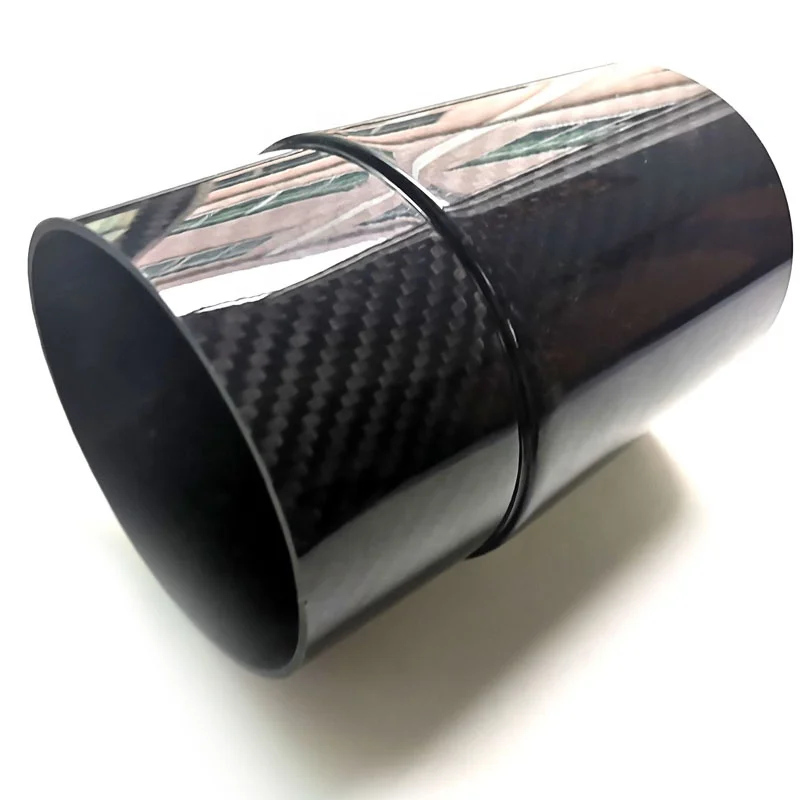

Изготовленный на заказ гоночный автомобиль углеродный выхлопной

- Категория: Выхлопные трубы >>>

- Поставщик: Dongguan,Juli,Composite,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.25 $* | 0.90 $* |

| Aug-18-2025 | 0.80 $* | 0.95 $* |

| Jul-18-2025 | 0.37 $* | 0.19 $* |

| Jun-18-2025 | 0.87 $* | 0.57 $* |

| May-18-2025 | 0.83 $* | 0.96 $* |

| Apr-18-2025 | 0.37 $* | 0.19 $* |

| Mar-18-2025 | 0.41 $* | 0.10 $* |

| Feb-18-2025 | 0.3 $* | 0.71 $* |

| Jan-18-2025 | 0.11 $* | 0.31 $* |

Характеристики

3.5 meter long length carbon fiber tube with 3k twill matt finish use for drone frame and mast pole

Product Description

TECHNICAL DATA SHEET | ||||||||

Manufacturing Method : | Carbon fiber Compression Moulding Process | |||||||

Structure | UW | U = Unidirectional Prepreg | W= Woven Prepreg | |||||

Raw Materials : | Carbon fiber , Epoxy | |||||||

Diameter Range O.D. | make to order | |||||||

Wall Thickness | 0.5 to 10mm | |||||||

Length : | 3.5 Meters Maximum | |||||||

Colors : | RAL Code Or Black | |||||||

Water Absorption | < 1,5w- % | |||||||

Denisty | 1.5g/cm3 | |||||||

FIBER TYPE | HS Carbon | HM Carbon | HM Carbon | |||||

Stiffness | 90 - 100 Gpa | 120- 180 Gpa | ||||||

Bending Strength | >600 Mpa | >500 Mpa | ||||||

Tensile Strength | >650 Mpa | >550 Mpa | ||||||

Denisity | >1.5g/cm3 | >1.5g/cm3 | ||||||

Structure of our Carbon Fiber Tube

TOP THREE FIBER ORIENTATIONS

0 ° ORIENTATION

If a part will only be loaded in one direction it’s ideal to have all the fibers oriented in that direction. Pultruded rod and tubing are examples of a part that contains only 0° fibers

90° ORIENTATION

As previously mentioned, 90° layers are often added to tubes to make them more resistant to buckling and crushing. High concentrations of 90° or “hoop” layers can also be found in pressure vessels.

+/- 45 ° ORIENTATION

45° layers serve different purposes depending on the application. You’ll almost always see a +45° paired adjacent to a -45° layer. This is to keep the laminate “balanced” and from forcefully twisting when loaded.

The Manufacturing Process

There are two Manufacture process to make the carbon fiber exhaust tips , if the design is only fitting together the carbon fiber pipe with stainless part , then using roll warpping process as the the below first line pictures. if the exhaust is irregular shape , then we using compression moulding process to make it. in short. any shape of the carbon fiber parts we can make by the related process .