Машина для сушки опилок с горячим воздухом 200-800 кг в

- Категория: Печь с горячим воздухом >>>

- Поставщик: Zhengzhou,Huayu,Briquette,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 2927.25 $* | 3073.52 $* |

| Aug-18-2025 | 2903.99 $* | 3048.51 $* |

| Jul-18-2025 | 2435.31 $* | 2557.79 $* |

| Jun-18-2025 | 2854.52 $* | 2997.60 $* |

| May-18-2025 | 2485.18 $* | 2609.34 $* |

| Apr-18-2025 | 2804.97 $* | 2944.61 $* |

| Mar-18-2025 | 2780.28 $* | 2919.36 $* |

| Feb-18-2025 | 2755.81 $* | 2893.97 $* |

| Jan-18-2025 | 2731.62 $* | 2868.20 $* |

Характеристики

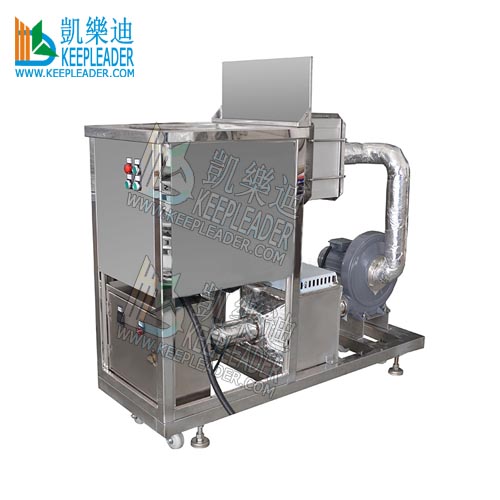

Airflow Dryer Machine

The airflow dryer is a hot air pulse dryer, also known as a hot air duct dryer. The advantage of this dryer is direct heating, fast drying, foldable installation and space saving. The airflow dryer is to let the moist raw materials mix with the high-temperature airflow, and the water is separated from the raw materials through the separator.

This dryer is suitable for drying materials of moisture 30~60%. The dryer is equipped with two fuel boilers, inlet, steel pipe, exhaust blower (fan), air lock and cyclone. Wet materials are put into the hopper. The fuel boiler generates hot air which mixes with wet materials and then is sucked into the pipes by the exhaust blower (fan) quickly. And then hot air is flowing and going though the curving pipes and buffer (drying chamber) of dryer, thus wet materials is finished to dry, and the dried materials are discharged from the outlet with air lock. This wood dryer reduces the moisture to 8~12% with the advantages of low cost consumption and high efficiency.

1. Airflow Dryer Machine

2. The working principle of the machine

How it works?

1. Raw materials should be sawdust, suitable for drying the moisture from 20-50% to 8-12% ;

2. Diameter of raw materials: >3mm & < 5mm;

3. Temperature of Hot Air: 180-250 ;

4. Working principle: The stoves (boilers) generate hot air, then through the fan to dry the materials;

5. This wood dryer reduces the moisture to 8-12% with the advantages of lower cost consumption and high efficiency;

6. The wood dryer is equipped with one fuel boiler, inlet, steel pipe, exhaust blower (fan), cyclone.Wet materials are input into the hopper. The fuel boiler generates hot air which mixes with wet materials and then is sucked into the pipes by the exhaust blower (fan) quickly. And then hot air is flowing and going though the curving pipes and buffer (drying chamber) of dryer, thus wet materials is finished to dry, and the dried materials are expelled out by the exhaust blower (fan).

Model | QH219*4 | QH330*4 | QH550*4 | QH650*4 | QH750*4 | QH1000*4 |

Motor power(kw) | 18.5 | 22 | 30 | 37 | 45 | 55 |

drying capacity(t/h) | 0.2 | 0.3 | 0.4 | 0.5 | 0.7 | 1.0 |

1. The airflow dryer has high thermal efficiency

2. The airflow dryer has a wide application range, high output and large precipitation range;

3.the structure is simple, the station area is small, and the investment and maintenance costs are low.

Our company has more than 100 experienced workers and a complete set of production line which includes assembling, pressing, roller processing, case processing, and other workshops.

The follow pictures are our factory and workshops.

Please trust us. We have the best factory price and we have the enough ability and strength to manufacture high-quality machines in a timely and efficient manner.

Packing: We can install machines in the factory first or send the installation instructions to assist you.

Delivery: We usually deliver machines by One Touch of Alibaba Company in order to guarantee the delivery time and the quality of machines. We can also use other ways as your requirements.

Pre-Sales Service

* Inquiry and consulting support swiftly

* View our factory

* Using your mailed sample to test the machine

After-Sales Service

* Training how to install the machine and how to use the machine

* Engineers available to service machinery overseas

If you have any questions about the machine or our company, please contact us freely. We will response swiftly and do our best to meet your demand.