Автоматическая машина для ПЭТ-преформ пластиковых бутылок производственная линия YIZUMI высокоскоростная инжекционного метода литья

- Категория: Plastic Injection Machines >>>

- Поставщик: Guangdong,Yizumi,Precision,Injection,Molding,And,Die,Casting,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 222530.54 $* | 233657.55 $* |

| Aug-16-2025 | 220660.54 $* | 231693.3 $* |

| Jul-16-2025 | 185130.78 $* | 194387.74 $* |

| Jun-16-2025 | 216920.56 $* | 227766.51 $* |

| May-16-2025 | 188870.99 $* | 198314.29 $* |

| Apr-16-2025 | 213180.90 $* | 223839.12 $* |

| Mar-16-2025 | 211310.47 $* | 221876.63 $* |

| Feb-16-2025 | 209440.80 $* | 219912.6 $* |

| Jan-16-2025 | 207570.66 $* | 217949.18 $* |

Характеристики

Product Description

Yizumi provides tailor-made turnkey solutions for fast injection molding of PET packaging, including beverage bottles, oil bottles, food containers, daily necessities and medical products.

Injection unit

Single-station plasticizing ensures sufficient injection volume, maximum plasticizing volume up to 3,300 g.

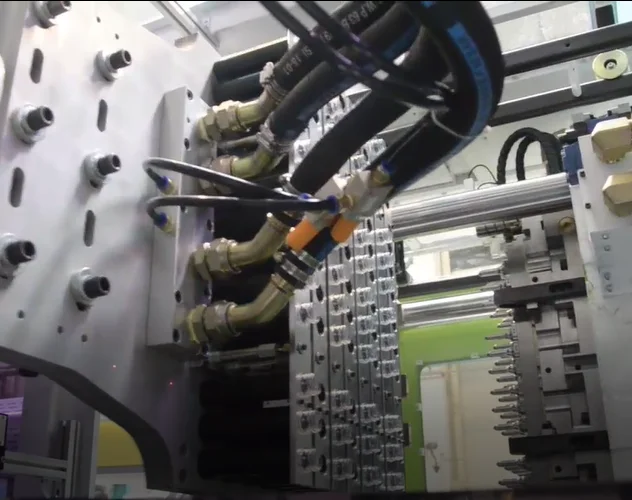

Clamping unit

Unique linear guide rails, non-contact tie bars, less resistance to movable platen and longer mold life

Electric dozing motor

Reduce production cycle time through parallel operation. Driven by servo motor, the dozing motor has higher energy conversation efficiency and saves more energy.

Cooling System

Unique automatic robot arm with cooling system inside. Reduce production cycle time by cooling and picking up products at the same time.

High response

High-end controller effectively improves and overlaps the response time of each movement. The program scan time is only 1ms.

Specification

item | unit | data | |

injection Unit | Shot volume | cm3 | 2098 |

Shot weight | g | 2370 | |

Screw diameter | mm | 90 | |

Injection pressure | Mpa | 1282 | |

Screw L:D ratio | 25:1 | ||

Screw stroke | mm | 330 | |

Screw speed(stepless) | r/min | 0-100 | |

Clamping Unit | Clamping force | kN | 2600 |

Opening stroke | mm | 700 | |

Space between bars | mmxmm | 755*755 | |

Max. Daylight | mm | 1240 | |

mold thickness(Min.Max) | mm | 220-700 | |

Hydraulic ejection storke | mm | 180 | |

Hydraulic ejection force | kN | 137 | |

Power Unit | Hydraulic system pressure | MPa | 17.5 |

Pump motor | kW | 63 | |

Heating capacity | kW | 46 | |

Number of temp control zones | 7 | ||

General Unit | Oil tank capacity | L | 700 |

Machine dimensions(LxWxH) | mxmxm | 8.5*2.1*2.2 | |

Machine weight | Ton | 18 |

NOTE: The listed machine price is for standard machine only, any extra requirement (e.g. CE/UL/KCS safety standard and so on) will be subject to extra charge.

Packaging & Delivering

Company Profile

Why Choose Us

Exhibition

Certifications

FAQ

Q1: Where is your factory located?

A1: Guangdong Yizumi Precision Injection Molding and Die Casting Technology Co., Ltd which is located at No.12, Shunchang Road, Daliang, Shunde, Foshan, Guangdong Province, China 528306

Q2: Are you an integrated supplier for injection molding machine, mold, robot and auxiliary?

A2: Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3: How about the quality control in your factory?

A3: Yizumi has the SOP (Standard Operation Procedure) and all the production step must follow up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully before shipment.

Q4: Will you offer the pre-sales service?

A4: Yes, we have an experienced pre-sales team to support customers not only including machine, mold and auxiliary selection but also water .electrical, machine layout in factory, etc.

Q5: What about the after-service? Will you send your engineer to my country to help commission and install the machine?

A5: Surely, we have many experience technical engineers for oversea service, they would help you install machine and support training to workers also. Currently we provide visit online by video call for the COVID-19.

Q6: What is the delivery time of the machine?

A6: Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery time of standard machine could be within 1-2 month

Q7 : What is the warranty of the machine ?

A7: The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Mold trial will be available in Yizumi factory ?

A8: Yes, Customer can send the mold to Yizumi factory and test.

Q9 . Do you provide any spare parts with machine?

A9: Yes, Yizumi will provide one set standard spare parts to customer including heater ,filter, screw head ,screw washer, checking ring ,sealings, etc.

A1: Guangdong Yizumi Precision Injection Molding and Die Casting Technology Co., Ltd which is located at No.12, Shunchang Road, Daliang, Shunde, Foshan, Guangdong Province, China 528306

Q2: Are you an integrated supplier for injection molding machine, mold, robot and auxiliary?

A2: Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3: How about the quality control in your factory?

A3: Yizumi has the SOP (Standard Operation Procedure) and all the production step must follow up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully before shipment.

Q4: Will you offer the pre-sales service?

A4: Yes, we have an experienced pre-sales team to support customers not only including machine, mold and auxiliary selection but also water .electrical, machine layout in factory, etc.

Q5: What about the after-service? Will you send your engineer to my country to help commission and install the machine?

A5: Surely, we have many experience technical engineers for oversea service, they would help you install machine and support training to workers also. Currently we provide visit online by video call for the COVID-19.

Q6: What is the delivery time of the machine?

A6: Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery time of standard machine could be within 1-2 month

Q7 : What is the warranty of the machine ?

A7: The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Mold trial will be available in Yizumi factory ?

A8: Yes, Customer can send the mold to Yizumi factory and test.

Q9 . Do you provide any spare parts with machine?

A9: Yes, Yizumi will provide one set standard spare parts to customer including heater ,filter, screw head ,screw washer, checking ring ,sealings, etc.