Лабораторный реактор высокого давления из нержавеющей стали с электрическим нагревом и функцией подъема 10 л 100

- Категория: >>>

- Поставщик: Weihai,Huixin,Chemical,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.18 $* | 0.4 $* |

| Aug-16-2025 | 0.59 $* | 0.60 $* |

| Jul-16-2025 | 0.51 $* | 0.78 $* |

| Jun-16-2025 | 0.94 $* | 0.79 $* |

| May-16-2025 | 0.76 $* | 0.49 $* |

| Apr-16-2025 | 0.93 $* | 0.47 $* |

| Mar-16-2025 | 0.56 $* | 0.0 $* |

| Feb-16-2025 | 0.14 $* | 0.39 $* |

| Jan-16-2025 | 0.99 $* | 0.65 $* |

Характеристики

Product Description

Electric heating high pressure stainless steel laboratory reactor

Electric heating high pressure stainless steel laboratory reactor

can also set the following options:

*Quick open design(split clamp with clamp bolts)

*Floor stand or moveable cart design

*Direct drive or belt drive optional

*Reactor lift / lowering / Tilting device.

*Magnetic and mechanical seal.

*Vacuum pump, Heating & cooling circulator, PLC control and others.

*Various impeller type available for mixing mission.

*Various Anti-corrosion alloy material available.

*Direct drive or belt drive optional

*Reactor lift / lowering / Tilting device.

*Magnetic and mechanical seal.

*Vacuum pump, Heating & cooling circulator, PLC control and others.

*Various impeller type available for mixing mission.

*Various Anti-corrosion alloy material available.

Application: Rearch/Lab, High pressure, high vacuum, high temperature condition. Chemical/Pharmaceutical, Syntheses, Reactor systems, Low temperature reactions.

Volume | 100ml-50 liters |

Pressure | Standard 100bar, Max.300bar |

Temperature | 350 ℃ |

Material | SS304 /SS316 |

Heating type | Electric Heating |

Cooling type | Internal spiral coils |

Impeller type | Propeller, Turbine, Anchor type |

Product Features

* Floor stands or moveable cart type.

* Laboratory autoclaves with 100 ml to 50 liters volume.

* Max pressure: 300 bar; Max temperature up to 500 ℃

* Low to high torque magnetic couplings: static seal with no leakage.

* Laboratory autoclaves with 100 ml to 50 liters volume.

* Max pressure: 300 bar; Max temperature up to 500 ℃

* Low to high torque magnetic couplings: static seal with no leakage.

* Continuous feeding system.

* Reflux model:Equipped with external condenser, reflux tube line.

* Receiving model:Equipped with external condenser, receiving tank.

* Available material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel

* Smooth run, low noise and easy operation.

* Monitor and control: Temperature, pressure, motor speed, working time, etc

* Safety Device (Blasting Disc) on Security Blasting Port.

* Customized according to customers requirement.

* Reflux model:Equipped with external condenser, reflux tube line.

* Receiving model:Equipped with external condenser, receiving tank.

* Available material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel

* Smooth run, low noise and easy operation.

* Monitor and control: Temperature, pressure, motor speed, working time, etc

* Safety Device (Blasting Disc) on Security Blasting Port.

* Customized according to customers requirement.

Special alloy available

Titanium, Nickel, Hastelloy, Zirconium

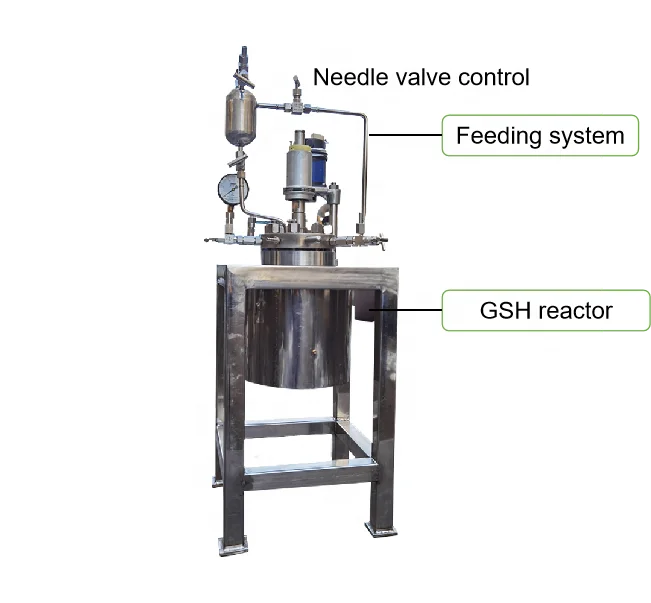

Feeding system

Continuous and stable feeding under high pressure

Magnetic couplings

Static seal with no leakage.

Internal Drawings

* Internal spiral coils

Quick coolings for material

* Dip tupe device

Used for up discharging

* Various impeller available

Propeller, turbine, anchor, others

Used for up discharging

* Various impeller available

Propeller, turbine, anchor, others

Magnetic Stirrer

* 100% Sealing. Zero leakage.

* Zero emission of hazardous fluids.

* Suitable for pressure fluctuations.

* Various capacities available.

* Compact Design.

* Suitable for pressure fluctuations.

* Various capacities available.

* Compact Design.

Control system

Intelligent digital temperature control

with the temperature, stirring speed display & control and working time display

Size Information

Quick selection

Type | GSH-0.1~1 | GSH-1~10 | GSH-10~25 | GSH-25~50 | GSH-5 | |||

Volume(L) | 0.1~1 | 1~10 | 10~25 | 25~50 | 5 | |||

Working pressure(MPa) | -0.1~30 | -0.1~30 | -0.1~30 | -0.1~30 | 10 | |||

Motor power(W) | 40~80 | 80~200 | 300~750 | 1100 | 350 | |||

Heating power(KW) | 0.1~1 | 1~3 | 3~6 | 4~9 | 0-1500 | |||

Working temperature(°C) | -196~500 | 0.6 | ||||||

Stirring speed(r/min) | 0~1500 | 4 | ||||||

Heating type | Electric heating, thermal oil heating available | |||||||

Cooling Method | Spiral coils(Single coils, serpentine coils available) | |||||||

Charging type | Charging from above, discharging from bottom. | |||||||

Stirring type | Customized anchor-type, frame-type, propeller type, turbine-type, scraper-type or paddle-type...etc | |||||||

Seal type | Magnetic seal, mechanical seal, | |||||||

Motor | General DC motor, DC servomotor or explosion-proof motor according to customers’ requirements. | |||||||

Controller Device | Temperature, time and heating voltage display Temperature adjustment control, accuracy±1 ℃ Stirring speed display and control,Others | |||||||

Standard fittings | Pressure Gage; Thermocouple; Internal Stirring System Liquid inlet and gas inlet with needle valve;Gas Release Valve Dip Tube; Safety Rupture Disc; Cooling Coil | |||||||

Product Details

Reasonable and compact structure.

Customized according to customer process requirements to ensure high efficiency, beauty and high service life.

Magnetic stirrer.

100% Sealing. Zero leakage.

Zero emission of hazardous fluids.

Agitator optional.

Various impeller type available for mixing mission

Head lifting.

The head of reactor can be lifting.

Easy use and less labor cost.

Feeding system.

Continuous and stable feeding under high pressure.

Safe and reliable.

Pressure gauge, safety device with bursting disc, safety valve and complete test report.

Related Products

Company Profile

Weihai HuiXin Chemical Machinery Co ,. Ltd

Weihai HuiXin Chemical Machinery Co ,. LTD was established in 2005. In the past 15 years, When our enterprise was first set up, its scale was smaller and its business was relatively simple. With our joint efforts, HUIXIN has a number of patent core technology, as well as dozens of excellent technical engineers. We have the most advanced production equipment and strict quality control system,A1,A2 design and manufacture of pressure vessels, ISO、CE certification, which ensure product quality absolutely perfect and the goods on time period.

Our manufactory locate at WEIHAI, SHANDONG Province, and occupies over 40 thousand square meters. There are 5 workshop, the usable area bonus is 20,000 square meters .The convenient transportation and ocean developed is a advantage to the other manufactures . We have the ability to manufacture and ship super heavy containers for overall delivery.