Машина Для Брикетирования Угольной Пыли/машина для брикетирования шаров минерального угля/машина порошка угля

- Категория: Машина для изготовления брикетов >>>

- Поставщик: Zhengzhou,Huayu,Briquette,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 2142.11 $* | 2249.68 $* |

| Aug-18-2025 | 2124.0 $* | 2230.44 $* |

| Jul-18-2025 | 1782.51 $* | 1871.63 $* |

| Jun-18-2025 | 2088.24 $* | 2192.72 $* |

| May-18-2025 | 1818.31 $* | 1909.9 $* |

| Apr-18-2025 | 2052.71 $* | 2155.38 $* |

| Mar-18-2025 | 2034.63 $* | 2136.45 $* |

| Feb-18-2025 | 2016.14 $* | 2117.69 $* |

| Jan-18-2025 | 1998.96 $* | 2098.60 $* |

Характеристики

Ball press machine is used for making coal fines, coke fines, charcoal powder, carbon black, carbon, salt, chemical salt, iron ore fines, silicon carbide, mineral powder, metal dust, cast iron dust, mill scale, manganese ore fines, fluorite powder, gypsum powder, ferrosilicon powder, and phosphor gypsum powder, nickel alloy, blast furnace ash, converter dust, coal gangue, Kaolin clay, MgO, NPK, graphite, oil shale, potash fertilizer, urea fertilizer, sea sand powder etc. Into briquettes. These briquettes ball can be designed of oval shape, egg shape, pillow shape etc. This ball press machine is widely used in coal industry, metallurgy industry, chemical industry etc.

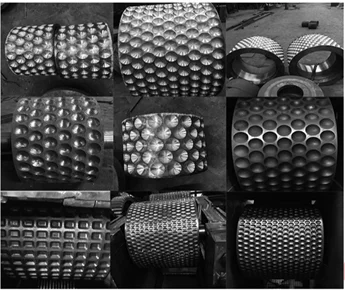

1. The overview picture of the machine

2.\tThe structure picture of the machine

3.\tThe working principle of the machine

After putting powdery materials which mix proportional binder into the machine inlet, the motor drives the two roller skins to apply pressure to press them into balls or other forms.

Different roller skins make different shapes of products.

main technical parameter | ||||||||||||||||||

model | HG-290 | HG-360 | HG-430 | HG-520 | HG-670 | HG-750 | HG-800 | HG-850 | HG-1000 | |||||||||

yield(t/h) | 1~2 | 2~4 | 4~8 | 6~10 | 10~15 | 15~18 | 18~20 | 20~25 | 25~35 | |||||||||

roll width(mm) | 200 | 250 | 280 | 300 | 330 | 400 | 420 | 450 | 570 | |||||||||

roll diameter(mm) | 290 | 360 | 430 | 520 | 670 | 750 | 800 | 850 | 1000 | |||||||||

roll material | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | |||||||||

alloy steel | alloy steel | alloy steel | alloy steel | alloy steel | alloy steel | alloy steel | alloy steel | alloy steel | ||||||||||

power(kw) | 5.5 | 7.5 | 11~15 | 22 | 37 | 45 | 55-75 | 75 | 110 | |||||||||

spindle speed(r/m) | 13 | 13 | 13 | 12 | 12 | 12 | 10 | 10 | 10 | |||||||||

reducer | ZQ350 | ZQ350 | ZQ350 | ZQ500 | ZQ650 | ZQ750 | ZQ850 | ZQ1000 | ZQ1250 | |||||||||

pressure form | oblique iron pressure | |||||||||||||||||

disc spring pressure | ||||||||||||||||||

hydraulic constant pressure | ||||||||||||||||||

structure type | double rollers single pressure | |||||||||||||||||

four rollers double pressure | ||||||||||||||||||

ball size | user-defined | |||||||||||||||||

In addition, there are other models which have different yield for you to choose from.

Many kinds of raw materials can be put into the briquette machine, which include charcoal, iron, coal powder, etc.

The fluorite briquette making machine can output many shapes of finished products by different roller skins, and the size of finished products can also be customized as your requirements.

* Apart from coal powder, many other materials can be compressed

* High yield, high efficiency and non-pollution

* More durable because rollers are made of 65Mn

* Easy change parts and maintenance because the machine is assembled

Our company has more than 100 experienced workers and a complete set of production line which includes assembling, pressing, roller processing, case processing, and other workshops.

The follow pictures are our factory and workshops.

Please trust us. We have the best factory price and we have the enough ability and strength to manufacture high-quality machines in a timely and efficient manner.

Packing: We can install machines in the factory first or send the installation instructions to assist you.

Delivery: We usually deliver machines by One Touch of Alibaba Company in order to guarantee the delivery time and the quality of machines. We can also use other ways as your requirements.

Pre-Sales Service

* Inquiry and consulting support swiftly

* View our factory

* Using your mailed sample to test the machine

After-Sales Service

* Training how to install the machine and how to use the machine

* Engineers available to service machinery overseas

If you have any questions about the machine or our company, please contact us freely. We will response swiftly and do our best to meet your demand.