Индукционная плавильная печь горизонтальная машина для непрерывного литья под ключ CCM линия заготовки стальная установка

- Категория: >>>

- Поставщик: Astec,Equipments,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-18-2025 | 253999.43 $* | 259079.49 $* |

| Jul-18-2025 | 205999.91 $* | 210119.30 $* |

| Jun-18-2025 | 249999.3 $* | 254999.42 $* |

| May-18-2025 | 247999.80 $* | 252959.38 $* |

| Apr-18-2025 | 197999.0 $* | 201959.38 $* |

| Mar-18-2025 | 243999.18 $* | 248879.68 $* |

| Feb-18-2025 | 241999.92 $* | 246839.52 $* |

| Jan-18-2025 | 239999.3 $* | 244799.10 $* |

Характеристики

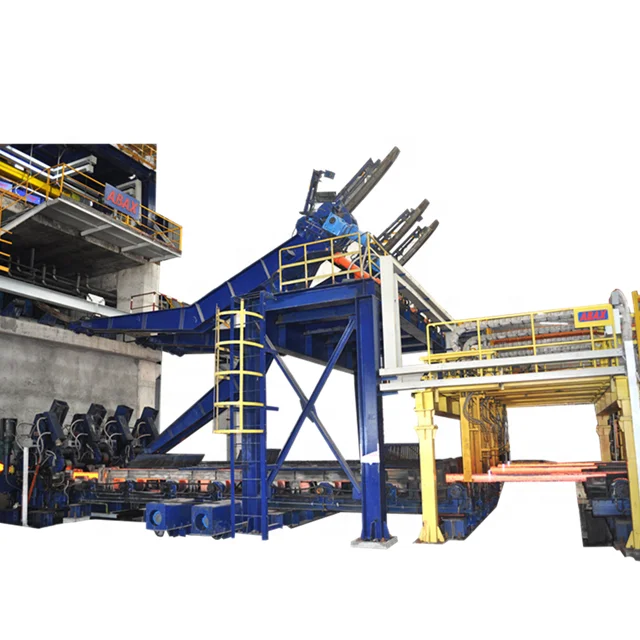

HOW TO MAKE STEEL BILLET IN CONTINUOUS CASTING MACHINE | STEEL BILLET MAKING PROCESSING |

Steel Ladle and Crane | High temperature resistant metallurgical crane lift full loaded steel ladle onto billet casting Platform |

↓ | |

Steel Ladle Turret or Ladle Car | Innovative design for holding the pouring ladle. Cheapest way is to put the bottom pouring ladle on the supporting steel frame |

↓ | |

Tundish or Tundish Car | Non-radioactive mould level control of ABAX STEEL technology Safe Operation Worker Protection |

↓ | |

Molding Crystallizer Mould Jacket with protection housing | Mould Electromagnetic Stirrers for SBQ grades |

↓ | |

Oscillator | Quality tracking system |

↓ | |

Secondary Cooling and Billet Guiding Segment | Proven Level-2 process control |

↓ | |

Withdrawal Straightening Unit | Highest productivity with ABAX XXL technology |

↓ | |

Rigid Dummy Bar and Dummy Bar Storage Device | High degree of automation Easy control by pushing button |

↓ | |

Roller Table before Cutting | |

↓ | |

Torch Cutting Machine (TCM) | |

↓ | |

Roller Table after Cutting | |

↓ | |

Terminal Roller Table | |

↓ | |

Cross Transfer Zone Billet Pusher | |

↓ | |

Beam Cooling Bed Cooling Zone |

COPPER MOULD TUBES MANUFACTURER -- ABAX STEEL

Henan COBAX Equipments Co., Ltd. ( hereinafter referred to as COBAX) is a wholly-owned factory invested and established by European ABAX STEEL group in China. It has two plant areas of CNC mechanical processing center and electroplating production line. It is a professional manufacturer with European technology and production technology, whose main products are continuous casting mold copper tube and continuous casting machine equipment.

COBAX adopts the advanced technology of Italian foundry industry todesign and produce special mould copper tubes for continuous casting machine. The designed output of the plant can reach 20000 pieces a year. The estimated annual output value is about 100 million USD. The output value of other CCM spare parts is about 50 million USD, and the total output value is about 150 million USD.

COBAX R & D team has 5 European engineers and 10 overseas project management engineers, all of them have graduate degree or above, and 5 have intermediate and senior engineer titles. We have the strength to create high-quality European process mould copper pipes for our customers.

ABAX STEEL began to produce mold copper tubes in 2002 and has since developed into a global supplier of mold copper tubes and plates for continuous casting. We regularly supply 120 customers in 20 different countries.

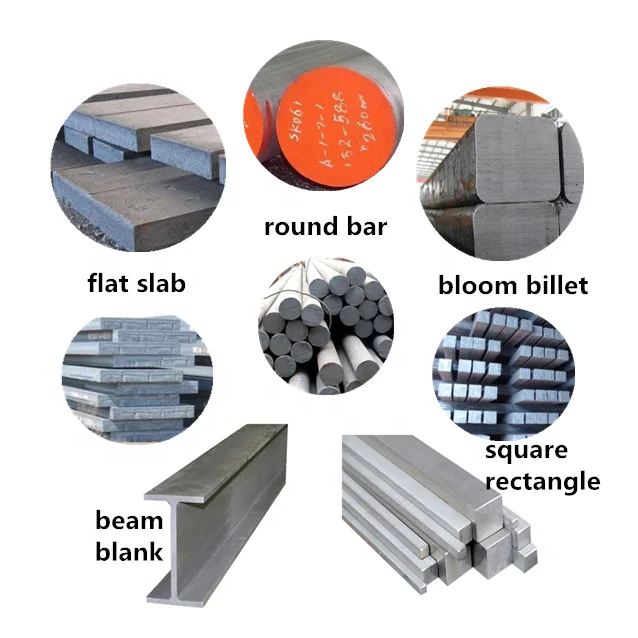

ABAX STEEL is a European engineering company, which provides professional turnkey projects for steel-making enterprises at home and abroad. Relying on Danieli and Voest Alpine technology and combining with specific requirements of steel plants, ABAX STEEL designs continuous casting and rolling high-speed line and automatic control system for steel production. The main business focuses on the design and production of bloom, billet, beam blank, flat billet, round billet and non-standard billet caster and spare parts field. ABAX STEEL developed ultra-high speed continuous casting mold, quality tracking system, safe liquid level detection and control technology in the world.

So far, ABAXSTEEL has successfully handed over more than 30 turnkey projects of billet caster in the world. ABAX STEEL is your best partner in steelmaking field!