Стабильная производительность машина для производства пеллет биомассы из

- Категория: Biomass Briquette Machines >>>

- Поставщик: Henan,Qimai,Mechanical,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.68 $* | 0.24 $* |

| Aug-15-2025 | 0.28 $* | 0.55 $* |

| Jul-15-2025 | 0.80 $* | 0.1 $* |

| Jun-15-2025 | 0.69 $* | 0.77 $* |

| May-15-2025 | 0.52 $* | 0.74 $* |

| Apr-15-2025 | 0.29 $* | 0.22 $* |

| Mar-15-2025 | 0.8 $* | 0.85 $* |

| Feb-15-2025 | 0.88 $* | 0.33 $* |

| Jan-15-2025 | 0.9 $* | 0.7 $* |

Характеристики

Stable Performance biomass pellet machine from rice

1.Raw materials of pellet machine wood pellet mill

There are many raw materials for pellets, such as wood, paper, cardboard, grain, alfalfa, rice husk and straw, sawdust, shavings, cow manure, chicken manure, grass clippings, yard waste, forest and agricultural waste.

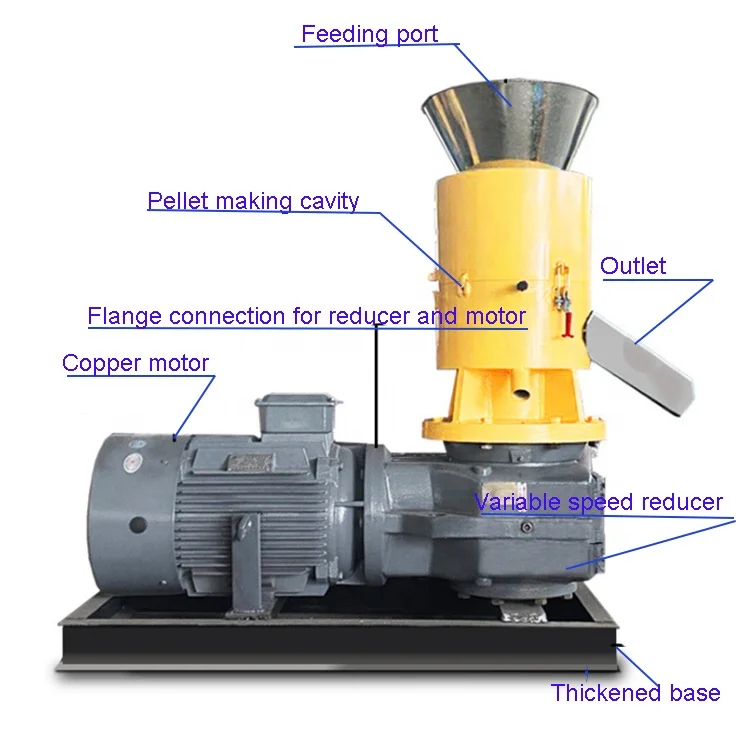

2.Featurs of wood pellet mill

1. Pellet machine Wood pellet machine is a kind of bio-fuel forming machinery used in fireplaces, heating systems, hotels, restaurants, bathrooms, boilers, biomass power plants, etc.

2. It adopts high-precision cylindrical inner worm gear helical gear transmission, the transmission efficiency is as high as 98%.

3. The main body of the machine is made of high-quality refined steel with uniform thickness and compact structure.

4. The bearing is a high-precision bearing, and the oil seal is high temperature resistant and durable.

5. The automatic lubricating oil return system can automatically replenish oil in time.

6. The mold is a double-sided mold, using high-strength alloy steel, and the mold has a long service life.

7. The size of the final pellet can be customized according to customer requirements, the pellet diameter is 4-12MM. The density of the pellet can be 6.9 g/cm3, and the heat release is 3500-5500 calories.

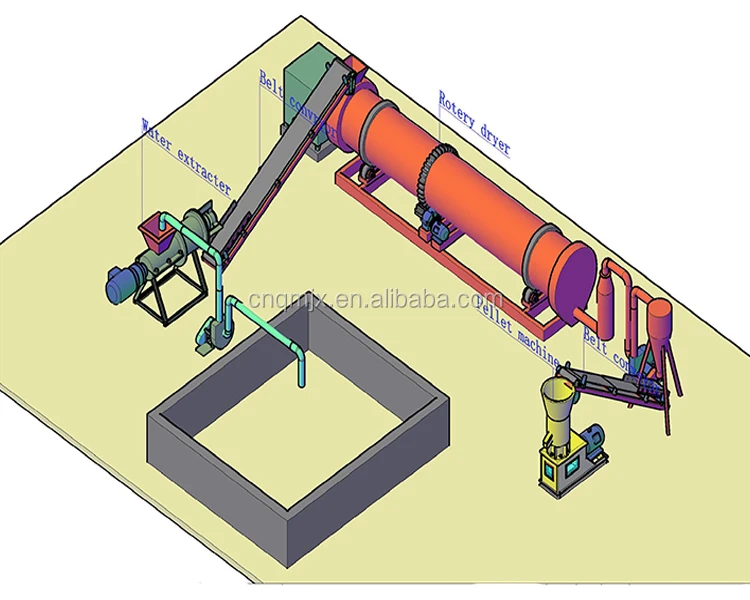

3.Workflow for wood pellet mill

(A) Use of biomass pellets

Biomass pellets are widely used in industries such as industrial boilers, home fireplaces and biomass power generation. Biomass pellets are gradually replacing industrial fuels, such as electricity, oil, natural gas, and coal.

(B) Grinding process

Before the raw meal is made into biomass pellets, the raw material is first crushed. The hammer mill is used to further crush these small fragments to 4-6 mm particles.

(C) Drying process

After crushing the raw materials, a dryer is needed because most raw wood has a moisture content of about 40%. But the best raw material for pellets has a moisture content of 13%-15%. Therefore, the raw materials must be dried in a dryer. After crushing and drying, you can start making wood pellets.

(D) Granulation process

After the raw materials are properly crushed and dried, they can be used in the granulator. The pelletizer is the key to the entire process. Take care to avoid mixing metal or stone in the raw materials to avoid damage to the mold and roller of the pelletizer.

(E) Cooling and screening process

Usually after granulation, the temperature of granulation is between 60-80 degrees, and the moisture content is close to 15%. For storage, fans must be used to reduce the surface temperature and moisture content.

(F) Packaging

Wood pellets need to be stored and transported to consumers. The pellets must be stored away from moisture, sealed and packed with airtight plastic bags. the packing process. In order to protect the wood pellets becoming getting

4.Parameters of wood pellet mill

Type |

Capacity(KG/h) |

Power(kw) |

Production Specification(mm) |

Weight(KG) |

Dimension(mm) |

QM-250 |

150-200 |

15 |

Φ4-12 |

500 |

1200*800*500 |

QM-300 |

200-300 |

22 |

Φ4-12 |

650 |

1300*1200*600 |

QM-350 |

300-400 |

30 |

Φ4-12 |

800 |

1500*1300*700 |

QM-450 |

500-600 |

37 |

Φ4-12 |

1200 |

1800*1500*850 |

QM-550 |

700-800 |

45 |

Φ4-12 |

1500 |

2300*1600*1000 |

QM-800 |

1500-2000 |

90 |

Φ4-30 |

2000 |

2800*2350*1350 |

5.Source Factory

After-sales service

Qimai can provide turkey service for customers, such as engineering consultation, engineering design, equipment manufacturing, packing & transportation, installation & commissioning personnel training etc.

About Spare Parts

About Training

Qimai machinery could offer excellent facilities and comfortable environment and training services to different customers. The training should include product training, safety training, operation training, maintenance know-how, technical know-how training, and regulations training, etc. All of the training is customized to fulfill every customer’s expectations. Training programs can be conducted in our workshop, or at customer’s site.

About Installation and Commissioning

Qimai is able to guide the overall installation of whole set production line, including crushing production line and cement equipment production line, etc., which will allow you to start the normal operation of equipment immediately. After installation,we will make inspection of the whole machine commissioning and operation condition and provide you testing data report of installation.