Автоматическая машина для разделения риса MGCZ100 46

- Категория: Rice Mill >>>

- Поставщик: Guangzhou,Fengtai,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 1190.96 $* | 1250.57 $* |

| Aug-18-2025 | 1180.38 $* | 1239.80 $* |

| Jul-18-2025 | 990.25 $* | 1040.70 $* |

| Jun-18-2025 | 1160.88 $* | 1218.14 $* |

| May-18-2025 | 1010.49 $* | 1061.10 $* |

| Apr-18-2025 | 1140.17 $* | 1197.39 $* |

| Mar-18-2025 | 1130.17 $* | 1187.37 $* |

| Feb-18-2025 | 1120.40 $* | 1176.20 $* |

| Jan-18-2025 | 1110.1 $* | 1166.98 $* |

Характеристики

Function:

This series of Paddy separator is an ideal equipment designed for separating the brown rice and the paddy that is not be husked. The principle is that the paddy and the brown rice have a different bulk densities, with the reciprocating movement of sieves, they are separated. This series of gravity paddy separator can improve the the whole rice output rate greatly in the full line of rice processing line. So it can improve the economic benefit enormously.

Features:

Compact structure, easy to be operated;

Good applicability for both long shape grain rice and round shape grain rice;

Low mechanical barycenter, good balance, reasonable rotation speed, stable processing properly.

| Model | Clean husked rice (t/h) | Spacer plate | Spacer plate setting angle Vertical(°) Horizontal(°) | Main shaft rotation Speed (rpm) | Power | Overall dimension L*W*H(mm) | |

| MGCZ100*4 | 1-1.3 | 4 | 6-6.5 | 14-18 | ≥258 | 1.1-1.5 | 1250*1760*1376 |

| MGCZ100*5 | 1.3-2 | 5 | 6-6.5 | 14-18 | ≥258 | 1.1-1.5 | 1250*1760*1416 |

| MGCZ100*6 | 1.7-2.1 | 6 | 6-6.5 | 14-18 | ≥258 | 1.1-1.5 | 1250*1760*1456 |

| MGCZ100*7 | 2.1-2.3 | 7 | 6-6.5 | 14-18 | ≥258 | 1.1-1.5 | 1250*1760*1496 |

| MGCZ100*10 | 2.6-3.5 | 10 | 6-6.5 | 14-18 | ≥254 | 1.5 | 1250*1760*1625 |

| MGCZ100*12 | 3-4 | 12 | 6-6.5 | 14-18 | ≥254 | 1.5 | 1250*1760*1660 |

| MGCZ100*16 | 3.5-4.5 | 16 | 6-6.5 | 14-18 | ≥254 | 2.2 | 1250*1760*1845 |

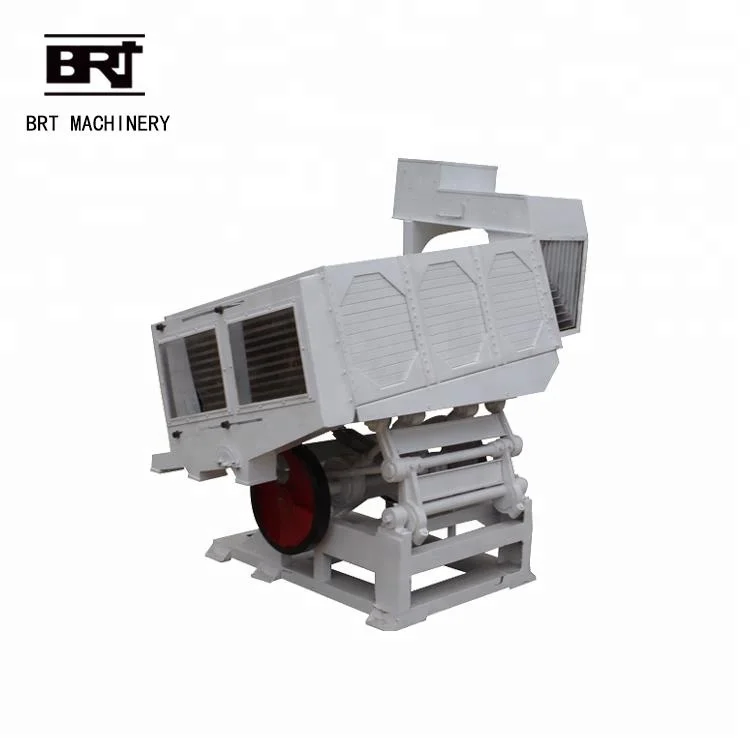

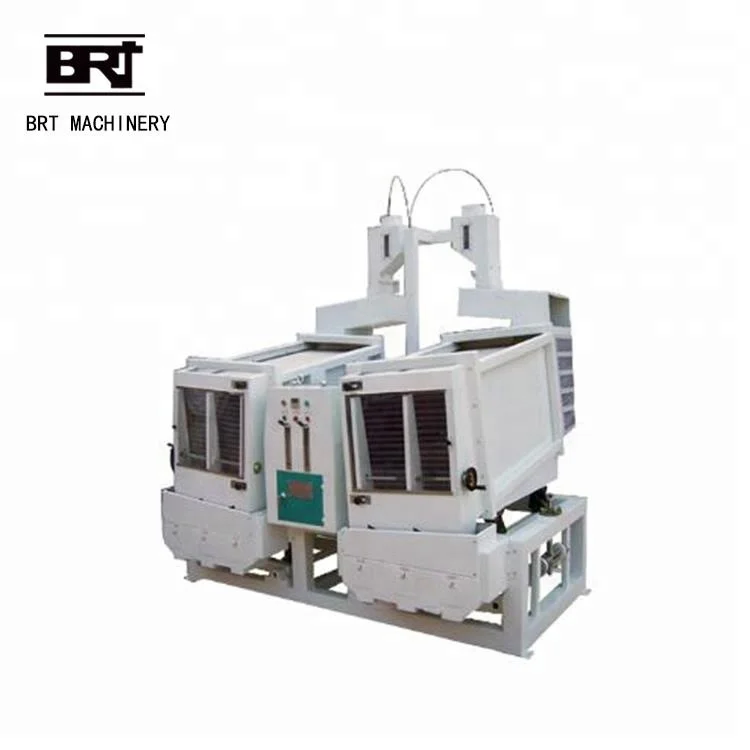

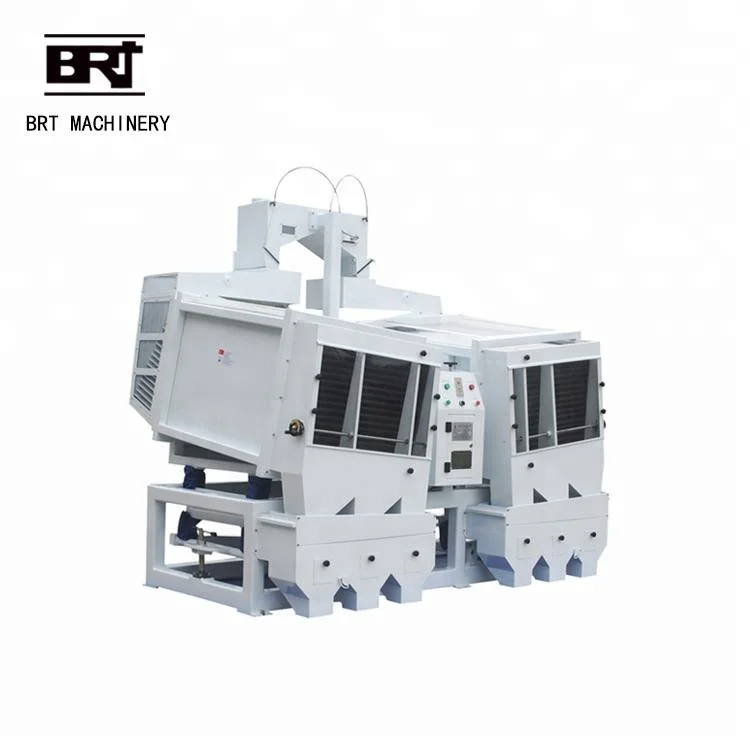

General structure for Automatic paddy separating machine gravity MGCZ100 rice paddy separating machinery 46 rice paddy separator

General structure for Automatic paddy separating machine gravity MGCZ100 rice paddy separating machinery 46 rice paddy separator2. Separating box body: the separating disc is fixed inside grading frame, which is formed in a integer and act as sinus movement; the grading plate and turn plate are placed in discharge chute, which can control flexibly and easily the separating quality.

3. Eccentric drive device: drafting block is connected with separating box, the bearing pedestal is connected with machine base, which make the separating box body act as sinus movement in virtue of power of motor.

4. Support bar device: there are rolling bearing above and under support bar for supporting and positioning and positioning the separating box body to make the separating box body run stably. The elevating mechanism in the device can

5. Machine base: it is formed as a integer by profiled bar welding, and it is safe.

Pre-sale:

Product selection: Supply professional drawing and lists

Win-win cooperation: 1. Sign the contract 2. Establish mutual benefit, stratege.

In-sale:

Design evaluation: Design of process and equipment layout, electric power suggestion.

Installation: 1. Quality and quantity guaranteed 2. Completion of hand over

Acceptance: Acceptance test

Technical training: 1.On-site installation and products training

2. Operation skills training 3.Maintenance training 4. Centralized technical training.

After-sale:

Technical service: Long time technical service

Master device: Free supply during warranty period.

Accessories supplying: Supplying spare parts with cost.

Guangzhou Fengtai Machinery Co., Ltd. is an enterprise that specialized in grain and oil processing equipment manufacturing, engineering designing, installation and selling service.

1. With more than 20 years experiences.

2. Capacity to produce 2000 sets of varied rice milling.

3. Professional pre-sales & after-sales team to guarrantee the best satisfaction.

4. Skillfull engineering team for R&D persuiting the best performance of each machinery

Q1.What’s your advantage? Why we choose you?

A: 20 Years experience of design and manufacture grain machinery.We have the most professional techniques and team. Big advantage in price.

Q2.What’s the Payment?

A:T/T would be better with quick transfer and few bank fees. L/C could also be accept, but the procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4: Can you show how the machine works?

A: Certainly, we will send you the Operating video & instruction to you together with machines, to help you use the machines better.

Q5: How can I know your machine works well?

A: Before delivery, we will test and adjust the machine working condition for you, then you can use directly when you get it.