Пластиковая дробилка гранулятор аксессуары винт и баррель экструдер шнек

- Категория: Plastic & Rubber Machinery Parts >>>

- Поставщик: Zhejiang,Kehao,Plastic,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 8330.10 $* | 8747.58 $* |

| Aug-17-2025 | 8260.16 $* | 8673.17 $* |

| Jul-17-2025 | 6930.37 $* | 7277.22 $* |

| Jun-17-2025 | 8120.3 $* | 8526.31 $* |

| May-17-2025 | 7070.47 $* | 7424.5 $* |

| Apr-17-2025 | 7980.48 $* | 8379.2 $* |

| Mar-17-2025 | 7910.98 $* | 8306.83 $* |

| Feb-17-2025 | 7840.1 $* | 8232.23 $* |

| Jan-17-2025 | 7770.30 $* | 8159.43 $* |

Характеристики

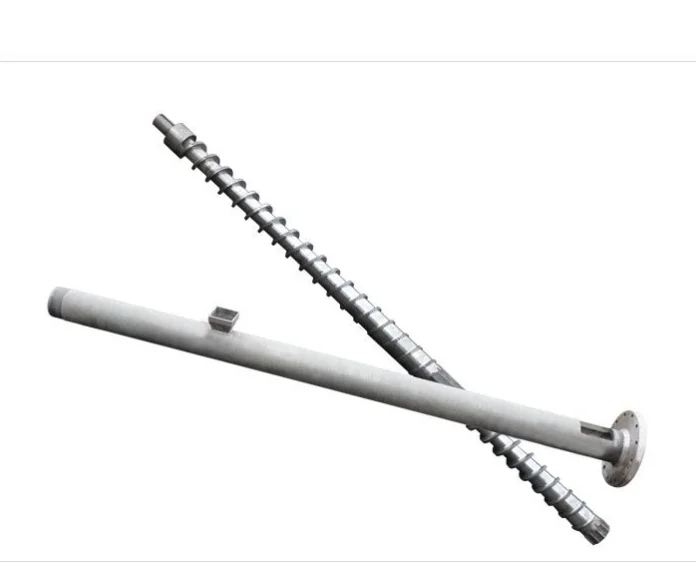

Plastic Granulator Pelletizer Accessories screw and barrel extruder injection screw barrel

1. Each screw is designed by the plastic character and output per hour.

2. Screw and barre are made of 38CrMoAl, after quenching, nitriding, and other treatment processes, different screw are designed according to the characteristics of different plastics. The screw inlet is sprayed ith special alloy material, which has strong wear resistance. Effectively improve the life of the screw.

3. Our engineer have been in this field for 15 years, effectively increased productivity and enhanced plastication and disperion. Increased the plasticizing effect of the material.

4. In general, the screw can be producted 3000-4000 tons granules.

The parameter of the scew

| Suitable for raw material | Length | Length:Diameter | Output(kg/h) |

| ABS PP PE LDPE HDPE PVC PPR | 100*2800 | 28:1 | 150-180 |

| 110*3200 | 180-230 | ||

| 120*3200 | 230-270 | ||

| 130*3600 | 250-320 | ||

| 140*3800 | 320-410 | ||

| 150*4200 | 410-500 | ||

| 160*4500 | 500-620 | ||

| Clean PP PE FILM | 130*4300 | 32:1 | 250-330 |

| 160*4500 | 500-570 | ||

| 180*5000 | 570-620 | ||

| CRUSHED FILM WOVEN BAG | 160*3200 | 20:1 | 220-260 |

| 180*3600 | 260-340 | ||

| 200*4000 | 340-420 | ||

| 230*4600 | 420-500 |

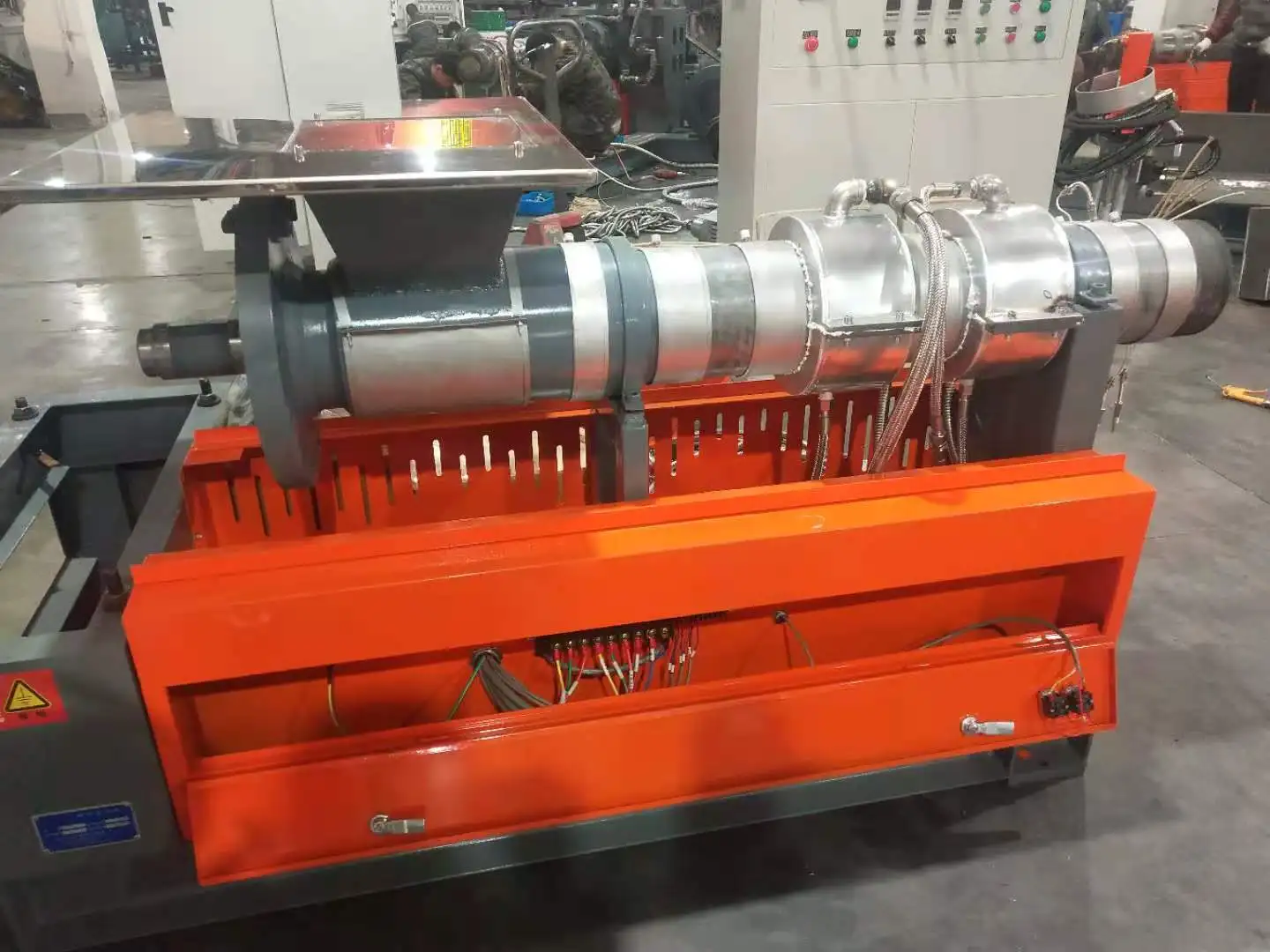

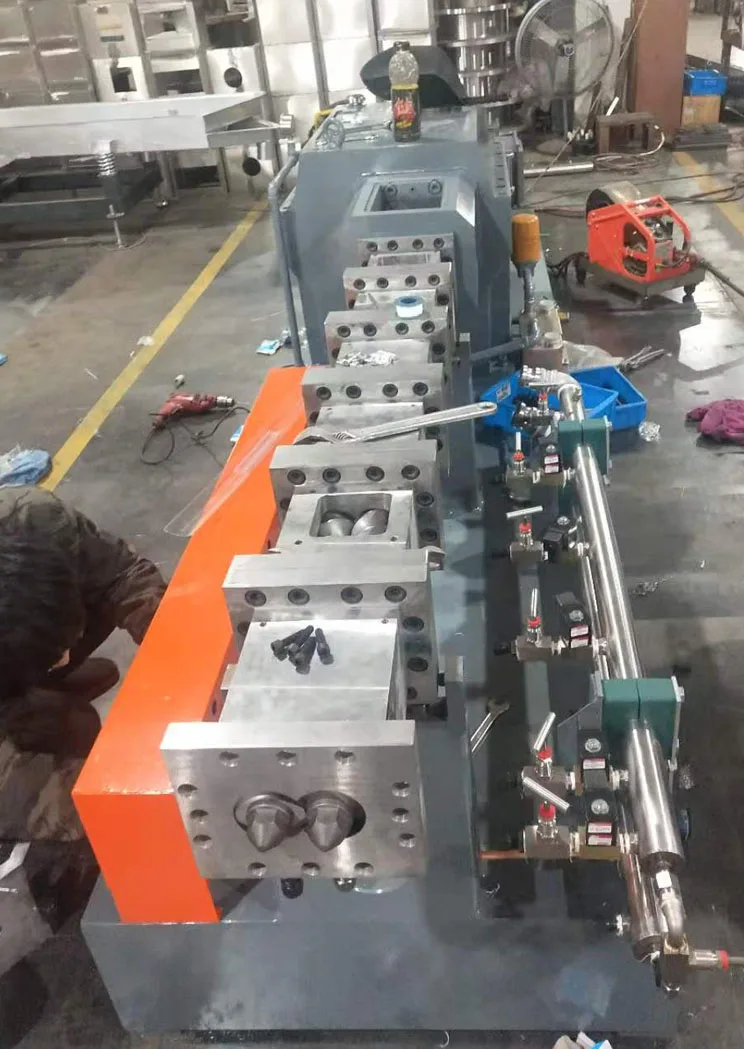

1.The blender is used to mix and heat wet plastics and additives.

2.The self-designed frequency feeder can separate magnetic impurities in the plastic.

3.Different feeders are designed for the characteristics of plastics, which can better protect the screw and feed evenly.

4.The raw material is 38CrMoAl, different plastic different screw.

5.Double station can change the net without stopping machine.

6.The second plasticization can better improve the quality and output of plastics.

7.The second filter to get better quality.

8.Use different length tanks for cooling plastic noodles.(Water can be recycled by water tower )

9.The pellets cutting machine with frequency(Siemens Motor,very low noise).

10.The high-power fan blows the particles to the storage bucket.

11.Store particles to reduce labor consumption.

Q1:Do you support overseas after-sales service?

A:Some countries support overseas after-sales service, the specific situation is negotiated.

Q2:how long is the warranty?

A:Within 1 year from date of the factory, if parts failure or damage

(because of the quality problem ,except wearing parts)

Q3:Do you provide technical support?

A:We provide lifelong technical support .Help each customer solve problems is our original intention.

Q4:The factors of plastic granulator line price?

1. Voltage and frequency in your country

2. The raw materials you are going to deal with, ABS PP PE PVC PET?

3. The output per day

4. The cleanliness of the raw materials, whether it needs to be cleaned (it is best to provide raw material pictures)

Q5:What is your payment term ?

A: 30% T/T in advance ,70% balance before shipment or Negotiable

If you have another question, please feel free to contact us as below