Frp лист текстура панели прямой производитель Xps пены изоляционные Листы доска Сэндвич Композитная

- Категория: Other Fiberglass Products >>>

- Поставщик: Hebei,Yukuo,Environmental,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.11 $* | 0.2 $* |

| Aug-18-2025 | 0.34 $* | 0.31 $* |

| Jul-18-2025 | 0.85 $* | 0.92 $* |

| Jun-18-2025 | 0.69 $* | 0.36 $* |

| May-18-2025 | 0.90 $* | 0.28 $* |

| Apr-18-2025 | 0.9 $* | 0.88 $* |

| Mar-18-2025 | 0.80 $* | 0.38 $* |

| Feb-18-2025 | 0.27 $* | 0.94 $* |

| Jan-18-2025 | 0.24 $* | 0.98 $* |

Характеристики

Frp Leaf Texture Panel Direct Manufacturer Xps Rigid Foam Insulation Sheets Board Frp Sandwich Composite Panel

Product Description

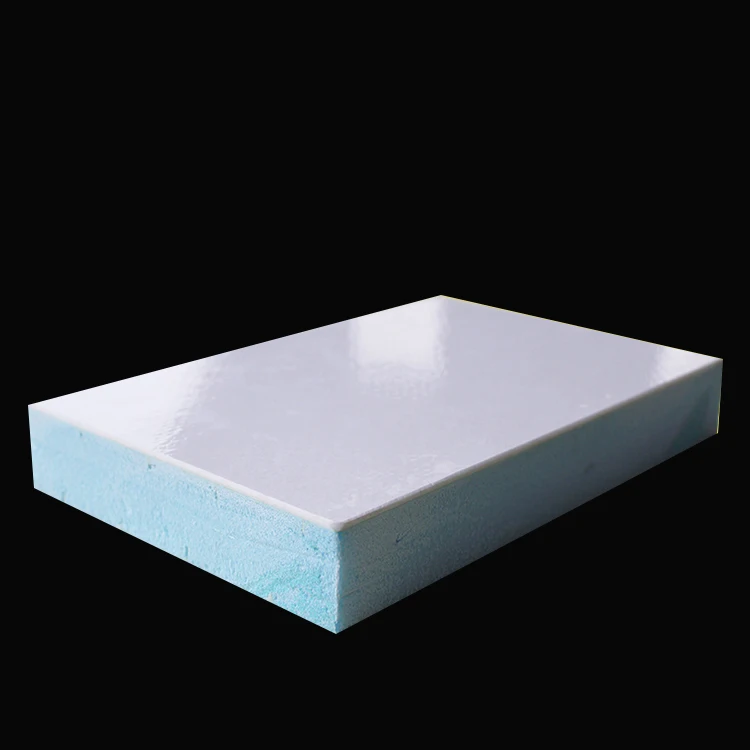

The FRP fiberglass sandwich panel is a new kind of high-quality environmental-friendly product, which is made of heat-cured gel coat, synthetic resin and fiberglass. And it's widely used in high-grade automobiles, refrigerator truck compartments and purification, medical treatment, food hygiene,food processing facilities, restaurants, commercial buildings and wash facilities and other projects.

Specification

FRP XPS sandwich panel is fiber reinforced plastic as cover sheets and high density XPS foam (also known as Extruded polystyrene) as the core material. XPS as the core insulation material has a unique combination of physical and chemical characteristics which other insulation materials are unable to match. FRP XPS Sandwich panel is used for building field, it has good thermal insulation feature.

Model Number | NGPF-97 |

Application | Refrigerated truck bodies, caravans |

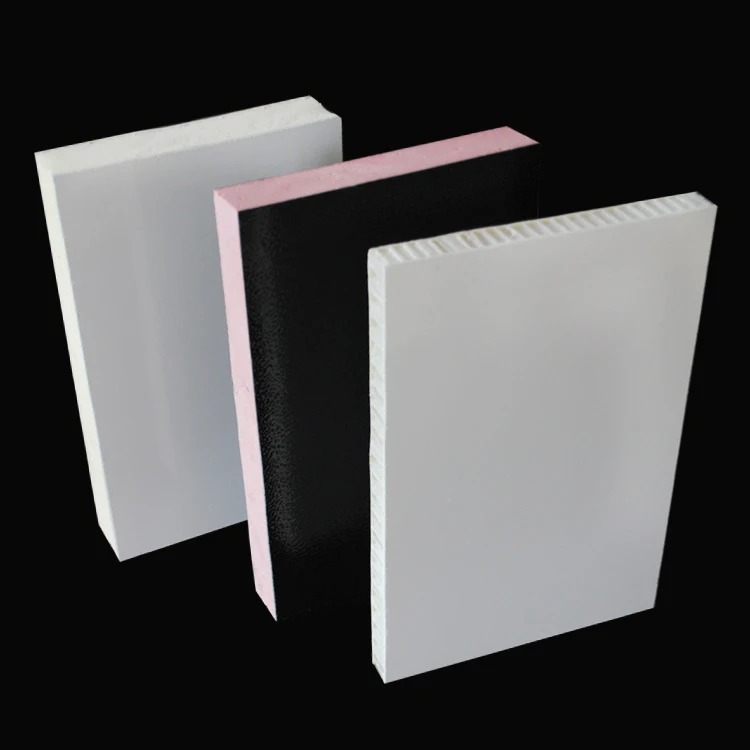

Surface Treatment | High Glossy/Woven Roving/Chopped Strand Mat/Matte/Embossed, etc |

Technique | FRP Continuous Production |

Processing Service | Bending, Decoiling, Moulding, Welding, Punching, Cutting |

Color | White or customized |

Material | FRP sheet and core material |

Cover Materials | Fiberglass Reinforced Polyester (FRP) |

Core material | XPS foam(also known as Extruded polystyrene) |

FRP Thickness | 1mm-3mm |

Core Thickness | 10mm-100mm |

Max. Width | 2500mm |

Max. Length | 12000mm |

Panel Material | Pebbled Texture Panel/Smooth Panel/FRP Leaf Texture Panel |

The above mentioned panels can be combined with the froth, gypsum, polywood, aluminium, PP, XPS, honeycomb. The sandwich panel is a more strengthen, better rigidity panel. The sandwich panels will be easier to install, the installation efficiency will be improved greatly, furthermore, the requirement of wall coarseness will be reduced.

Product Details

Features of FRP fiberglass reinforced plastic XPS extrude polystyrene sandwich panel

1. FRP XPS sandwich panel is bonding of two outer layers of high gloss FRP sheets under the pressure to an inner core of insulation XPS.2. Weather resistance: FRP is a kind of thermosetting high polymer with good thermal stability. Its work temperature range is between -70 centigrade to 100 centigrade.

3. Shock resistance: FRP sheet contains interlaced glass fiber, which increases the shock resistance greatly and avoids fracture under collision of stones and hails.

4. Corrosion resistance: The outside surface has a layer of high quality gel coat, which gives the product a good chemical stability to stand the corrosion of atmosphere, water and ordinary acid, alkaline and salt. So that it is very suitable to be used in placesnear the sea or areas with corrosion.

Application

Application of FRP fiberglass reinforced plastic XPS extrude polystyrene sandwich panel

FRP XPS Sandwich panel is used for building field.

1)Temporary offices,dormitories,warehouse and workshop in construction sites and in municipal works and residential resettlements

2) Temporary commercial housings in the cities,such as exhibition halls,shopping centers,offices and other housings for exhibition and sports

3) Holiday inns or container house,leisure villas and holiday homes in tourist spots.

4) Temporary houses used in large-scale fieldwork,such as exploiting energy sources and making tunnels,warehouse

5) Temporary houses in military field and temporary housings in earthquake,fire, hurricane and flood disaster-affected areas

6) large area suspended ceiling,separation of steel structure workshop,suspended ceiling,wall body and air purification room. Refrigerated truck bodies, caravans.

1)Temporary offices,dormitories,warehouse and workshop in construction sites and in municipal works and residential resettlements

2) Temporary commercial housings in the cities,such as exhibition halls,shopping centers,offices and other housings for exhibition and sports

3) Holiday inns or container house,leisure villas and holiday homes in tourist spots.

4) Temporary houses used in large-scale fieldwork,such as exploiting energy sources and making tunnels,warehouse

5) Temporary houses in military field and temporary housings in earthquake,fire, hurricane and flood disaster-affected areas

6) large area suspended ceiling,separation of steel structure workshop,suspended ceiling,wall body and air purification room. Refrigerated truck bodies, caravans.

Packing & Delivery

Packing Details: FRP fiberglass reinforced plastic XPS extrude polystyrene sandwich panel are well packaged with all the necessary materials. Bulk, Carton box, wooden pallet, steel pallet or as per customers' requirements.

Delivery Details: 5-30days

Package | 1. Plywood Pallet 2. Plywood case 3. Customized | |

Delivery | 1. Samples: 2-3 days if we have in stock; 2. Mass production: 15 working days 3. Delivery terms: EXW, FOB, CIF, DDP all can be accepted | |

Corrosion Resistance PU XPS FRP Fiberglass Sandwich Panel | ||

Company Profile

Hebei Yukuo FRP Manufacturing Co., Ltd always regards product quality as the foundation of enterprise development. Over the years, our company has carried out scientific and standardized management in strict accordance with the modern enterprise model. According to the customers feedbacks and based on global market we have set up a series of services and tactics. Based on science and technology, we have innovated varied products and achieved domestic and worldwide fame. The company has perfect testing equipments, strong technical support, providing customers with quality services. Our products are sold all over the world, and deeply trusted by users!

FAQ

Q: Are you a trading or a manufactory?

A: We are one of largest FRP manufacturer in China, Yukuo group have two separated factories in two different places.

Q: Can your factory provide customized services?

A: Yes,we can. From small parts to large machine, we can provide all kinds of customized services.

Q: Can you do OEM?

A: Yes. We can offer OEM & ODM.

Q: I am interested in your products,can I have sample for free?

A: We could supply a few pieces of free samples.

Q: What is your payment terms?

A: Normally,50% as the deposit first by T/T,the rest 50% will be paid before shipping by T/T.

A: Normally,50% as the deposit first by T/T,the rest 50% will be paid before shipping by T/T.

Q: Can you provide some videos where we can see the line producing?

A: Yes,we can.

Q: What about the delivery?

A: It depends on the product performance and quantity you need.

Q: How about after-sales service?

A: Most of the products have 1 year free warranty, Lifetime technical service support.For more details, please contact us any time.

Q: How can I install the productime line and get a commissioning?

A: We may send our engineer for installation and commissioning, but relevant cost will be paid by you. For more quetions,please do not hesitate to contact us!

Похожие товары

Стекловолоконные обрезки/Отходная пряжа для гипсокартона

US $0.70-$0.80

Гибридные ткани из базальтового волокна

US $3.80-$4.00

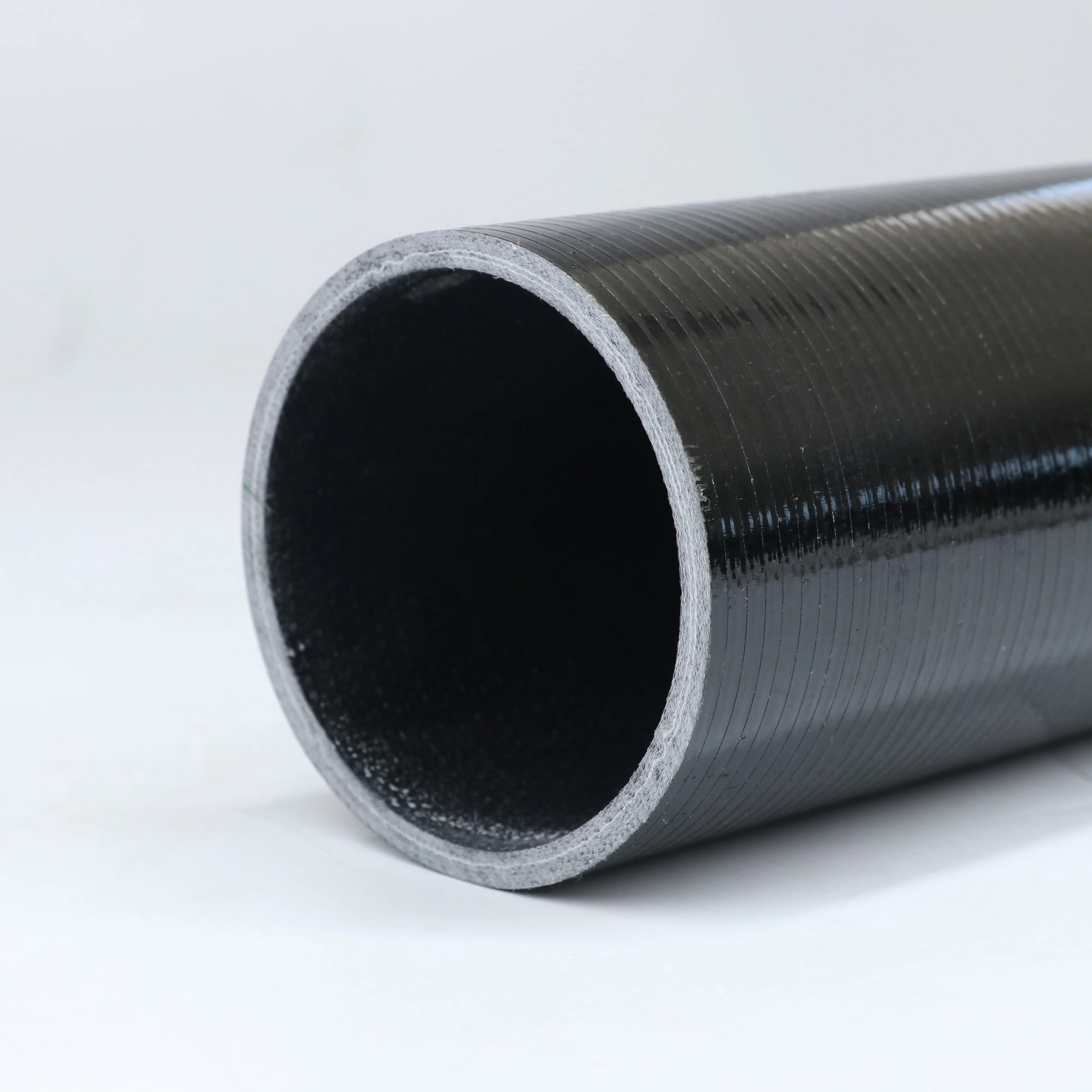

Высокопрочная термостойкая Стекловолоконная труба/столб/труба

US $19.00-$24.00