, IIR, SBR, ACM, AEM, fluorosilicon (FVMQ), FFKM, liquid silica gel, and the like.

A: NBR, EPDM, silicone, FKM, NEOPRENE (CR), NR, IIR, SBR, ACM, AEM, fluorosilicon (FVMQ), FFKM, liquid silica gel, and the like.

Похожие товары

Уплотнительное кольцо DLSEALS FEP и PTFE

US $0.06-$0.69

Масляное уплотнение GLY50 размер 50x60x6 мм

US $4.69-$5.94