Машина для прокатки листового металла

US $10000

Поделиться:

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 820122.73 $* | 861128.54 $* |

| Aug-17-2025 | 813230.88 $* | 853892.78 $* |

| Jul-17-2025 | 682286.50 $* | 716400.99 $* |

| Jun-17-2025 | 799446.64 $* | 839418.40 $* |

| May-17-2025 | 696070.62 $* | 730874.95 $* |

| Apr-17-2025 | 785663.78 $* | 824946.96 $* |

| Mar-17-2025 | 778771.49 $* | 817710.10 $* |

| Feb-17-2025 | 771879.12 $* | 810473.89 $* |

| Jan-17-2025 | 764988.57 $* | 803237.36 $* |

Machine Parameters | |

Product | trapezoidal roof tile making ibr and corrugated iron sheet machine |

A.General details | |

Suitable Material | HRB60 or equivalent(PPGI/PPGL/GI/GL) |

Materials thickness | 0.3mm-0.8mm |

Dimension | About 6*1.5*1.8m(L*W*H) , as per the drawing |

Length of the Sheet | can set the length according to your infact need. It is controlled by PLC which can ensure the accuracy of ±1mm. |

Cutting | Automatically stop and cutting when it comes to the set length. |

B.Components Details | |

Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

Main Frame | 350# steel. More stable and no shaking. |

Middle Plate | 18mm. We use thicker plates to ensure stability of our products. |

Forming Steps | 11-20 steps, according to the drawing. |

Shaft Material | Φ70 mm, high grade 45# steel. Treating process: tempering- finish turning, high rigidity, hard to deform. |

Cutting Blade Material | Cr12, hardness HRC60-62. Treating process: heat treatment- plane abrasion- wire electrode cutting. |

C.Electric Components | |

Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

Screen | 7 inch touch screen, easy to operate.Brand Delta or based on your need |

PLC | Delta Brand (Or Panasonic /Siemens ) Well-adapted to various conditions, such as moisture, electromagnetic disturbance. |

Frequency Converter | delta ; It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

Length Measurement Device | Omron, made in Japan. It features with high accuracy and stability. |

Size | 8.7 (L) * 1.65 (W) * 1.2(D) |

Weight | 6.5 T |

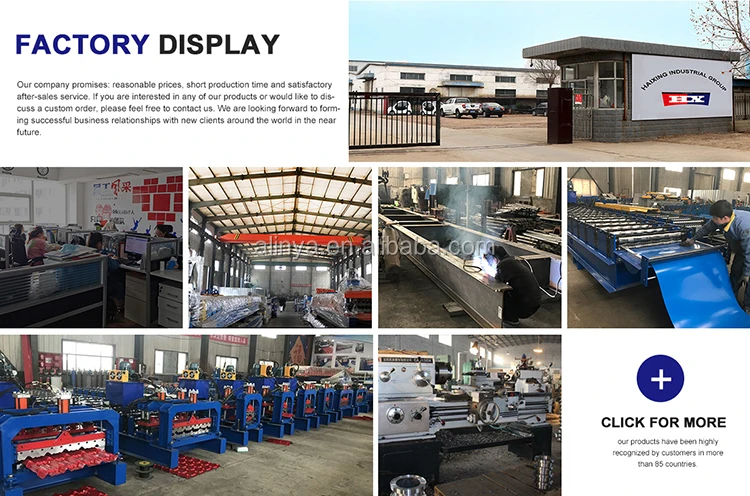

Packaging Details | 1. We have professional technicians for loading.Guaranteed the goods load into container without any damage. 2. Transportation : Machines need one 20 feet container to hold. |

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com