Автоматическая высокотемпературная Чугунная Пластина и

- Категория: Filter Press Equipment >>>

- Поставщик: Woking,Environmental,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 10710.17 $* | 11246.15 $* |

| Aug-18-2025 | 10620.43 $* | 11151.25 $* |

| Jul-18-2025 | 8910.20 $* | 9356.45 $* |

| Jun-18-2025 | 10440.58 $* | 10962.20 $* |

| May-18-2025 | 9090.17 $* | 9545.41 $* |

| Apr-18-2025 | 10260.74 $* | 10773.13 $* |

| Mar-18-2025 | 10170.1 $* | 10679.91 $* |

| Feb-18-2025 | 10080.44 $* | 10584.3 $* |

| Jan-18-2025 | 9990.79 $* | 10490.21 $* |

Характеристики

Product Description

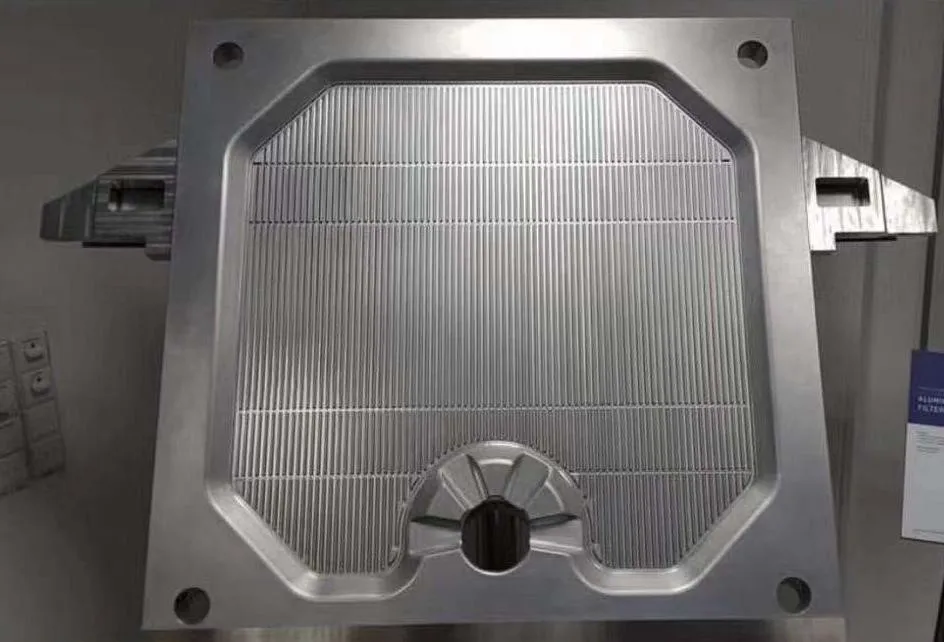

High Temperature Filter Press

1.Filter plate pack is made of cast iron.

2.The filter press structure is processed from cast iron

3.Cotton filter clothes not only endure high temperature, and work with safety & reliability.

4.Can endure higher filtering pressure to get the best dryness.

3.Filter plate can be chamber type or plate/frame type.

4.Also can realize automatic cake discharge to save labors.

2.The filter press structure is processed from cast iron

3.Cotton filter clothes not only endure high temperature, and work with safety & reliability.

4.Can endure higher filtering pressure to get the best dryness.

3.Filter plate can be chamber type or plate/frame type.

4.Also can realize automatic cake discharge to save labors.

Cast Iron Filter Press:

1. It's mainly suitable for material over 100 ℃.

2. It has strong strength, so can endure higher filtering pressure to ensure the lowest cake moisture.

3. Suggest automatic cake discharging since the plates are too heavy.

4. Because of the limitation of cast iron, it only can be used for neutral liquids. It can not be used for solid-liquid separation of acid, alkalies, and corrosive materials.

2. It has strong strength, so can endure higher filtering pressure to ensure the lowest cake moisture.

3. Suggest automatic cake discharging since the plates are too heavy.

4. Because of the limitation of cast iron, it only can be used for neutral liquids. It can not be used for solid-liquid separation of acid, alkalies, and corrosive materials.

Working principle of Filter Press:

1. Slurry is pumped into the filter press. The solids are distributed evenly on the filter cloths during the feed (fill) cycle.

2. Solids begin to build on the filter cloth, trapping the ensuing particles and building a filter cake. The filter cake acts as a depth filter for solid/liquid separation. Filtrate exits the plates through the corner ports into the manifold.

3. When the correct valves in the manifold are open, the filtrate exits the press through the filtrate outlet. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of filter cake.

4. Once the chambers are full, the fill cycle is complete and the filter press is ready to be emptied.

2. Solids begin to build on the filter cloth, trapping the ensuing particles and building a filter cake. The filter cake acts as a depth filter for solid/liquid separation. Filtrate exits the plates through the corner ports into the manifold.

3. When the correct valves in the manifold are open, the filtrate exits the press through the filtrate outlet. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of filter cake.

4. Once the chambers are full, the fill cycle is complete and the filter press is ready to be emptied.

Optional facility

Case

Sand Making Industry

Kaolin Industry

Mining Industry

Tunneling Industry

Stone Industry

Potassium Feldspar

Coal Washing

Ceramic Tile Industry

Municipal slurry

Похожие товары

Фильтрующая пресс-машина для очистки сточных вод с чернилами

US $6500-$7000

Фильтрующий пресс используется для очистки сточных вод бетономешалки

US $35000-$112000