SHR-10 SHR-50 ПВХ пластиковый порошок миксер система автоматизации высокоскоростной смеситель для

- Категория: Пластмассовый смеситель >>>

- Поставщик: Zhangjiagang,Huede,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 3332.66 $* | 3499.40 $* |

| Aug-20-2025 | 3304.72 $* | 3469.14 $* |

| Jul-20-2025 | 2772.51 $* | 2911.72 $* |

| Jun-20-2025 | 3248.44 $* | 3410.38 $* |

| May-20-2025 | 2828.8 $* | 2969.78 $* |

| Apr-20-2025 | 3192.70 $* | 3352.22 $* |

| Mar-20-2025 | 3164.81 $* | 3322.73 $* |

| Feb-20-2025 | 3136.35 $* | 3293.11 $* |

| Jan-20-2025 | 3108.8 $* | 3263.37 $* |

Характеристики

Products Description

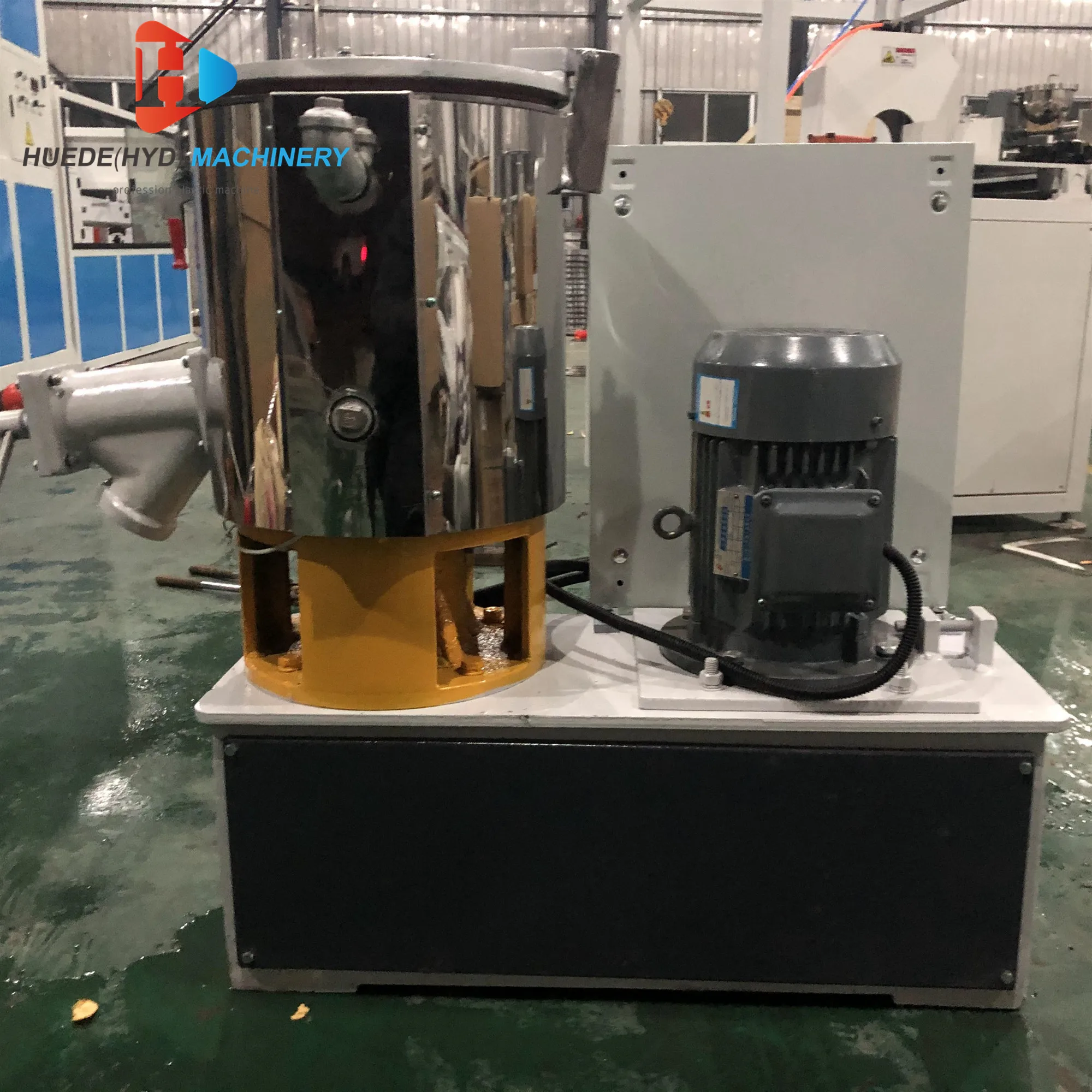

pvc mixer automation system

PVC mixer automation system is applicable for mixing,coloring and drying of various resin such as polypropylene,polyvinyl chloride etc and in the craft of engineering plastics such as ABS,polycarbonate etc before forming and processing as well as in the mixing as phenolic resin.

The high speed mixer for plastic combines heating mixing and cooling mixing craft together.The materials after heating mixing can be got into cool mixer for cooling automatically ,exhaust remaining gases and prevent agglomeration.

Thispvc plastic powder mixer is developed by importing and absorbing advanced technology.By adopting PLC control,it features high automatic level,good mixing result.Heating mixing has such functions as self-friction,and electric heating,The vane has passed the test of dynamic and static equilibrium. The cover adopts double concave-convex seal.Main axis seal adopts special tech of our company,also equipped with pulse dust catching device.Cooling mixer absorbed slowdown tech from overseas,adopts direct slowdown device,overcomes the deadly weakness causing by use of retarder.that makes it running smoothly even more.This machine has come up to the same kind of product level in the world.That is an ideal equipment for producing plates and special-shaped material etc.

1)The pvc mixer automation system is for mixing PVC powder, CACO3 and other addictives. This equipment is widely used in PVC pipe and profile production.

2)Thehigh speed mixer for plastic is composed of high speed mixer (hot mixer), cooling mixer and control cabinet.

3)We use 8mm stainless steel SUS304 for the internal wall construction. It will guarantee the mixer could use for long time under the high friction.

4)The mixing blades are passed the static and dynamic balance testing. And the main shaft adopts fine sealing to prevent from material leakage.

The high speed mixer for plastic combines heating mixing and cooling mixing craft together.The materials after heating mixing can be got into cool mixer for cooling automatically ,exhaust remaining gases and prevent agglomeration.

Thispvc plastic powder mixer is developed by importing and absorbing advanced technology.By adopting PLC control,it features high automatic level,good mixing result.Heating mixing has such functions as self-friction,and electric heating,The vane has passed the test of dynamic and static equilibrium. The cover adopts double concave-convex seal.Main axis seal adopts special tech of our company,also equipped with pulse dust catching device.Cooling mixer absorbed slowdown tech from overseas,adopts direct slowdown device,overcomes the deadly weakness causing by use of retarder.that makes it running smoothly even more.This machine has come up to the same kind of product level in the world.That is an ideal equipment for producing plates and special-shaped material etc.

1)The pvc mixer automation system is for mixing PVC powder, CACO3 and other addictives. This equipment is widely used in PVC pipe and profile production.

2)Thehigh speed mixer for plastic is composed of high speed mixer (hot mixer), cooling mixer and control cabinet.

3)We use 8mm stainless steel SUS304 for the internal wall construction. It will guarantee the mixer could use for long time under the high friction.

4)The mixing blades are passed the static and dynamic balance testing. And the main shaft adopts fine sealing to prevent from material leakage.

Model | Liter | Effective Liter | Power(kw) | Download mode |

SHR-10A | 10 | 8 | 2.2/3.2 | Manual |

SHR-25A | 25 | 20 | 5.5/7.5 | Manual/Pneumatic |

SHR-50A | 50 | 38 | 8/11 | Pneumatic |

SHR-100A | 100 | 78 | 14/22 | Pneumatic |

Customer&Service

All equipment, including parts and components, shall be guaranteed for 24 months, and any problem within the warranty period shall be replaced free of charge (except screw and barrel)

NEW CUSTOMERS:

1.COUNTRIES WITH ENGINEERS(1)$800 per time, excluding food, accommodation and shipping dates, only 10 days.

2. COUNTRIES WITHOUT ENGINEERS

(1) USD 100 per day

(2) Visa free

(3) Round-trip air ticket

(4) Board and lodging

(1) USD 100 per day

(2) Visa free

(3) Round-trip air ticket

(4) Board and lodging

REGULAR CUSTOMERS:

1.If you need on-site installation and commissioning services, you can install the video remotely for free and enjoy a 40%

discount.(According to the new customer charging standards.)

discount.(According to the new customer charging standards.)

Product packaging

FAQ

Q1:Are you trading company or factory?

A1:We are factory,we have our own workshop.

Q2: What's your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: Normally production time is around 10-20 days,the exactly depend on what kind of machine you order. The shipping time is based on your destination port

Q2: What's your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: Normally production time is around 10-20 days,the exactly depend on what kind of machine you order. The shipping time is based on your destination port