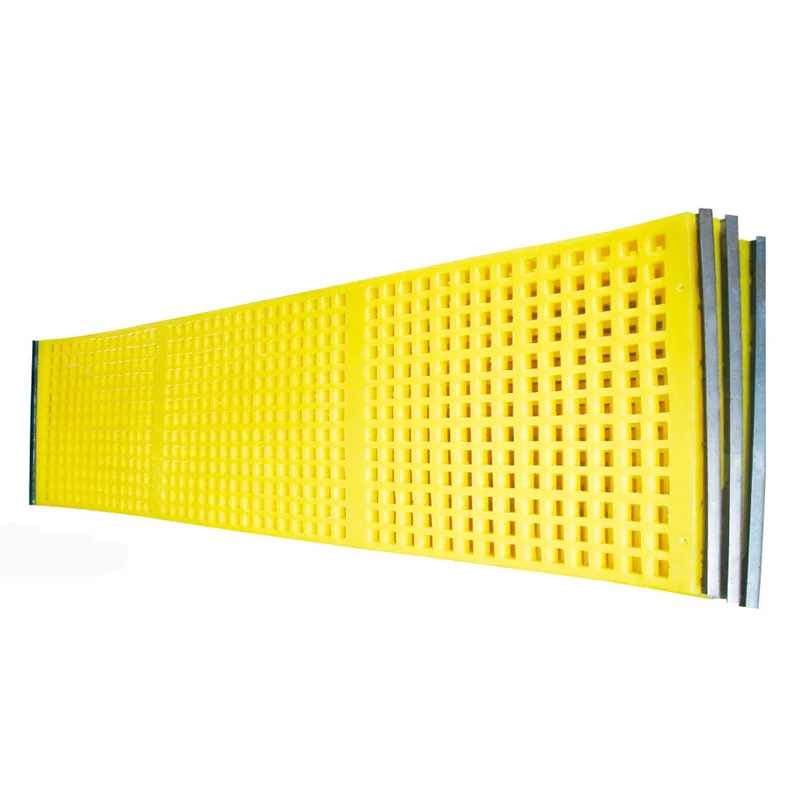

Высококачественные Полиуретановые горные экраны/вибрирующее сито/полиуретановая сетчатая панель сита используемая на

- Категория: Вибрационное сито >>>

- Поставщик: Hebei,Juming,Import,And,Export,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 1792.73 $* | 1882.87 $* |

| Aug-20-2025 | 1777.9 $* | 1866.90 $* |

| Jul-20-2025 | 1491.80 $* | 1566.57 $* |

| Jun-20-2025 | 1747.45 $* | 1834.25 $* |

| May-20-2025 | 1521.6 $* | 1597.46 $* |

| Apr-20-2025 | 1717.66 $* | 1803.76 $* |

| Mar-20-2025 | 1702.64 $* | 1787.46 $* |

| Feb-20-2025 | 1687.53 $* | 1771.28 $* |

| Jan-20-2025 | 1672.58 $* | 1756.95 $* |

Характеристики

polyurethane PU screen mesh is fabricated by advanced polyurethane materials with embedded metal framework structure, which combines all the characteristics of rubber sieve, but also have superior wear resistance, higher screening accuracy, better tear resistance.

The hole pattern, sheet size, raw material of perforated metal sheet can precisely made according to the customers' specifications, kindly let us know your request.

The polyurethane screen panels are a kind of screening media that made of polyurethane raw material. Which is also called polyurethane sieve plates.

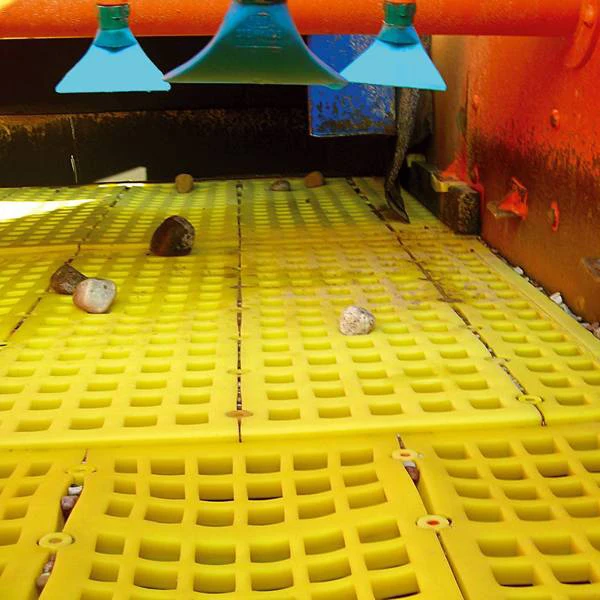

The latest production technology is adopted to made polyurethane screen panels have novel structure, convenient installation and disassembly. Polyurethane screen panels are widely used in metallurgy, mining, coal, building materials, water conservancy, road building and other industries on the screening machine. And PU screen panel is the replacement product of steel punching mesh, steel woven wire mesh, stainless steel sieve plates and rubber sieve plate.

2. Little work for maintenance, the polyurethane screen panel is heavy duty structured and hardly to be damaged under normal operation. Much time and efforts saved due to less maintenance and downtime.

Type:

2) tensioned polyurethane vibrating screen

3) modular polyurethane screen mesh

4) polyurethane dewatering screen

Application:

A:It is according to your quantity, normally 15 to 30 days;

Q: After sale service.

A: Every product will be inspected strictly before delivery. We'll in charge of all losses if there is any quality problem.

Q:What is the advantages com pared to other suppliers?

A:The unique full automatic roller production line, high machining accuracy, uniform and stable quality, which can realize continuous and efficient professional production, so we can provide good quality product and service to our customers.

Q:Can we visit your company?

A:No problem, we are a professional manufacturer, look forward to your arrival and we will lead you to visit our factory.

2. 20 years of production experience can ensure us to solve all the problems which our customers gave us.

3. Our products can be OEM and customized to reach customers' requirements.

4. We have strict product inspection and all the products we sell have to pass the inspection.

5. We have a professional 1 on 1 service team to ensure our customers can be replied on time and serve well.

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com