Медные литейные трубки продолжают литье стержень из нержавеющей стали стальные R9m ccm 180x180

- Категория: Медь >>>

- Поставщик: ASTEC,Equipments,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 199206.12 $* | 209166.41 $* |

| Aug-16-2025 | 197532.32 $* | 207409.38 $* |

| Jul-16-2025 | 165726.40 $* | 174012.1 $* |

| Jun-16-2025 | 194184.51 $* | 203893.95 $* |

| May-16-2025 | 169074.44 $* | 177528.32 $* |

| Apr-16-2025 | 190836.92 $* | 200378.60 $* |

| Mar-16-2025 | 189162.0 $* | 198620.40 $* |

| Feb-16-2025 | 187488.18 $* | 196862.27 $* |

| Jan-16-2025 | 185814.78 $* | 195105.91 $* |

Характеристики

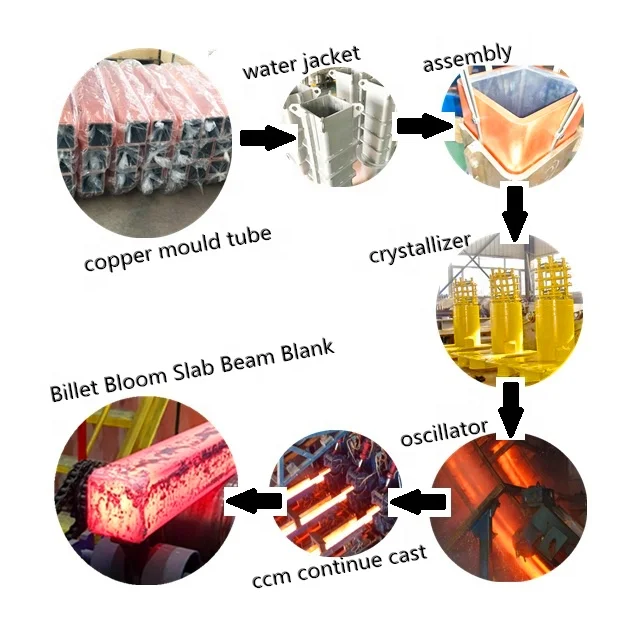

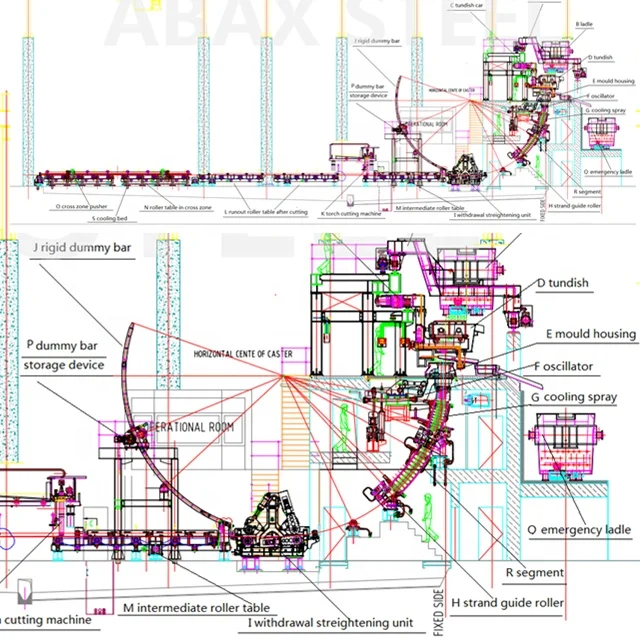

The continuous casting machine is mainly composed of tundish, crystallizer, oscillator mechanism, regid dummy bar, secondary cooling segment, withdrawal straightening unit, hydraulic sawing torch cutting machine, cross transfer zone, and walking beam cooling bed. Billet caster can also be desigend for quickly transfering hot billet to rolling mills.

In the process of producing various kinds of steel products in iron and steel plant, the ladle with refined molten steel is transported to the rotary turret. After the ladle turret is rotated to the pouring position, the molten steel is injected into the tundish, and then the molten steel is distributed to each crystallier Assembly copper mould tube by the tundish nozzle.

Copper mould tube is one of the core equipments of ccm continuous billet caster. It makes high temperature liquid steel solidify and crystallize rapidly to form steel castings. After electromagnetic induction stirring, the liquid steel in the copper mould is cooled and shaped, and then the casting is pulled out, and then the slab is divided into predetermined length by flame cutting machine ( Torch Cutting Machine).

The main components of the automatic control system for continuous casting include the speed control of casting roller, the control of mold vibration frequency, the control of fixed length cutting and other automatic control technologies.