Profibus Dp протокол модуль интегральная плата для привода

- Категория: Запчасти и аксессуары для инструментов >>>

- Поставщик: Microcyber,Corporation

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-20-2025 | 113.10 $* | 115.13 $* |

| Jul-20-2025 | 92.41 $* | 94.72 $* |

| Jun-20-2025 | 111.78 $* | 113.69 $* |

| May-20-2025 | 110.39 $* | 112.76 $* |

| Apr-20-2025 | 88.22 $* | 90.39 $* |

| Mar-20-2025 | 109.35 $* | 111.25 $* |

| Feb-20-2025 | 108.8 $* | 110.64 $* |

| Jan-20-2025 | 107.40 $* | 109.75 $* |

Характеристики

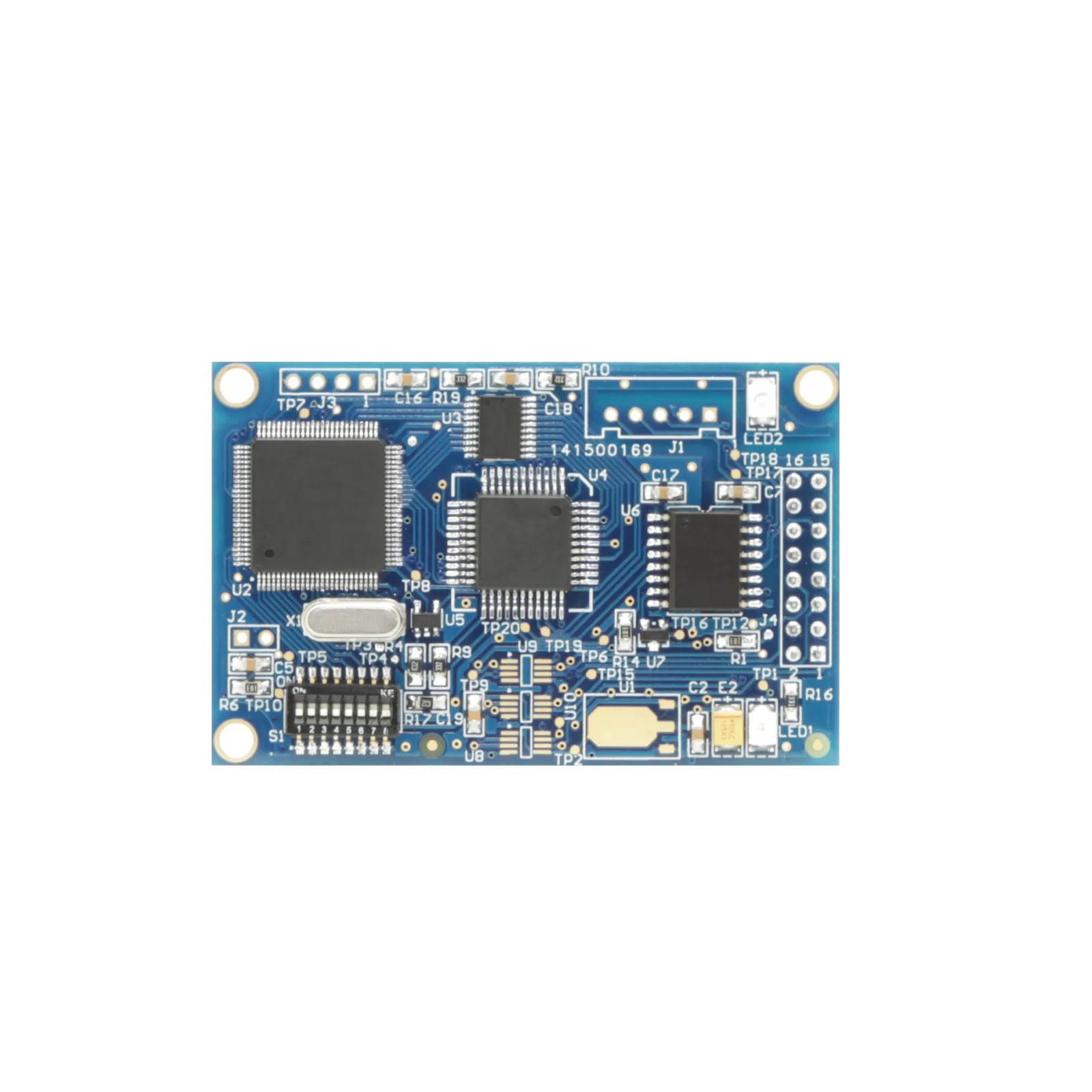

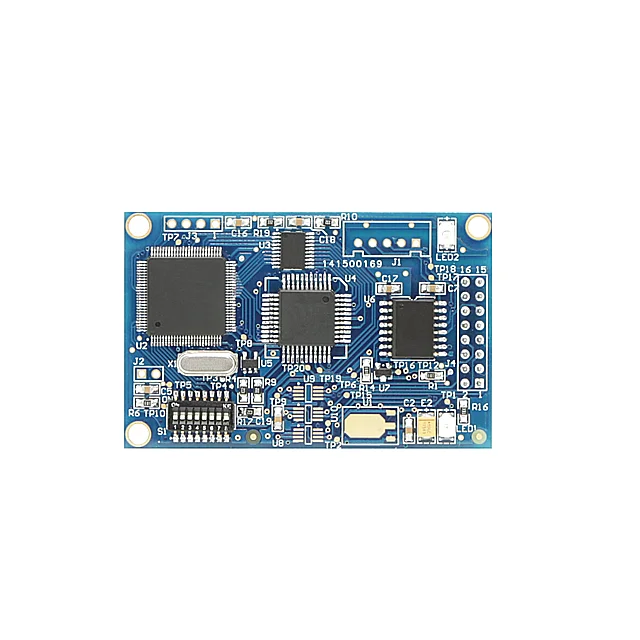

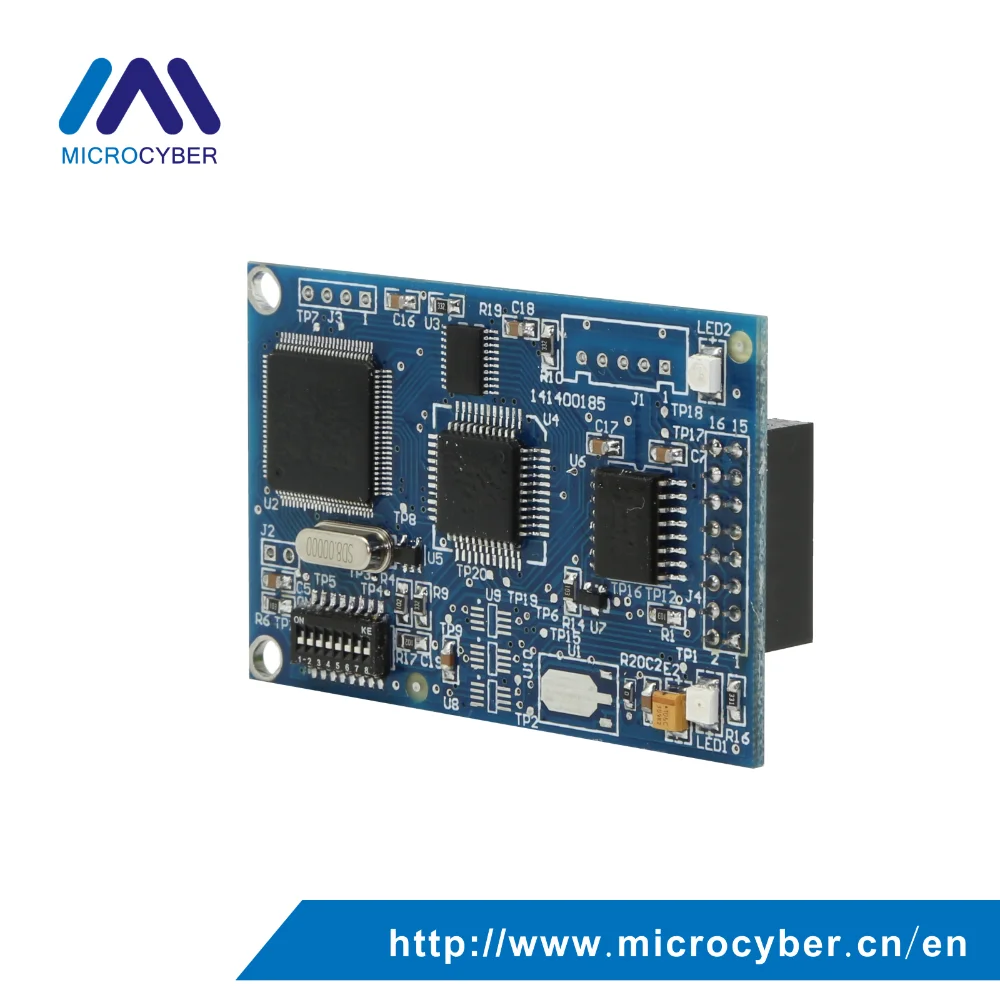

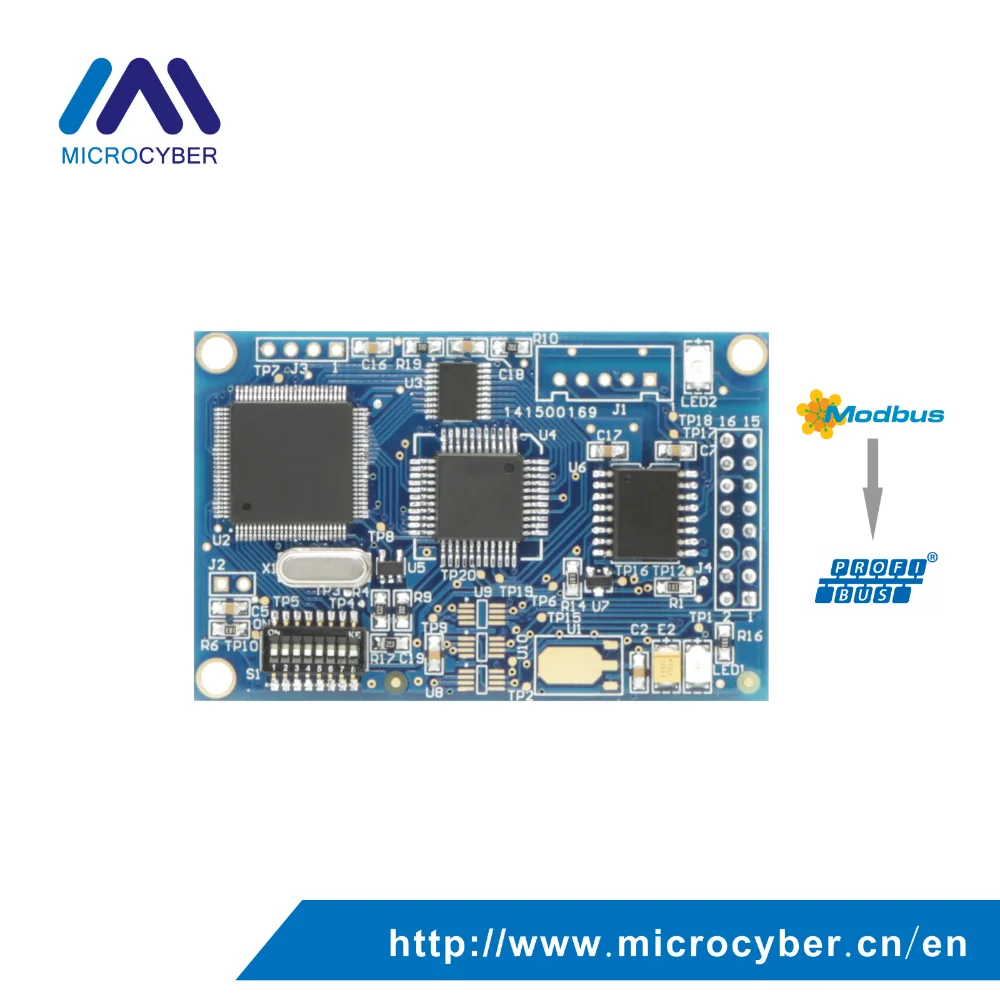

Modbus-DP built-in module realizes the connection from Modbus RTU device to PROFIBUS DP network .It realizes the conversion function from MODBUS Protocol to PROFIBUS DP Protocol. Only by simply operating Modbus configuration tool, the users can realize connection from Modbus RTU device to PROFIBUS DP network.

M0306 module works with DIP16 2.54mm standard interface, 3.3 V power supply, Modbus communication indicating light to quick diagnosis the device status. It uses simple convenience

Combining with the features of high reliability and high flexibility, M0306 module is an ideal choice for user to develop OEM devices with PROFIBUS DP protocol.

Basic Parameter | ||

Power | VCC(MCU power):5.0V 120mA / 3.3V 100mA | |

DP bus baud rate | Baud rate self- adaption:9.6K~12Mbps | |

Protocol before transition | Modbus GB/Z 19582.1-2004 | |

Protocol after transition | Profibus DP GB/T 20540.1~.6-2006 | |

DP max input data | Max Input Bytes ≤ 244 Bytes | |

DP max output data | Max Output Bytes ≤ 244 Bytes | |

DP max total input and output data | Input Bytes + Output Bytes ≤ 360 Bytes | |

max user data | Max User Data Bytes ≤ 200 Bytes | |

Max IO configuration data | Max IO Configuration Data Bytes ≤ 20 Bytes | |

Temperature range | -40℃ ~ +85℃ | |

Humidity range | 5 ~ 95%RH | |

Start time | ≤ 5s | |

Weight | 14 g | |

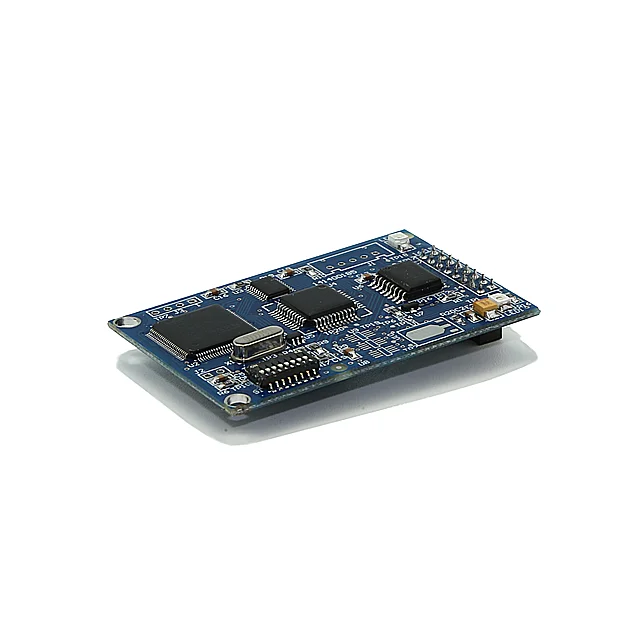

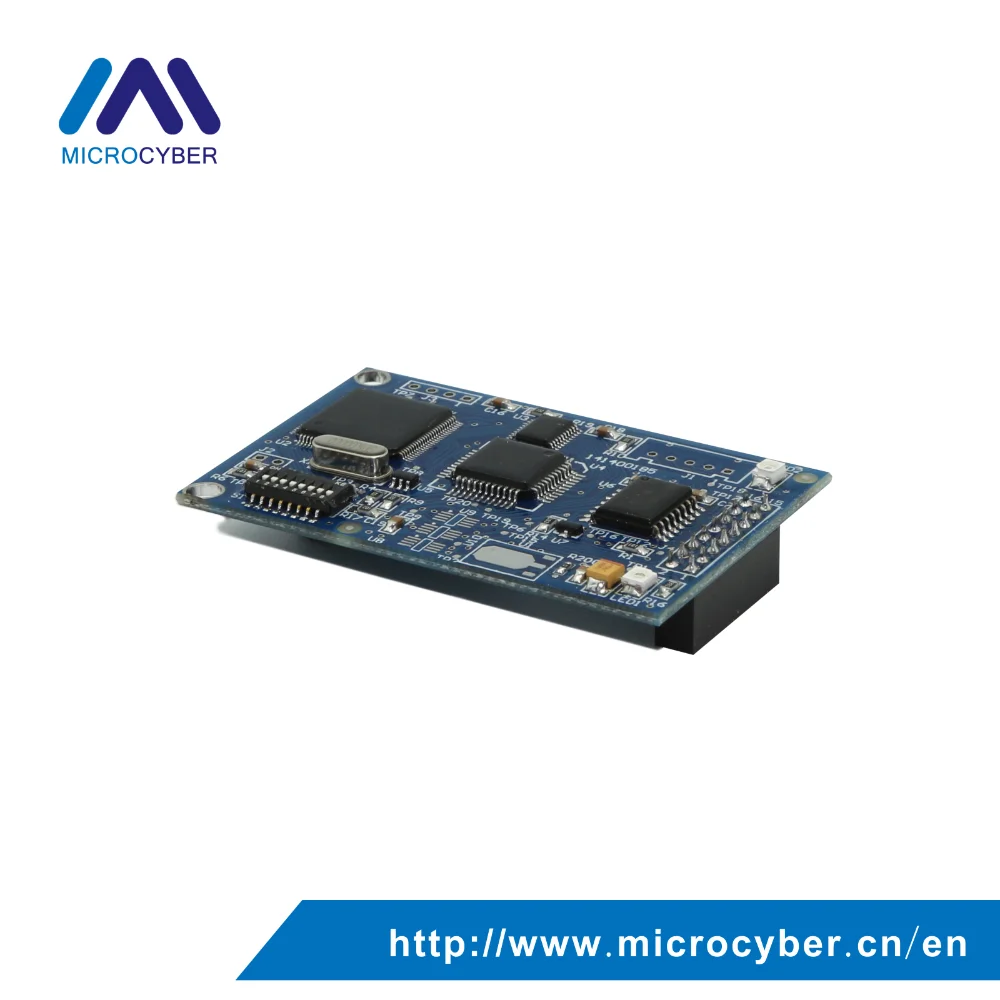

Dimension (L×W×H) | 65×42×14 mm | |

Electromagnetic compatibility | GB/T 18268.1 | |

Noise interference | EN 61131-2:2003 | |

Support Modbus Function Code | ||

01H | read coil state | |

02H | read input state | |

03H | Read holding register | |

04H | Read input register | |

05H | Set single coil | |

06H | Preset single register | |

0FH | Force various coils | |

10H | Preset various regsters | |

The user interface provides the module with one signal isolated DC power supply, serial interface between the two boards, as well as indicator lights and other functions. The specific description is shown in table Table 2.1.

Pin | I/O | Description | Pin | I/O | Description |

1 | I | VCC(5.0V / 3.3V DC) | 2 | O | VCC grounding |

3 | I | CPU Reset, Low Valid | 4 | I/O | Reserved |

5 | O | CPU serial data transmission | 6 | I/O | Reserved |

7 | I/O | Reserved | 8 | I | CPU serial data acceptance |

9 | O | Connect No.4 pin of PROFIBUS DP D type socket | 10 | O | DP communication state indication |

11 | I/O | Connect No.3 pin of PROFIBUS DP D type socket | 12 | I/O | Connect No.8 pin of PROFIBUS DP D type socket |

13 | I/O | Reserved | 14 | I/O | Reserved |

15 | I | 5V isolation power supply | 16 | O | 0V(isolation power supply grounding, isolated with GND) |

No. | Name | Description |

1 | 1 | If ON,address+1,if not,addres+0. |

2 | 2 | If ON,address +2,if not,address +0. |

3 | 4 | If ON,address +4,if not,address +0. |

4 | 8 | If ON,address +8,if not,address +0. |

5 | 16 | If ON,address +16,if not,address +0. |

6 | 32 | If ON,address +32,if not,address +0. |

7 | 64 | If ON,address +64,if not,address +0. |

8 | M | M0306 working mode setting,ON is configuration mode, and OFF is normal working mode. |

Q: How are modules configured and used?

2) Through the TTL to the serial port device, connect the module to computer serial port;

Q: Can you provided OEM service?