Сортировочная машина для взвешивания посылок и складская логистика 4*6 рядов по индивидуальному

- Категория: Грузовое и складское оборудование >>>

- Поставщик: Senad,Robot(Shanghai)Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.92 $* | 0.60 $* |

| Aug-18-2025 | 0.40 $* | 0.93 $* |

| Jul-18-2025 | 0.91 $* | 0.20 $* |

| Jun-18-2025 | 0.83 $* | 0.25 $* |

| May-18-2025 | 0.45 $* | 0.98 $* |

| Apr-18-2025 | 0.62 $* | 0.44 $* |

| Mar-18-2025 | 0.23 $* | 0.74 $* |

| Feb-18-2025 | 0.62 $* | 0.19 $* |

| Jan-18-2025 | 0.7 $* | 0.35 $* |

Характеристики

Product Description

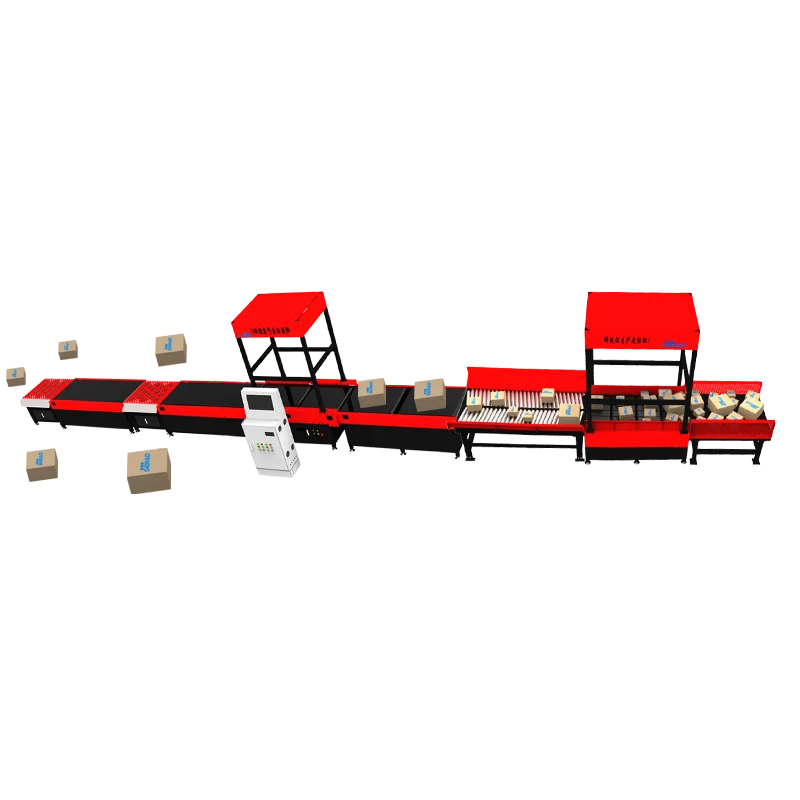

Parcel singulating sorting DWS system machine for automated logistics warehousing solution

This is a multiple functioned automated warehouse solution. It covers the majority sections that a large logistics warehouses have to do.

This is a multiple functioned automated warehouse solution. It covers the majority sections that a large logistics warehouses have to do.

At the pressure of fast increasing logistics output, deliver-on-time becomes a major competition factor to capture the proportion of the market.

Senad successfully integrated parcel singulating system, in-motion dimensioning weighing scanning (DWS) system, and parcel sorting machine lines,

Reducing 60% of the labor cost

Improving 80% of the output.

Largely increased the warehousing efficiency and accelerated the transportation delivery.

Now it's popular among the leading Courier Epxress Parcel and Ecommerce companies.

Features

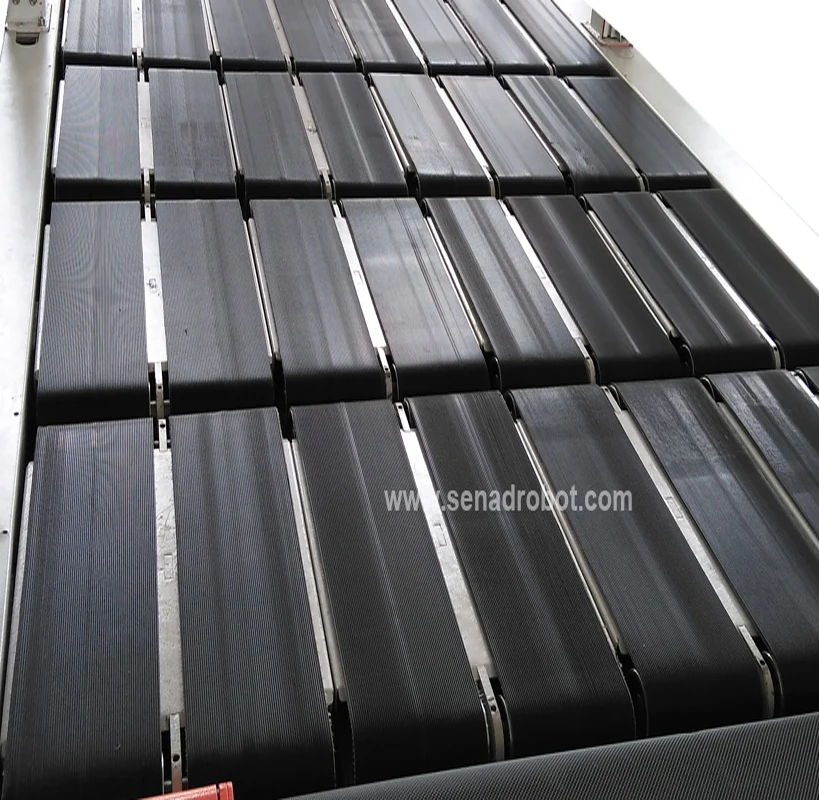

1. Parcel singulating system, separate conveying mess parcels in seconds

Parcel singulating system is developed by the joint application of deep learning intelligent camera and 3D area-array camera.

With the deep learning algorithms and 3D process technologies, the system at real time positions the parcels exactly. And with the intelligent controlling system, the system controls the modular belt conveyors to convey each parcel one by one in order with a certain gap.

Then it is followed by a centralized roller conveyor. The parcels are then conveyed to the middle gradually.

After the centralized roller conveyor, the parcels come to an in-motion Dimensioning Weighing Scanning conveyor machine.

Parcel positioning

Parcel singulating

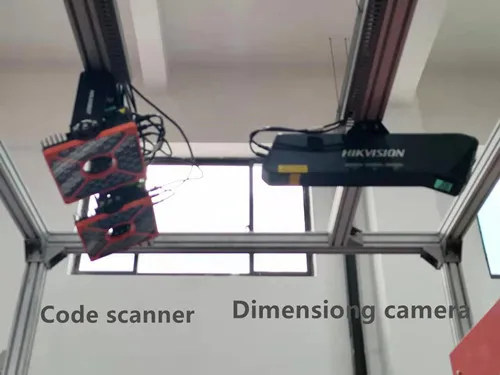

2. Dimension Weigh Scan (DWS) system conveyor machine, acquiring ship information in a second

The Dimension Weigh Scan (DWS) system conveyor machine contains three parts: parcel accelerating conveyor, dimensioning weighing scanning conveyor and information treatment conveyor.

Each section has its functions. Parcel gap is widened so that only one parcel will be passed to the dimensioning weighing scanning conveyor. The dimensioning weighing scanning stage have more features.

DWS Advantages:

a. High performance code reading system

Item | Description |

Reading rate | Up to 99.9% |

Reading time | <1s |

Overcome special code conditions | Low code, dirty code, polyfilm code,vague code,deformed code... |

Readable codes | 1D code: Code 128, Cod 39, Code 93, Codabar, EAN, ITF25,UPC-A |

2D code: DM(DPM),QR |

b. High sensitive weight sensor

Dynamic weighing

Use high precision dynamic weighing sensors

Durable in use

The equipment will intelligently control and make sure weigh only one package at one time.

c. High accuracy L*W*H dimension measuring

Intelligent measure dimensions

Linear structure light

Size accuracy ±10mm for standard parcels, ±15mm for non-standard parcels

Suggested load capacity 0.04~60kg

Weighing accuracy ±20g

d. Various packages processed

Including irregular shaped packages

* Regular Cartons

* Soft packages

* Sacks

* Irregular packages

3. Parcel sorting system, deliver parcels to the right exit ports

Sorting machine can be mated with belt conveyors. When one ordered our integrated sorting line, he will receive the machines in several small entire parts. Only move all the small parts in order and joint them with numbered wire heads.

Sorters are one of the important part in logistics warehousing. They attach together after the Dimension Weigh Scan machine and receive orders from it to twist parcels left, right or front.

Sorter Advantages:

a'. Sort parcels to the designated exit port

Parcel sorting

Sort wheels twist three directions

The sort wheels are modular designed. Each twist plate is an independent part. Improved the working performance, singled maintenance on each twist plate and reduced maintenance cost.

The sorter wheels are cross installed in the hope of 100% sorting.

b'. The sorting line is modular design, flexible and easy to add more sorting destinations.

The DWS sorting line is upgraded to a modular design. It's flexible to customize as per customers' requirements, and easy installation:

2. Add more sorting destinations

Parameters

Parameters | Specifications |

Minimum size suggested | 150*150*20mm |

Maximum size suggested | 1200*1200*800mm |

Barcode reading direction | Top(three sides,five sides,six sides customizable) |

barcode reading rate | 99.99% (except for badly damaged barcodes) |

Working efficiency | 2600-3600pcs/h |

Power | different based on the quantity of sorters |

Belt width | 800mm/1000mm/1200mm |

Weighing accuracy | ±20g |

Dynamic weighing section | Single(Two dynamic weighing section customizable for large packages) |

Software | Camera system, DWS system, PLC control program |

Operation system | Windows 7/10 32/64bits |

Configurations | Smart cameras,3D cameras,Industrial computer, dynamic weighing components,PLC, servo motor, modular split belt conveyors |

Functions | parcel conveying, parcel singulating, barcode sccanning, weighing, (dimenssioning), parcel photoing, data uploading, sorting control |

Sorting destination quantity | Customization |

Package type: | Carton,soft package,woven bagged package |

Environment temperature | 0-50℃ |

Environment Humidity | 20-80%RH No condensation |

Successful Cases

Installation on-site

Recommend Products

About Us

Q&A

Q: Are you a manufacturer or trading company?

A: We are manufacturer specialized in truck loading & unloading, dimensioning.weighing scanning system and machines, parcel singulating, parcel sorting machines and overall solutions for logistics warehousing automation. With import and export license.

Q: Is the operation in English version?

A: We are manufacturer specialized in truck loading & unloading, dimensioning.weighing scanning system and machines, parcel singulating, parcel sorting machines and overall solutions for logistics warehousing automation. With import and export license.

Q: Is the operation in English version?

A: Yes

Q: How long does the production take?

A: Normally 35-45 days with commissioning.

Q: How can we assemble it on site ?

A: The machine is made in modular design, and simple structure. We will ship it in least further assembly and ship together with clear connection instruction. Only simple actions are needed to do.

Q: How do you assure the quality?

A: We only purchase parts and accessories from the leading manufacturers with qualified quality service.

All assembly is made within our factory. Quality can be well under monitor and control. Before shipment, all sections must be tested.

There's one year quality guarantee. During this period, all issues can be provided and served for free provided the reasons come from machine itself.

Q: I want to buy this equipment. How can I contact you?

A: You can directly place order in your browsing page and Alibaba will supervise the whole trade processes and assure the smoothness and safety.

You can also call or email or contact us with below direct contact.

Q: How long does the production take?

A: Normally 35-45 days with commissioning.

Q: How can we assemble it on site ?

A: The machine is made in modular design, and simple structure. We will ship it in least further assembly and ship together with clear connection instruction. Only simple actions are needed to do.

Q: How do you assure the quality?

A: We only purchase parts and accessories from the leading manufacturers with qualified quality service.

All assembly is made within our factory. Quality can be well under monitor and control. Before shipment, all sections must be tested.

There's one year quality guarantee. During this period, all issues can be provided and served for free provided the reasons come from machine itself.

Q: I want to buy this equipment. How can I contact you?

A: You can directly place order in your browsing page and Alibaba will supervise the whole trade processes and assure the smoothness and safety.

You can also call or email or contact us with below direct contact.

Why Choose Senad

◆ High-tech manufacturer with research and design capacity

◆ Concentrated on DWS equipments and sorting warehousing system overall solution

◆ Related software and system are with patents

◆ Stable and mature suppling system

◆ Young active sales and engineers for instant services(2-24hours online)

◆ Upgrading on mechanism according to ergonomics and easy maintenance

◆ Top quality sense, customers' requests come first

◆ Our structure design principle: easy maintenance & installation, low cost maintenance, maintenane not affect production

◆ Related software and system are with patents

◆ Stable and mature suppling system

◆ Young active sales and engineers for instant services(2-24hours online)

◆ Upgrading on mechanism according to ergonomics and easy maintenance

◆ Top quality sense, customers' requests come first

◆ Our structure design principle: easy maintenance & installation, low cost maintenance, maintenane not affect production

Contact Us

ATTN: May He

MP:+86-180 1627 5415 (wechat and whatsapp)

TEL:+86-21-5991 9555

FAX:+86-21-5992 0633

FAX:+86-21-5992 0633

EMAIL: may@senad.cn (Skype)

WEB: www.senadrobot.com

ADD.: No. 599,Huiwang East Road, Jiading, Shanghai China