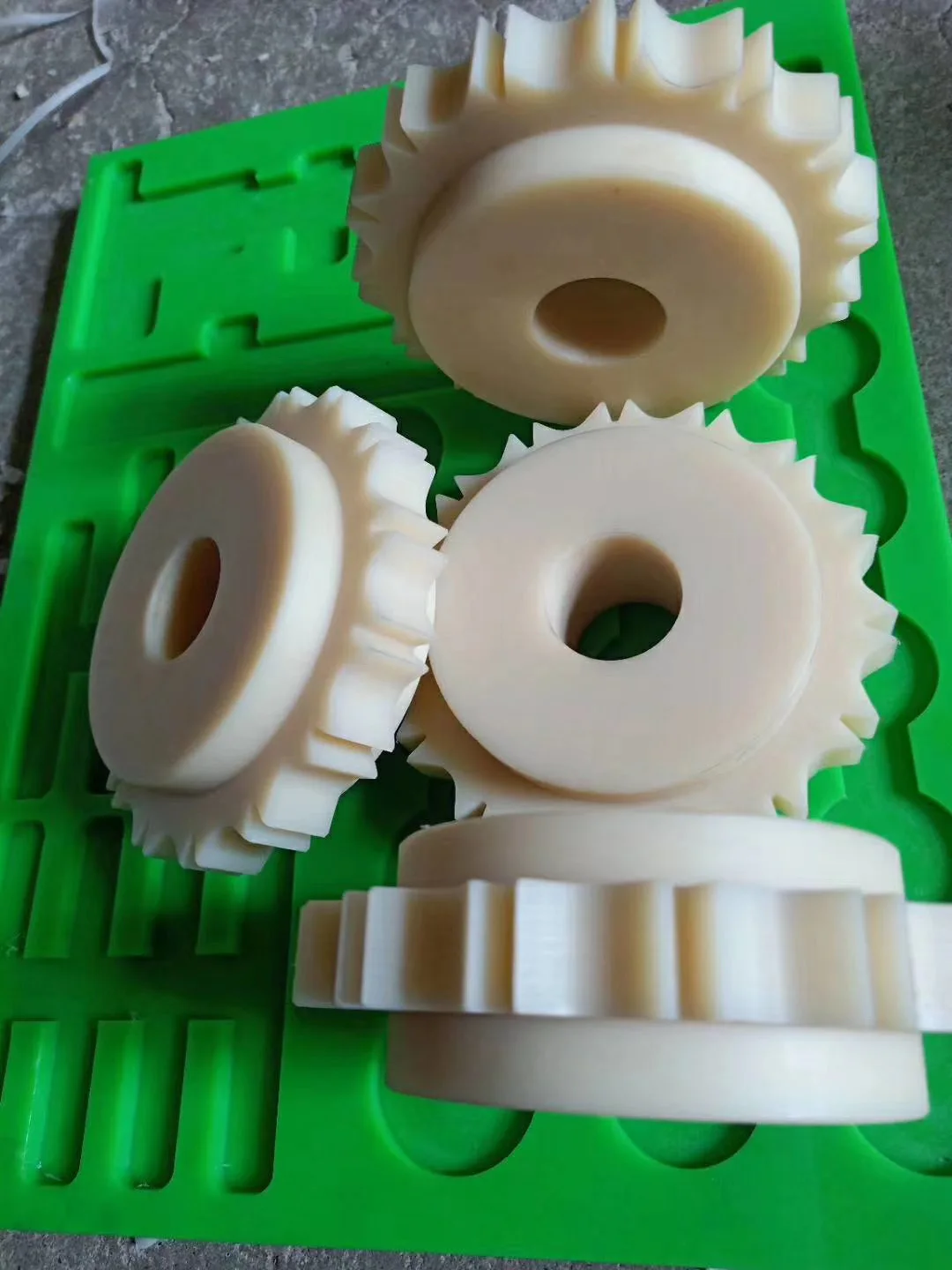

Машина с чпу изготовленная на заказ маленькая нейлоновая шестерня эпициклическая пластиковые детали для

- Категория: Spur Gears >>>

- Поставщик: Shandong,Jinmiao,Rubber,&,Plastic,Products,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.11 $* | 0.7 $* |

| Aug-19-2025 | 0.42 $* | 0.62 $* |

| Jul-19-2025 | 0.9 $* | 0.40 $* |

| Jun-19-2025 | 0.13 $* | 0.55 $* |

| May-19-2025 | 0.61 $* | 0.88 $* |

| Apr-19-2025 | 0.25 $* | 0.61 $* |

| Mar-19-2025 | 0.81 $* | 0.94 $* |

| Feb-19-2025 | 0.84 $* | 0.83 $* |

| Jan-19-2025 | 0.4 $* | 0.2 $* |

Характеристики

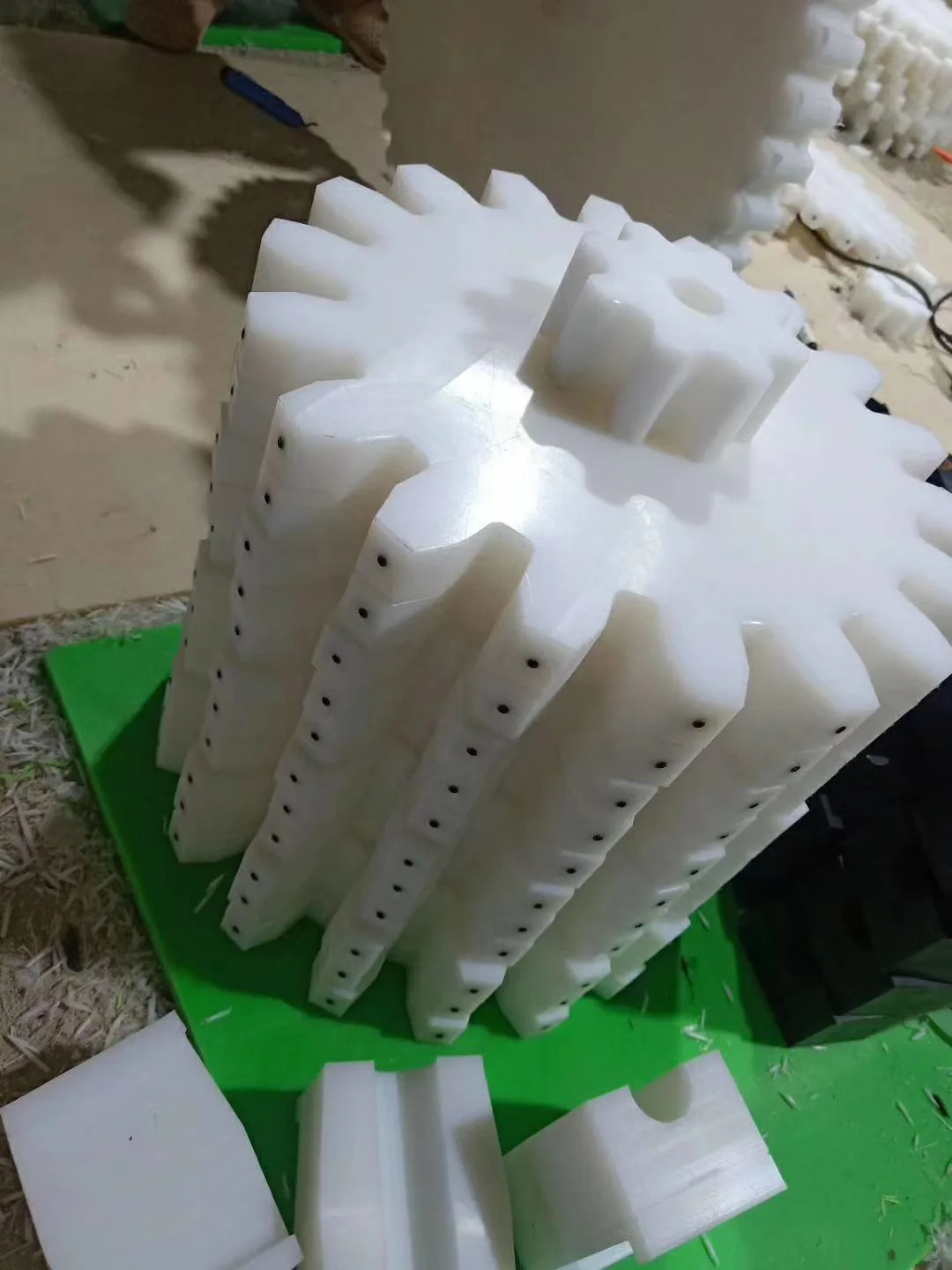

Detailed Images

* Lower cost:

Generally, plastic gears are less expensive to produce than metal gears. As there is usually no need for secondary finishing, plastic gears typically represent a 50% to 90% saving relative to stamped or machined metal gears, according to Plastics Technology.

* Design freedom:

Moulding plastic offers more efficient gear geometries than metal. Moulding is ideal for creating shapes, such

as internal gears, cluster gears, and worm gears, where the cost for forming them in metal can be prohibitive.

as internal gears, cluster gears, and worm gears, where the cost for forming them in metal can be prohibitive.

The superior noise-dampening properties of plastics result in a quiet running gear. This has made plastics essential for the high-precision tooth shapes and lubricious or flexible materials required in the ongoing quest for quieter drives.

* Lubrication:

The inherent lubricity of many plastics makes them ideal for computer printers, toys, and other low-load situations that require dry gears. Plastics can also be lubricated by grease or oil.

* Corrosion-resistant:

Unlike metal gears, plastic gears are immune to corrosion. Their relative inertness means they can be used

in water meters, chemical plant controls and other situations that would cause metal gears to corrode or degrade.

in water meters, chemical plant controls and other situations that would cause metal gears to corrode or degrade.

Plastic gears are more forgiving than metal because plastic can deflect to absorb impact loads. It also

does a better job of distributing localised loads caused by misalignment and tooth errors.

does a better job of distributing localised loads caused by misalignment and tooth errors.

Product Presentation

What is the Details of our products?

Name | Nylon Gear |

Material | Nylon,PEEK,PI,PEI,PU,PA,POM,PE,UPE,PTFE,etc. |

Color | White, black, green, nature, blue, yellow, etc. |

Condition | In stock/ Made to order |

Shape | As per your drawing |

Physical Properties | Physical Properties of Common Engineering Plastics |

Other Shape | Sheet, rod, tube, gear, rack, pulley, guide rail, plastics fittings, and so on |

Packing | Plastic bags, Cartons, Wooden case, Pallet, Container, etc. |

Other | Shipping status notification during delivery. Regular notification of new styles & hot selling styles. |

Feature: | Good abrasion resistance |

Application | Industry, medical and pharmaceutical, semiconductor, photovoltaic energy, chemical electronics, communications and other industries. |

Technological process:

1. Raw material preparation

2. Audit and design drawings

3. Processing products

4. Quality inspection

5. Repair product burr and inventory

6. Packing

2. Audit and design drawings

3. Processing products

4. Quality inspection

5. Repair product burr and inventory

6. Packing

Related Products

Certificate

Companies strictly enforce the ISO9001 (2008)

international quality certification system, the product quality conforms to the eu RoHS standard.

international quality certification system, the product quality conforms to the eu RoHS standard.

Company Introduction

Shandong Jinmiao Rubber & Plastic Products Co., Ltd. is located in the Economic Development Zone of Dezhou City, Shandong Province, It is one of the earliest companies engaged in composite materials, engineering plastics, rubber and plastic products.

Company's main products: all kinds of nylon bushings, wheels, slides, carrier rollers, gears, scale boards and other irregular parts; all kinds of ultra-high molecular weight PE(UHMW-PE) plate and other irregular parts; all kinds of injection molding parts with different material; all kinds of polyurethane plate and wheels ; all kinds of rubber products ; all kinds of oil nylon and large casting MC nylon irregular parts.

Main material: POM, MC Nylon, Oil Nylon, HDPE, ABS, PBT, PET, PVC, PC, PU, PP, PTFE, PVDF, PEI, PSU, PPS, PEEK, PAI, PI, PBI UHMW-PE.

Our company wide range of accessories processing conditions, such as mass customization production ability, exquisite

manufacturing technology and advanced production equipment, professional technical advice and after-sales service of products.

Companies strictly enforce the ISO9001 (2008) international quality certification system, the product quality conforms to the eu RoHS standard.

Company's main products: all kinds of nylon bushings, wheels, slides, carrier rollers, gears, scale boards and other irregular parts; all kinds of ultra-high molecular weight PE(UHMW-PE) plate and other irregular parts; all kinds of injection molding parts with different material; all kinds of polyurethane plate and wheels ; all kinds of rubber products ; all kinds of oil nylon and large casting MC nylon irregular parts.

Main material: POM, MC Nylon, Oil Nylon, HDPE, ABS, PBT, PET, PVC, PC, PU, PP, PTFE, PVDF, PEI, PSU, PPS, PEEK, PAI, PI, PBI UHMW-PE.

Our company wide range of accessories processing conditions, such as mass customization production ability, exquisite

manufacturing technology and advanced production equipment, professional technical advice and after-sales service of products.

Companies strictly enforce the ISO9001 (2008) international quality certification system, the product quality conforms to the eu RoHS standard.

Packing&Shipping

FAQ

1. Q: Are you trading company or manufacturer ?

A: We are manufacturer.

2. Q: How to get the quote ?

A: Please send your 3D drawings(PDF,STP, IGS, STEP...) to us, and tell us the material, surface treatment and quantities, then we will quote to you within 4 hours.

A: We are manufacturer.

2. Q: How to get the quote ?

A: Please send your 3D drawings(PDF,STP, IGS, STEP...) to us, and tell us the material, surface treatment and quantities, then we will quote to you within 4 hours.

3. Q: How long is your delivery time?

A: According to the difficulty and quantity of product processing,a reasonable arrival time will be given to you. Usually 2-5 days for CNC machine processing parts. It will take around 2-4 weeks for mold making.

A: According to the difficulty and quantity of product processing,a reasonable arrival time will be given to you. Usually 2-5 days for CNC machine processing parts. It will take around 2-4 weeks for mold making.

4. Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

5. Q: Can you do assembly and customized package for us?

A: We have an assembly factory and can assemble all kinds of plastic, metal and electronic parts for you. For the finished products,we can customized the retail package and you can sell it directly after receiving them.

A: We have an assembly factory and can assemble all kinds of plastic, metal and electronic parts for you. For the finished products,we can customized the retail package and you can sell it directly after receiving them.

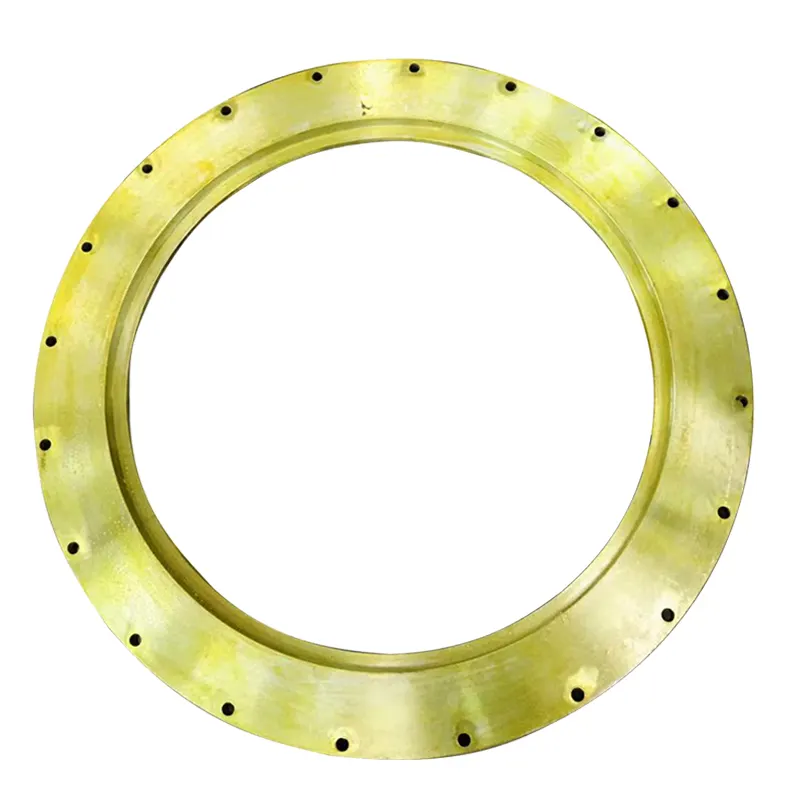

Похожие товары

Цементный смеситель Hino Crown Wheel и шестерни

US $5.79-$6.89

Спиральный угол 7, внутреннее спиральное кольцо

US $23.00-$87.00

OEM высококачественные медные шестерни из латуни

US $10.00-$99.00