QMB525D-H однобоковая деревообрабатывающая строгальная машина толщина промышленного деревянного плантатора и

- Категория: Wood Planer >>>

- Поставщик: Huzhou,Qingcheng,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 11543.95 $* | 12120.19 $* |

| Aug-19-2025 | 11446.55 $* | 12018.15 $* |

| Jul-19-2025 | 9603.70 $* | 10083.2 $* |

| Jun-19-2025 | 11252.96 $* | 11815.21 $* |

| May-19-2025 | 9797.36 $* | 10287.53 $* |

| Apr-19-2025 | 11058.64 $* | 11611.51 $* |

| Mar-19-2025 | 10961.36 $* | 11509.23 $* |

| Feb-19-2025 | 10864.78 $* | 11407.70 $* |

| Jan-19-2025 | 10767.18 $* | 11305.97 $* |

Характеристики

QCM QMB525D-H Single Side Woodworking Planer Thickness Industrial Wood Planner And Thicknesser

Product Description

QCM Smart Panther Woodworking Machinery Wood Thicknessing Machine Heavy Type Single-side Planer Thicknesser | ||||||

Technical Parameter | ||||||

Specifications | Unit | MBZ106D/D-H | QMB525D-H | |||

Working width | mm | 630 | 500 | |||

Working thickness | mm | 3-300 | 10-170 | |||

Min.working length | mm | 300 | 245 | |||

Max cutting depth (Upper/Bottom) | mm | 8 | 5/0.8 | |||

Feeding speed | m/min | 5-18 | 6-30 | |||

Spindle speed | r/min | 5000 | 5800 | |||

Spindle cutting dia. | mm | 125 | 101 | |||

Total power | kW/HP | 9.37/12.5 | 14.5/19 | |||

Spindle motor | kW/HP | 7.5/10 | / | |||

Front blade spindle motor | kW/HP | / | 5.5/7.5 | |||

Back blade spindle motor | kW/HP | / | 4/5.5 | |||

Feeding motor | kW/HP | 1.5/2 | 2.2/3 | |||

Lifting motor | kW/HP | 0.37/0.5 | 0.75/1 | |||

Suction hood dia. | mm | 2*150 | 4*120 | |||

Overall dimensions | mm | 1150*1300*1520 | 2260*1030*1600 | |||

Weight | kg | 1250 | 2250 | |||

Our Advantages

Product Main Features

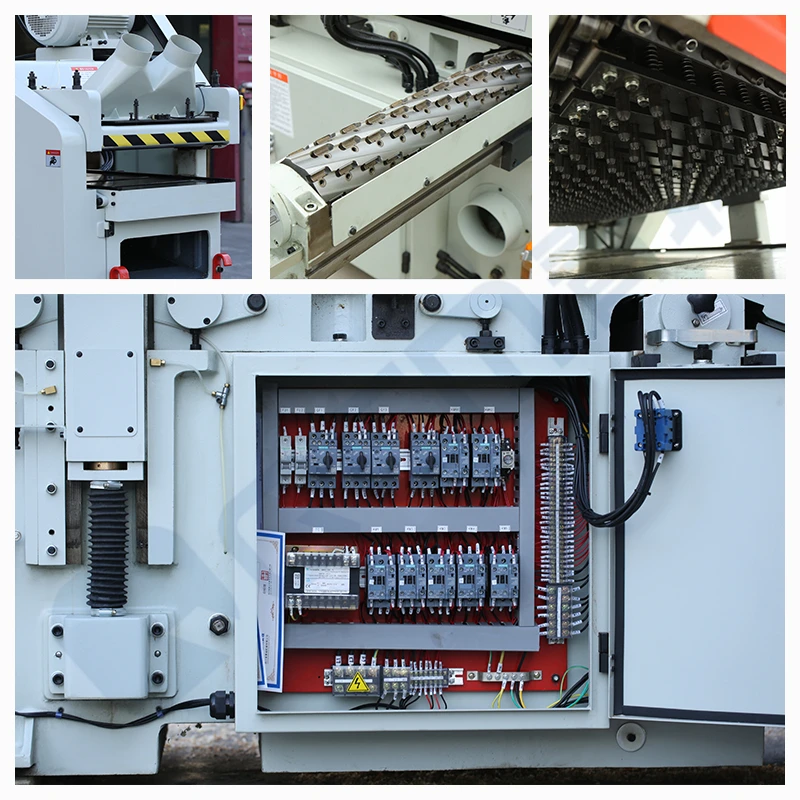

1. This machine adopts integral casting body with stable performance, good precision and good rigidity.

2. The entire Cast Iron – Chromed In-feed table is normalization heat treated for maximum stability. In-feed Table & Fence adjustment is quickly accomplished by means of a quick-setting levers.

3. The upper and bottom cutter head are equipped with imported heavy-cutting spiral cutter, which have been dynamically balanced and equipped with ternational brand SKF bearings for precision assembly, with stable performance, good accuracy and good durability.

4. The pressure spikes are in an overlapped layout with a minimum of gaps that hold the workpiece firmly and evening ensuring shake-free feeding, even for short workpiece.

5. The thickness of cut can be controlled by a digital positioning control. Once the preset position is reached, the table elevation stops automatically.

6. The automatic lubricator delivers frequent lubrication oil to the caterpillar chain.

7. Reduce wear caused by temperature rise and improve efficiency of power transmission.

8. Siemens and Schneider electrical products and appliances insure the whole machine run well with a stable performance.

2. The entire Cast Iron – Chromed In-feed table is normalization heat treated for maximum stability. In-feed Table & Fence adjustment is quickly accomplished by means of a quick-setting levers.

3. The upper and bottom cutter head are equipped with imported heavy-cutting spiral cutter, which have been dynamically balanced and equipped with ternational brand SKF bearings for precision assembly, with stable performance, good accuracy and good durability.

4. The pressure spikes are in an overlapped layout with a minimum of gaps that hold the workpiece firmly and evening ensuring shake-free feeding, even for short workpiece.

5. The thickness of cut can be controlled by a digital positioning control. Once the preset position is reached, the table elevation stops automatically.

6. The automatic lubricator delivers frequent lubrication oil to the caterpillar chain.

7. Reduce wear caused by temperature rise and improve efficiency of power transmission.

8. Siemens and Schneider electrical products and appliances insure the whole machine run well with a stable performance.

Related Products

Company Information

Certificate & Delivery

HUZHOU QINGCHENG MACHINERY CO., LTD

QCM Machinery was established in 1970 and have been specializing in production of woodworking machinery for more than 50 years now.

We have our own casting workshop and more than 300 sets of modern CNC machining equipment and testing equipment. Strong R&D team with 55 people can provide our customers with the biggest professional technical support.

Choose our machinery, to help you improve productivity, processing quality, and profit.

FAQ

1. Manufacturer or Trading company?

QCM (Qingcheng Machinery) is a professional manufacturer of woodworking machinery since 1970. With more than 50 years experience, we have developed to be the top and most powerful manufacturer of woodworking machinery in China.

2. Payment Term?

TT , 50% advance payment and 50% balance before delivery.

3. Lead Time?

Within 15 days for regular stock machine after receiving advance payment.

45-60 days for customized machines.

4. Warranty ?

QCM (Qingcheng Machinery) is a professional manufacturer of woodworking machinery since 1970. With more than 50 years experience, we have developed to be the top and most powerful manufacturer of woodworking machinery in China.

2. Payment Term?

TT , 50% advance payment and 50% balance before delivery.

3. Lead Time?

Within 15 days for regular stock machine after receiving advance payment.

45-60 days for customized machines.

4. Warranty ?

3 years for machine, 3 years for the core components.

5. Spare Parts?

Unified standards spare parts are available anytime. It will not be a problem if you want to replace spare parts of the machine you bought anytime.

6. Pre-sale Service?

As a leader in woodworking machinery field for more than 50 years, professional and efficient proposals can be provided anytime. Our strong R&D team with more than 50 persons are also your team.

7. After-sale Service?

Professional after-sales service team, 24 hours technical support by email, call and video.

If remote support is not workable, our engineer is available to visit at your expenses of accommodation and round tickets.

5. Spare Parts?

Unified standards spare parts are available anytime. It will not be a problem if you want to replace spare parts of the machine you bought anytime.

6. Pre-sale Service?

As a leader in woodworking machinery field for more than 50 years, professional and efficient proposals can be provided anytime. Our strong R&D team with more than 50 persons are also your team.

7. After-sale Service?

Professional after-sales service team, 24 hours technical support by email, call and video.

If remote support is not workable, our engineer is available to visit at your expenses of accommodation and round tickets.

8. Why us?

1). 50 years experience in wood working machinery since 1970.

2). Our own casting workshop to insure extra heavy one-piece cast iron machine body for maximum stability and rigidity by standard configuration.

3). All spindles are precision constructed and specially heat treated to provide maximum cutting stability and permanent accuracy. Spindle is processed in constant temperature workshop to insure high precision and stability, +-0.1mm high accuracy.

1). 50 years experience in wood working machinery since 1970.

2). Our own casting workshop to insure extra heavy one-piece cast iron machine body for maximum stability and rigidity by standard configuration.

3). All spindles are precision constructed and specially heat treated to provide maximum cutting stability and permanent accuracy. Spindle is processed in constant temperature workshop to insure high precision and stability, +-0.1mm high accuracy.

4). Warranty: 3 years for machine, 3 years for the core3 years for machine, 3 years for the core components.

QCM QMB525D-H Single Side Woodworking Planer Thickness Industrial Wood Planner And Thicknesser

Похожие товары

Штанга из чугуна с винтовой головкой, 6 дюймов

US $100.00-$259.00

Chinese Best Selling Industrial Furniture Tools Woodworking surface planer

US $464.00-$511.00