T-126-3-3 дерево расточными сверлильный станок с ЧПУ для двери высверливания и от Шунде Гуандун Китай

- Категория: Wood Boring Machines >>>

- Поставщик: Foshan,Shunde,Ruinuo,CNC,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 35700.49 $* | 37485.33 $* |

| Aug-15-2025 | 35400.6 $* | 37170.97 $* |

| Jul-15-2025 | 29700.65 $* | 31185.20 $* |

| Jun-15-2025 | 34800.78 $* | 36540.9 $* |

| May-15-2025 | 30300.32 $* | 31815.79 $* |

| Apr-15-2025 | 34200.82 $* | 35910.66 $* |

| Mar-15-2025 | 33900.72 $* | 35595.42 $* |

| Feb-15-2025 | 33600.94 $* | 35280.75 $* |

| Jan-15-2025 | 33300.94 $* | 34965.47 $* |

Характеристики

Product name | T-126-3-3 double-sided machining center for door |

Working effciency | 80-100 pcs/ Hours |

Working length | 200-2800mm |

Working width | 50-1200mm |

Working thickness | 12-40mm |

X(A)/Y/Z max working speed | 120/80/30m/min |

Spindle | Top spindle 6kW*3,Bottom spindle 6kW*3 |

Spindle speed | 18000rpm |

Top: 6kW*3,bottom:6kW*3 | |

Drilling magazine speed | Top: 2800r/min, bottom: 2840r/min |

Top drilling (vertical head) | V12*2 pcs |

Top drilling (Horizontal head) | X: (2*2 pcs+ Y: 2*2 )*2pcs |

Bottom drilling (vertical head) | V10 pcs |

Drill pipe delay protection | Horizontal drilling action, Vertical drilling delay |

Drilling depth protection | Yes(by software) |

Drilling unit | 2 |

Bottom dust-blowing device | Yes |

Voltage | 380V/3Phase/50Hz |

Total power | 20kw |

Overall size | L*W*H 5300×2580×2150mm (square:16.25㎡) |

Moniter | Industrial Main Board |

Code scanner | manual |

AC contactor | France |

Sensor | Otto nix/Korea |

Low voltage electrical switches | Schneider /France |

pneumatic component | EMC |

Drilling magazine | KMS/China |

Servo motor | TaiWan syntec |

Reducer box | R-TUP planetary gear |

Control systerm | Syntec control systerm/TaiWan |

Inverter | Sunfar/China |

Guide rail | Roust/Germany |

Ball screw | TBI/TaiWan |

pinion and rack | Grinding grade/home made |

Pump | 2.2kW/Dry type |

Operation COM systerm | Syntec+R-TUP Independent R&D on the microcomputer |

Windows | Windows7 32bit |

Available file format | mpr、BAN、XML,(can drawing in the systerm and transfer the program) |

Gripper self-cleaning | yes |

Bottom dust-blowing device | yes |

Manipulator grasping and positioning | Support pre- position |

Two sides grooving | First top, last bottom |

Measure the board size | Plate size pre-detection, avoid the wrong processing, sound and photoelectric prompt |

Process hole | principle of proximity |

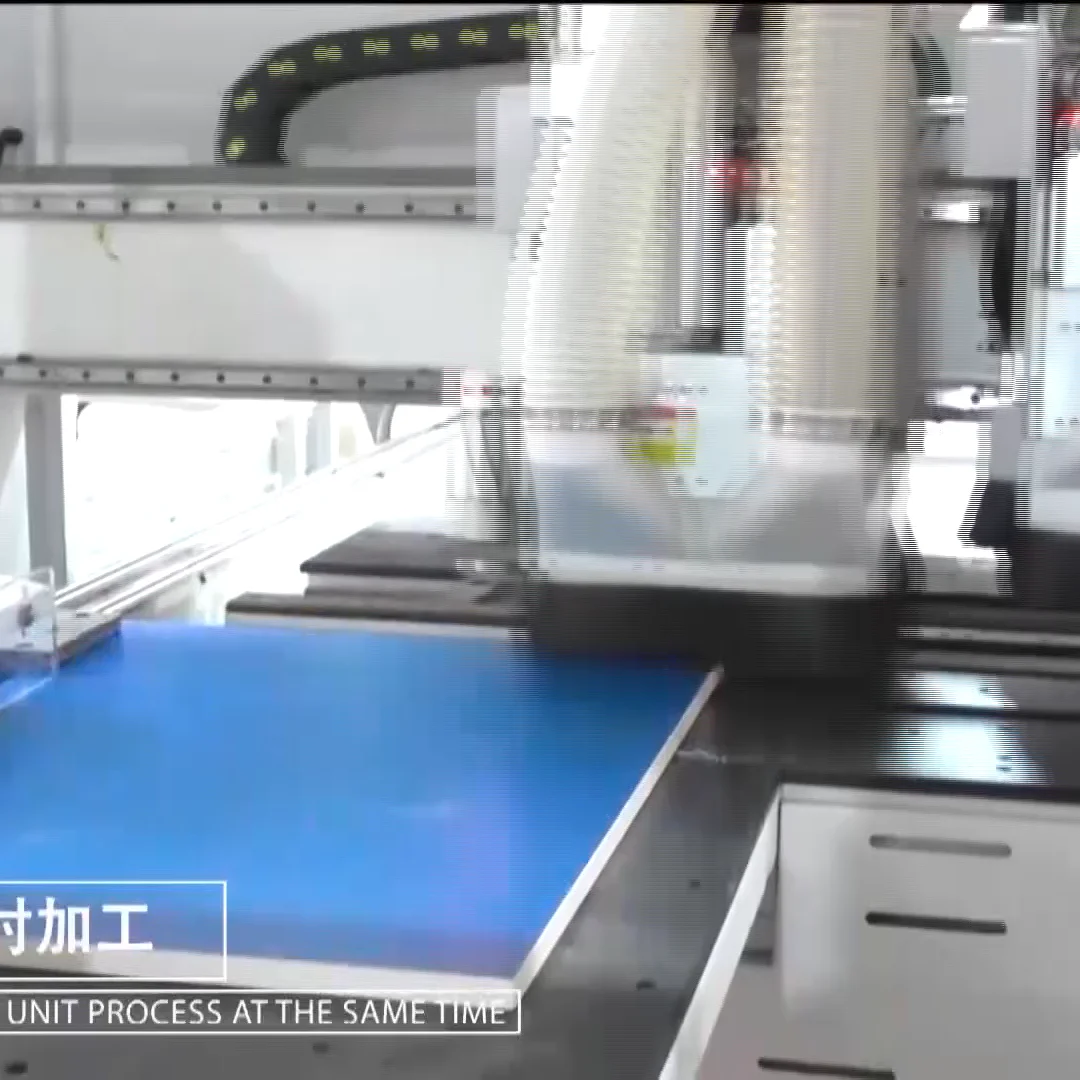

Features | Can process 6 sides work at one time |

Rectangular steel structure, strong and durable | |

Standard manual loading and unloading of front and rear ends | |

Manual scaner gun | |

Double clamp | |

X/Y rack gear transmission ,Zaxis ball screw transmission | |

Servo control | |

Moving bracket + floating platform directly improves drilling efficiency and accuracy |

1.Quickly and accurately,can drill multi kinds of hole and there is no limit to the board width

definite signs, very clear line connections with a circuit

diagram, once any breakdown, will be very easy to check

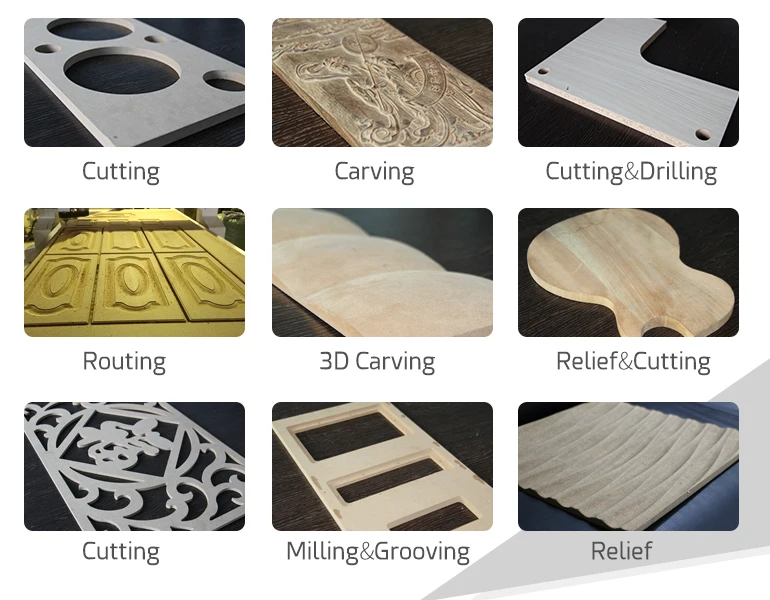

1. What kinds of processing can the CNC router do?

A: The CNC Router can be used in cutting, milling, grinding, planning, drilling, engraving etc., especially for

abnormal shape's cutting.

2.What kinds of materials can the CNC router work on?

A: It can work on a lot of different materials besides kinds of wooden materials, such as acryl,

light guide, diffusion board, PVC, ABS PF, PE, PU, Fiber glass, man-made stone, compact grade

laminate board, Bakelite, aluminum profile, cooper plates etc.. For different materials, we have corresponding machines for choices.

3.Guarantee & After-sale Service

A..12 Months warranty under normal use and lifelong maintenance we supply

B..24 hours technical support by phone, email and other online contact.

C..Free training on machine operation, daily maintenance etc. in seller's factory.

D..We can send engineer go to overseas training

4.Delivery Time

Usually, for normal model, within 15 -20 days after get the deposit

5. Payment Terms

A.T/T in advance

B.L/C is allowed if the amount is big. Please issue the L/C draft for our configuration first.

C.Other kinds of payment we can consider if acceptable for us

Dear, in order to recommend the best suitable machine with the best quality and price for you, please kindly contact me with below questions, our professional services will satisfy you!

1. what is you product?

2. what is the material of you product, and the size( length/width/thickness)?

3. what do you want to do on your product, cutting, drilling, milling, evgraving etc.?

4.what is the working area do you want?

5. do you have any other technical requirements? the more the better.

if you can provide some pictures of your products,that would be great!

Welcome to visit our factory, we can arrange pickup. our factory is located in Lunjiao town, Shunde District Foshan City,

1 hour drive from Guangzhou airport

30 minutes drive from Lecong international furniture town

20 minutes drive from Leliu furniture hardware town

40 minutes drive from Foshan building material town