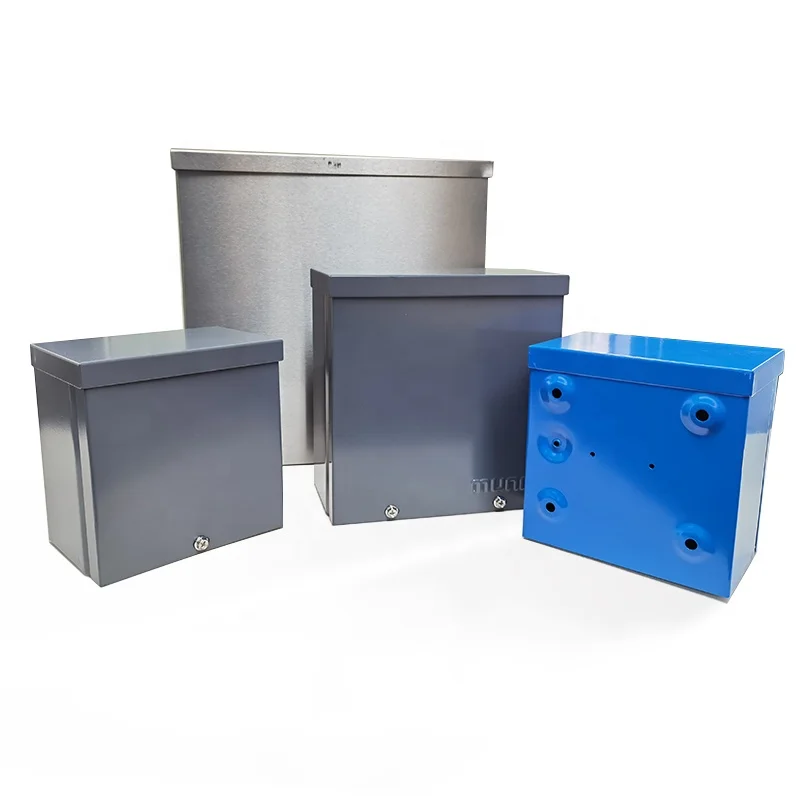

Наружный настенный Электрический корпус металлический панельный ящик алюминиевая электрическая распределительная

- Категория: Оборудование распределения электроэнергии >>>

- Поставщик: Sino,Industries,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.46 $* | 0.63 $* |

| Aug-18-2025 | 0.86 $* | 0.56 $* |

| Jul-18-2025 | 0.21 $* | 0.22 $* |

| Jun-18-2025 | 0.22 $* | 0.19 $* |

| May-18-2025 | 0.69 $* | 0.6 $* |

| Apr-18-2025 | 0.98 $* | 0.2 $* |

| Mar-18-2025 | 0.88 $* | 0.17 $* |

| Feb-18-2025 | 0.34 $* | 0.56 $* |

| Jan-18-2025 | 0.55 $* | 0.2 $* |

Характеристики

Company Profile

Sino Industries, we are OEM/ODM manufacturer of metal castings, forgings, precision CNC machining parts as well as assembly. We are able to provide one stop service from casting or forging to machining, surface treatment and heat treatment. As a privately owned company, we marked out our products throughout western Europe, like Germany, France, Denmark, Switzerland, Italy, Spain, etc, and North American of Canada and USA. Our commitment to quality has established us reliable long term suppliers for customers.

Sino Industries serves industries like automotive, construction machinery, off highway equipment, material handling equipment, agriculture machinery, etc.

Sino Industries serves industries like automotive, construction machinery, off highway equipment, material handling equipment, agriculture machinery, etc.

Our Production

Certifications

IATF 16949

ISO 9001

Product Description

Company | 16 years experience, ISO9001 and IATF16949 certified | |||

Main export market | Western Europe, North America | |||

Service | OEM Service | |||

Material | Carbon steel 1010 1020 1035 1045 Alloy Steel 4140 8620 | |||

Producing Process | Sheet Metal Fabrication | |||

Surface Treatment | Painting, zinc plating, etc as per customer requirement | |||

Inspection | CMM, spectrometer, microscope, tensile, hardness, etc. | |||

Packaging | VCI packing/Carton/Pallet/Crate | |||

Application | Automotive Agriculture, Forestry and Gardening Household appliances/facilities Machineries |

Sheet Metal Fabrication Process:

Sheet Metal Fabrication Process

1. Stamping: We have CNC punch presses and laser cutting machines to process the material for the first time.

2. Bending:The metal plate is processed by the folding bed and the bending mold to make it into a three-dimensional part.

3. Welding: Argon arc welding, spot welding, carbon dioxide shielded welding, manual arc welding, etc.

4. Surf Treament: Painting, zinc plating, e-coating or as per customer requirement

Why Choose Us

Quality is the priority | 1. ISO 9001 and IATF 16949 certified 2. 5S shop management 3. APQP, PPAP, SPC, FMEA, MSA | ||||||

Cost effectiveness | With profound knowledge in metal processing, we are able to choose the most optimized solution for each project. | ||||||

Delivery | Well planned production management/handling make sure on time delivery. | ||||||

Cross function team behind every sales coordinator | Behind the designaged sales coordinator, to support customer project, there is a cross function team consisting of process engineer, technic engineer, QA&QC, logistics, etc. | ||||||

Our Valued Customer

Trade Shows in Italy

Fluidtrans Compomac & Mechanical Power Transmission & Motion Control & BIAS

Packing & Delivery

VCI Packaging

Carton Packaging

Pallet Packaging

Crate Packaging

FAQ

Q1: How can I get cnc machining parts sample?

1. Sample fee will be free if we have in stock, you just need to pay the shipping cost is OK.

2. The sample of your own design needs to pay for the mold set upcharge. Samples production takes 5-7 working days after set up charge received & size drawing approval.

Q2: What is the shipping method?

Most of the goods were sent out by international airway express company like DHL, UPS, FedEx, TNT. Usually takes around 3-5 working days (door to door service). We also can arrange shipment via seaway.

Q3: How do you guarantee the quality of the products?

Strict product quality control, quality makes the future.This is the tenet of our factory. Each product from our factory has strict testing procedures, and must be 100% quality before delivery.