Высокая производительность угля гранулы брикета машина/уголь палки

- Категория: >>>

- Поставщик: Zhengzhou,Huayu,Briquette,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 2380.38 $* | 2499.14 $* |

| Aug-18-2025 | 2360.76 $* | 2478.26 $* |

| Jul-18-2025 | 1980.15 $* | 2079.39 $* |

| Jun-18-2025 | 2320.1 $* | 2436.63 $* |

| May-18-2025 | 2020.60 $* | 2121.0 $* |

| Apr-18-2025 | 2280.84 $* | 2394.35 $* |

| Mar-18-2025 | 2260.73 $* | 2373.46 $* |

| Feb-18-2025 | 2240.73 $* | 2352.85 $* |

| Jan-18-2025 | 2220.56 $* | 2331.35 $* |

Характеристики

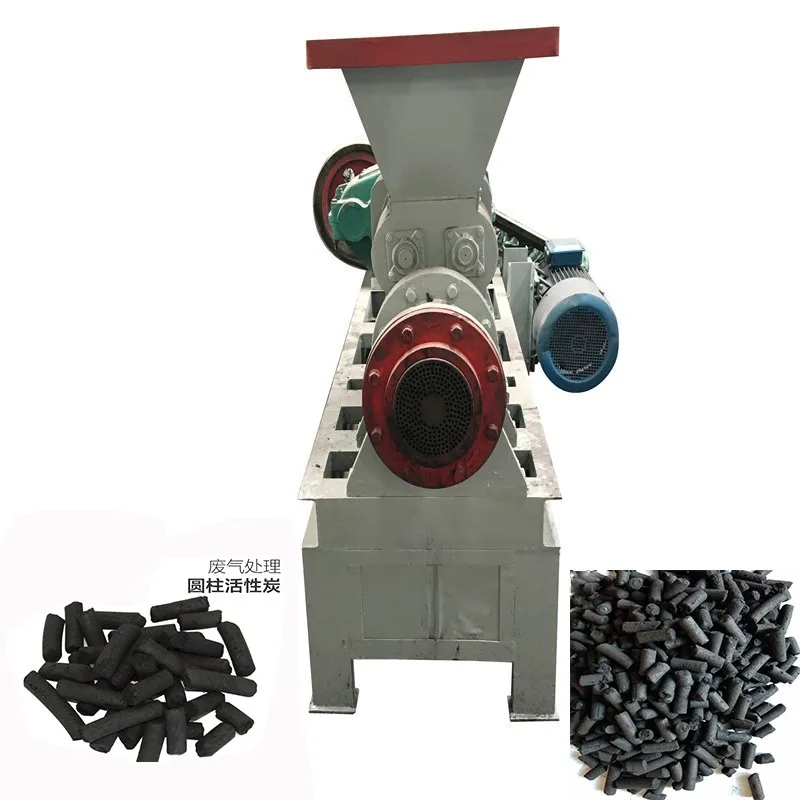

Coal/charcoal rod making machine

Coal rods machine (also called coal rod extrusion machine) is the use of the principle of screw extrusion, the modulation good pulverized coal compressed into a predetermined shape of a certain intensity of coal rods molding equipment. Charcoal is a kind of widely used fuel product both in our daily life and industrial use.For example, it is well accepted for BBQ because it is smokeless and odor free; it is a kind of ideal fuel source for the cold winter, so it becomes more and more popular. Besides, the charcoal can also be used in steel factories or many other industries. In a word, charcoal is in great demand recently. But the amount of natural charcoal is decreasing sharply. As a result, the machine-made charcoal becomes a good replacement.Usually the machine-made charcoal is made from sawdust or similar biomass powder (like straw, stalk, etc).

Features of the machine

a. Wide spread and common raw materials;

b. Wide application;

c. High density, small volume,good flammability;

d. Energy saving,no smoke,environment friendly.

1.\tThe overview picture of the machine

2.\tThe structure picture of the machine

asix cycloidal pin gear reducer, the number of rotation deceleration to the desired number of rotation, and obtain a larger torque

mechanism

service life.

3.\tThe working principle of the machine

After putting powdery materials into the machine inlet, the motor drives the screw to rotate to press them into different shapes of six arris or other forms.

A. Dry the material by drying machine or dried it in the sun, till the moisture is less than 12%.

B. Put the material into the feeding port of wood Briquette Machine.

C. Wood Briquette Machine can produce the briquette stick from biomass material without any additives.

Sleeves can be easily changed. Different shapes of sleeves make different shapes of products.

Model | MBJ-140 | MBJ-300 | MBJ-450 |

Yield(t/h) | 1-2 | 3-5 | 8-12 |

Power(KW) | 11 | 90 | 220 |

Helix diamter(mm) | 120 | 270 | 420 |

Spindle speed(r/min) | 60 | 132 | 132 |

In addition, there are other models which have different yield for you to choose from.

Many kinds of raw materials can be put into the machine, which include sawdust, iron, coal powder, etc.

A: Direct raw materials

The biomass rod making machine can output many shapes of finished products by different shapes of sleeves, and the size of finished products can also be customized as your requirements.

* Many kinds of materials can be put into the machine

* High yield, high efficiency and non-pollution

* More durable because of abrasion resistant paint

* Fully automatic control and electric heating device to ensure the stability of forming

Our company has more than 100 experienced workers and a complete set of production line which includes assembling, pressing, roller processing, case processing, and other workshops.

The follow pictures are our factory and workshops.

Please trust us. We have the best factory price and we have the enough ability and strength to manufacture high-quality machines in a timely and efficient manner.

Packing: We can install machines in the factory first or send the installation instructions to assist you.

Delivery: We usually deliver machines by One Touch of Alibaba Company in order to guarantee the delivery time and the quality of machines. We can also use other ways as your requirements.

Pre-Sales Service

* Inquiry and consulting support swiftly

* View our factory

* Using your mailed sample to test the machine

After-Sales Service

* Training how to install the machine and how to use the machine

* Engineers available to service machinery overseas

If you have any questions about the machine or our company, please contact us freely. We will response swiftly and do our best to meet your demand.