60 Nm3/hr chimenea vapor ambiente и высококачественный алюминиевый испаритель СПГ окружающего

- Категория: Теплообменник >>>

- Поставщик: Suzhou,Wintek,Machinery,Engineering,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-17-2025 | 1.74 $* | 1.31 $* |

| Jul-17-2025 | 1.36 $* | 1.16 $* |

| Jun-17-2025 | 1.10 $* | 1.0 $* |

| May-17-2025 | 1.62 $* | 1.39 $* |

| Apr-17-2025 | 1.39 $* | 1.57 $* |

| Mar-17-2025 | 1.95 $* | 1.37 $* |

| Feb-17-2025 | 1.40 $* | 1.99 $* |

| Jan-17-2025 | 1.78 $* | 1.52 $* |

Характеристики

Our Services

Model | Flow | Inlet Pressure | Discharge Pressure | Inlet Temperature | Outlet Temperature | Medium |

Nm3/h | MPa,G | MPa,G | deg C | deg C | ||

QQ-60/16 | 60 | <1.6 | <1.6 | -196~-50 | Ambient tempearture- 10 deg C | Liquid oxygen, nitrogen,argon, CO2, LNG,etc. |

Ambient Cryogenic Liquid Vaporizer

Instruction Manual

Safety instruction

Any operation of the cryogenic liquids or gases under various working pressures must comply with the related safety regulations strictly. Otherwise, there will be a likelihood of causing deadliness or serious injury.

When used for liquid oxygen medium, all the pipelines, units, and components that may be exposed to liquid oxygen or oxygen must not be contaminated with oils. Otherwise, it is possible to cause fires, explosion, or fatal injury.

Electrical wiring shall be properly performed by the persons with relevant qualifications in accordance with technical standard or regulations on electrical equipments. Wiring error may lead to electric shock, damage to unit, and fires.

Hoisting of Large units must adopt appropriate and safe lifting facility, and perform in strict compliance with lifting strategy. When hoisting, should load up gently and load down lightly. Dont permit personnel to approach during hoisting process, to prevent dangers from colliding with the unit or from dropping down of unit.

Product overview

This series of cryogenic liquid vaporizer is a kind of energy-efficient heat exchange unit, which utilizes its ambient air as a heating source, and heats cryogenic liquid (LIN,LO2,LAR,LCO2,LNG,etc.) in the heat exchange pipe through natural convection of its ambient air, making it totally evaporate into the gas.

,

The product is featured with both structure and heat exchange process in modern design, and large heat exchange margin. Generally, it would be best to be installed in the open air in order to better heat exchange with ambient air. The unit adopts better heat exchange efficiency, and antirust aluminum alloy materials with property of oxygen corrosion resistant. Thus, it has long service life, as well as less light weight. It also has advantages such as no other energy consumption, no any pollutions, no need to maintain, elegant appearance, extremely easy operation, and so on. Therefore, it can save large amount of unit operating cost, which has been recognized by a very wide range of users.

Technical parameters

Model QQN-1000/1.7

Applicable media LO2/LN2/LAr

Operating pressure 1.7Mpa

Gasifying capacity 1000NM3/h

Ambient temperature -15+65

Outlet temperature approach to ambient temperature

Overall dimension 5.4X2.04X2.04m

Equipment weight 1000kg

Construction description

,

The serial vaporizer is vertical ambient air unit with big star-shaped fins, nozzle connections at both liquid inlet and gas outlet adopt stainless steel flanges specialized for low temperature, sealing with metal gaskets specially designed for low temperature, diamond-shaped compensation joints between finned tubes , bridge type connections all around the unit edges, its periphery uses high intensity and antirust aluminum alloy aluminum trough as transport protection frame, providing a simple and aesthetic entire construction, not easy to frost, eliminating the stress caused by expanding with heat and contracting with cold in normal use.

Installation instruction

5.1

Firstly vaporizer shall be located on the smooth concrete foundation outdoors, calibrate its levelness and verticality carefully, to avoid the bias current, and other operating failures.

5.2

When installing, should pay attention to its inlet and outlet directions. Otherwise, it will affect its gasification capacity or operation danger caused by it.

5.32

Keeping a distance of more than 2 meters above with its surrounding other vaporizers or barrier is recommended, base plates of the unit shall be fixed reliably and effectively by the use of foundation bolts or anchors.

5.4

When unit is connected to pipelines, nozzle connections for liquid inlet and gas outlet must follow process piping requirements supplied by professional design department. Considerations must be given to installing stainless steel cryogenic hose with equal caliber or to designing effective pipeline compensation measure at the liquid inlet of ambient vaporizer in process pipeline, so as to protect welds of inlet aluminum pipe from tension fracture due to external cryogenic pipeline cold contraction, resulting in damage to unit and accidents.

5.5

Installing low temperature alarm or interlocking device at Outlet header pipe of ambient vaporizer shall be taken account of, to prevent carbon steel pipelines from explosion due to cold brittleness, or to avoid damage to facility of downstream unit, caused by excessively low outlet medium temperature after long time continuous use of the unit.

5.6

After completing all the site pipeline installation, shall inspect according to related nation requirements. As soon as result is qualified, it is recommended to take professional and effective thermal insulation treatment in liquid inlet section pipeline.

5.7-196

In view of lower operating temperature at heat exchange pipe surface, at about -196 or so, during the periods of ambient vaporizer working. In order not to allow external personnel to approach easily, recommend relative partition wall measure at the whole station area or around the unit should be considered, to avoid deep frostbite of personnel, or causing danger.

Operation and maintenance instruction

6.1Pre-use Check

1.530

Check the unit tightness prior to use, and tightness test check is conducted with clean, dry nitrogen. Employ pressure gauge accuracy of 1.5 grade or more to test, test pressure is maximum working pressure, dwell time is 30 minutes, without any leakages in compliance. If leakage found, should seek for leak point in time, it is obliged to contact the manufacturer immediately to eliminate hidden dangers before use.

6.2Operating procedure

6.2.1

Primarily close all the feed liquid valve and vent valve in the system, and then open feed liquid valve slowly, while frost mist occurring on outer pipe, start up vent valve slowly, continue to turn up gradually, dont attempt to stabilize valve opening until the unit reach to the rated gasification capacity (specific to middle low pressure series).

6.2.2()3-5

Particular care should be taken to the operation of larger vaporizer(each unit 2000NM3/h above), each time should open(or switch) feed liquid valve very slowly, normally timing control for opening valve should be within 20 to 30 minutes or so, dont open the valve in full open position until the unit being cooled thoroughly. The whole unit without any contraction sounds shows pre-cooling is completed. Avoid unit heat exchange pipe to exert strong stress on weld generated by abruptly cold contraction, causing leakage.

6.2.3

If outlet temperature of the unit is too low, causing outlet pipe frosting. This indicates that feed liquid volume is excessive, or continuous service time too long . In this case, feed liquid valve must be turned down immediately so as to prevent fluid from passing , and it is timely to remove frosting from outside pipe, and increase ventilating device or take other relevant measures, to protect outlet pipe of the unit from being brittle caused by low temperature gas, resulting in explosion. As a rule, frosting for normal gasification is one third or so, no more than a half, it is necessary to switch or take measures promptly in excess of frosting range.

6.3Degreasing treatment

Liquid oxygen vaporizer is absolutely free of oil. While operating, workers should wear oilfree heat insulating gloves, and safety goggles in order to protect unit from being contaminated, and operators from injury. When identifying that vaporizer is contaminated with oil, heat exchange pipe or contaminated parts should be degreased and cleaned, including the following several steps:

6.3.16080

Clean repeatedly with hot water of 6080.

6.3.280100

Purge with nitrogen heated to 80100 until confirming dried and oil-free.

6.3.3

8010020M/S

When oil contamination is serious, should be cleaned using acetone, and finally purge with nitrogen heated to 80100 at a speed of 20M/S until making sure of dried up.

6.3.4

Cleaning process for contamination under special situation should be completed at the factory after manufacturer provide cleaning strategy.

6.3.4

Cleaning and purging should strengthen awareness. When cleaning, should wear labor protection appliances such as gas mask, safety goggles, etc

Other instructions

7.1682

Gasification capacity for this serial vaporizer is not fixed absolutely. Rated flow generally refers to gasifying flow of unit continuous service for 6 to 8 hours, overtime operation may lead to decreasing gasification capacity and outlet temperature. For working condition of continuous service, it is recommended to adopt two sets of same size vaporizers to switch to use.

7.212

The product must be checked for leaks at regular intervals of 12 months.

7.3

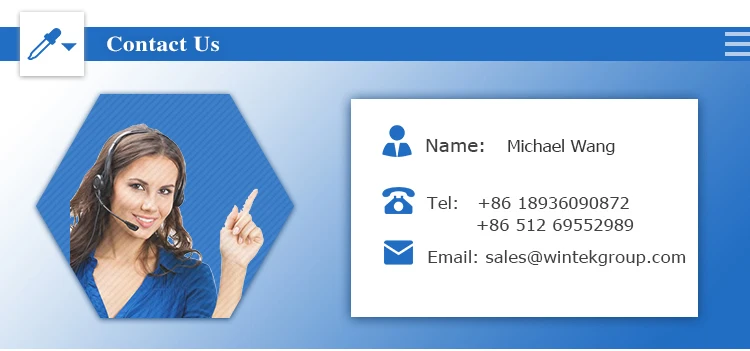

For any other questions, please contact the dealers or our company quickly, Our company can provide users with timely and thoughtful service.

Service phone(86-512)-66512050

Operating characteristics curve for ambient vaporizer

Remarks

8.14050%1.5t=10

Best atmospheric conditions: atmospheric temperature at around 40, 50% relative humidity, used in breeze state, 1.5 times of rated gas output, tout =10.

8.22070%1.25t=10

Better atmospheric conditions: atmospheric temperature at around 20, 70% relative humidity, used in breeze state, 1.25 times of rated gas output, tout =10

8.3090%1.0t=10

Worst atmospheric conditions: atmospheric temperature at 0 or below, 90% relative humidity, used in breezeless state, 1.0 times of rated gas output, tout =10

8.46868246

8

Continuous service time designed for this vaporizer is for 6 to 8 hours, its flow can reach rated gasification value. Beyond the service time range, its gasification effects will be diminished due to frosting and freezing on the finned tubes, and other causes. Therefore, it is recommended that users switch to employ two sets of standard vaporizers in case of continuous operation for over 6 8 hours. Switching time may be 4 hours, 6 hours, or 8 hours , and master flexibly depending on local climatic conditions so that the shut down vaporizer have time enough to automotive defrosting.

Q1: How about the quality of your products?

A: Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery. You can also use Trade Assurance by Alibaba for product quality protection, on-time shipment protection and payment protection.

Q2: How about the price?

A: We are manufactory, and we can give you lower price than those trade companies. Besides, customers from Alibaba can geta discount.

Q3: Do you provide after-sale service?A: Yes. The warranty peniod of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.