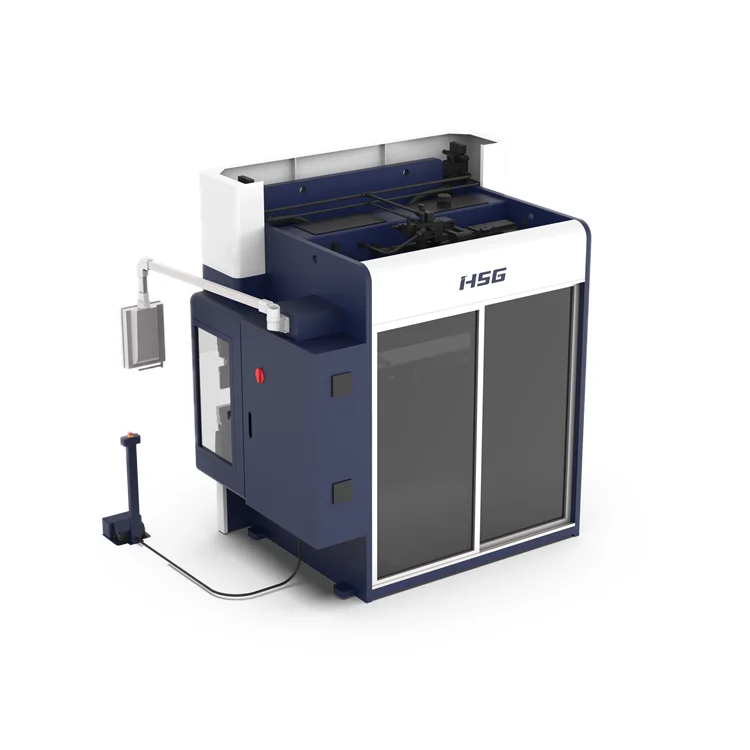

Завод высокое качество cnc трубы серии HB Масло Электрический Гибридный Металл Гибочный

- Категория: Кромкогибочный пресс >>>

- Поставщик: HSG,Laser,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 35700.23 $* | 37485.1 $* |

| Aug-18-2025 | 35400.45 $* | 37170.93 $* |

| Jul-18-2025 | 29700.58 $* | 31185.70 $* |

| Jun-18-2025 | 34800.0 $* | 36540.85 $* |

| May-18-2025 | 30300.33 $* | 31815.39 $* |

| Apr-18-2025 | 34200.26 $* | 35910.63 $* |

| Mar-18-2025 | 33900.70 $* | 35595.53 $* |

| Feb-18-2025 | 33600.64 $* | 35280.31 $* |

| Jan-18-2025 | 33300.7 $* | 34965.58 $* |

Характеристики

Product Description

The basic unit of the machine

Machine bed

Cylinder and slider

Hydraulic system

Electrical control system

Backgauge system

Control System

Mould

Front pallet

Cylinder and slider

Hydraulic system

Electrical control system

Backgauge system

Control System

Mould

Front pallet

1. Machine bed

This component is composed of left and right column, oil tank, workbench, deflection automatic compensation system, etc.In the process of bending plate, the slider and the workbench would inevitably produce flexural deformation, thus make the workpiece bending Angle is small at both ends, the middle state, degree of compensation system of official work in order to compensate the deflection, make the workbench produces prestressing to track slider flexural deformation, change the Angle of the workpiece on the bending length - control in the tolerance range.

Electrical control system

Electrical components are imported brand, in line with international standards, safe and reliable, electric control cabinet cooling function with movable foot switch control station, with startup, shutdown and emergency stop functions;The wiring of the

electric cabinet is reasonable and clear, which is convenient for maintenance or troubleshooting.

electric cabinet is reasonable and clear, which is convenient for maintenance or troubleshooting.

Rear stopper system

· It is compact, firm, with small inertia, fast speed and high precision

· The forward and backward movement (X-axis) and up-down movement (R-axis) are driven by the servo motor.

· Equipped with 4 positioning finger

· The forward and backward movement (X-axis) and up-down movement (R-axis) are driven by the servo motor.

· Equipped with 4 positioning finger

The mold

This part is composed of upper die component and lower die component.The upper die is mounted on the fast die clip and fixed by

the pressing plate to the upper die with different length segments. The required length can be assembled according to the requirements of the workpiece.

the pressing plate to the upper die with different length segments. The required length can be assembled according to the requirements of the workpiece.

Specification

Bending force | 500KN |

Working table length | 2050mm |

Height of worktable | 920mm |

Column spacing | 1600mm |

Throat depth | 320mm |

Slider stroke | 160mm |

Maximum opening height | 420mm |

Rapid descent | 180mm/s |

Return speed | 140mm/s |

Speed of work | 10mm/s |

Backgauge (x axis) stroke | 0-500mm |

X axis positioning accuracy | ±0.1mm |

X axis repeat positioning accuracy | ±0.02mm |

y-axis positioning accuracy | ±002mm |

Y-axis repeat positioning precision | ±0.02mm |

Degree R axis stroke | 150mm |

Working accuracy | Straight line: 10.2mm/m, angle: ±0.5mm/m |

Number of CNC axes | 4-axis |

main motor power | About 5KW |

Fuel tank capacity | 160L |

Dimensions | About 2400x1500x2480mm |

Whole equipment weight | About 4000KG |

Company Profile

HSG Laser Co., Ltd.

HSG Laser, founded in 2006, as a national hi-tech enterprise with an eye to R&D, production and sales of laser equipment, is now mainly dedicated to serve global customers with intelligent metal forming solutions. Starting from China, HSG Laser has expanded its service network to 100+ countries and regions after 14 years of high-quality development. It has two wholly-owned subsidiaries in global industrial powers, Germany and Japan, and creates its own high-end brand Xlase. In China, four standardized intelligent equipment manufacturing bases have been completely built in its headquarters (Foshan City), Puhang, Suzhou and Jinan. HSG frame also includes 2 domestic subsidiaries, 3 branches and 20 operation service centers.

HSG Laser, founded in 2006, as a national hi-tech enterprise with an eye to R&D, production and sales of laser equipment, is now mainly dedicated to serve global customers with intelligent metal forming solutions. Starting from China, HSG Laser has expanded its service network to 100+ countries and regions after 14 years of high-quality development. It has two wholly-owned subsidiaries in global industrial powers, Germany and Japan, and creates its own high-end brand Xlase. In China, four standardized intelligent equipment manufacturing bases have been completely built in its headquarters (Foshan City), Puhang, Suzhou and Jinan. HSG frame also includes 2 domestic subsidiaries, 3 branches and 20 operation service centers.

Certifications

After-Sales Service

Pre-sales Service

Pre-sales Technical Consultation

According to customer requirements, providing customers with product information, technical consultation, technical guidance,

assisting customers or customizing professional laser processing solutions for customers through a variety of channels such asnetwork, telephone, letter, and door-to-door service.

assisting customers or customizing professional laser processing solutions for customers through a variety of channels such asnetwork, telephone, letter, and door-to-door service.

After-Sales Service

24/7 Service

24/7 Service

Packing & Delivery

FAQ

1. I knew nothing about this machine, what kind of machine i should choose?

4. Where is your headquarters?

-So easy . Just tell us what you want to do by using laser machine, then let us give you perfect solutions and suggestions.

2. What can it welding?

-Laser machine for metal usually deal with carbon steel, stainless steel, aluminum, brass and alloy.

3. How long is the warranty?

-We offer 1-year warranty.

4. Where is your headquarters?

-Our headquarters is in foshan, Guangdong Province, China.

5. Can I visit your factory?

-Of course.Please contact us any time . We will arrange in advance.

6. Do you have engineer to teach me/my workers?

-Yes, we offer free training for each customer. We promise to help until everything gets right.

Похожие товары

Wc67y гидравлический гибочный станок из нержавеющей стали 125 тонн

US $13900-$14080

Гидравлический листогибочный пресс

US $30000