Черная офсетная печать водяных чернил/Водяные чернила 1

- Категория: Printing Inks >>>

- Поставщик: Guangzhou,Print,Area,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 105.75 $* | 110.24 $* |

| Aug-15-2025 | 104.55 $* | 109.83 $* |

| Jul-15-2025 | 87.24 $* | 91.55 $* |

| Jun-15-2025 | 102.84 $* | 107.39 $* |

| May-15-2025 | 89.5 $* | 93.49 $* |

| Apr-15-2025 | 100.94 $* | 105.93 $* |

| Mar-15-2025 | 99.83 $* | 104.61 $* |

| Feb-15-2025 | 99.97 $* | 104.30 $* |

| Jan-15-2025 | 98.9 $* | 103.73 $* |

Характеристики

Product Description

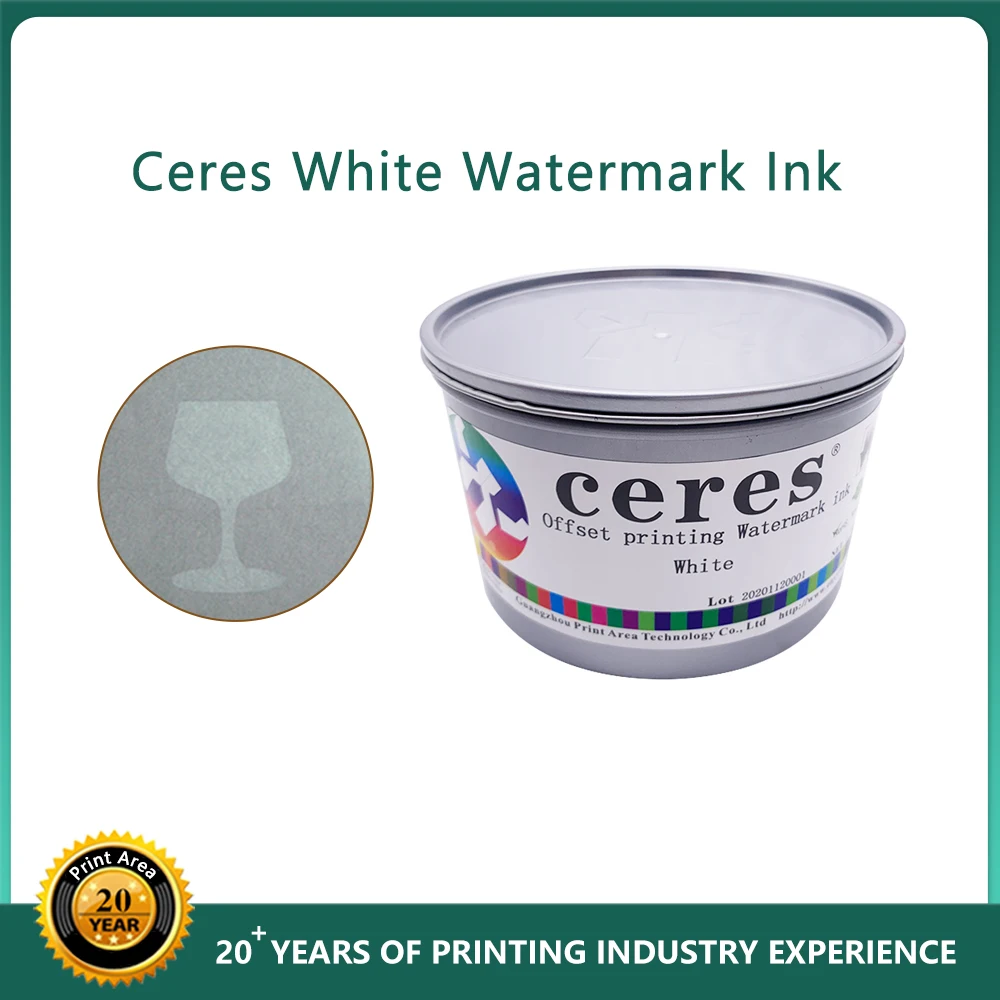

Product Name | Watermark Ink |

Printing Method | Offset |

Color | White |

Usage:

Print Area White Watermark- Offset Operation Guide

1,Suggest use new ink roller, or use reducer agent to cleanout the ink roller downright.(reducer agent 3-4 branches)

2,In order to make the ink don’t adhibit to machinery, every bisect printing machine must accede quarter wetting powder in water;

3,Such as printing effect is not ideal, can be used in the ink roller hair dryer blowing gently on a minute;

4,This ink will have a slight corrosion on the PS, such as the shutdown after a reboot to replace the PS, the printing more difficult, we must combine printing technology;

5,If the temperature is low not be appropriate to put ink, we can properly add offset watermark expert melody ink.

6,1 kg ink can be printed about 6,000 sheet of paper

Print Area Screen-White Watermark

1,Screen-White Watermark needs to add 300-500g solvent when printing ,mixing into aquiform ink.

2,advice : use 420 item screen printing , if dense, add to 30-50 thread.

3,1 kg ink can be printed about 1200 sheet of paper.

4.use 700 impregnant to dilution.

5,Must dry the impregnant for 3-5 hours after printing, or the ink will spread to make the lathework fuzzy.

Print Area Screen-Black Watermark

1,Screen-Black Watermark is printed between two pieces of carbon paper,use 350 item screen printing forme.

2,print on the back of paper if the paper is single-side , use 420 item screen printing forme.

3,so as to approach the effect of watermark paper ,can add to 30-50 thread on the edge of lathework.

4,use 700 impregnant to dilute.

Print Area White Watermark- Offset Operation Guide

1,Suggest use new ink roller, or use reducer agent to cleanout the ink roller downright.(reducer agent 3-4 branches)

2,In order to make the ink don’t adhibit to machinery, every bisect printing machine must accede quarter wetting powder in water;

3,Such as printing effect is not ideal, can be used in the ink roller hair dryer blowing gently on a minute;

4,This ink will have a slight corrosion on the PS, such as the shutdown after a reboot to replace the PS, the printing more difficult, we must combine printing technology;

5,If the temperature is low not be appropriate to put ink, we can properly add offset watermark expert melody ink.

6,1 kg ink can be printed about 6,000 sheet of paper

Print Area Screen-White Watermark

1,Screen-White Watermark needs to add 300-500g solvent when printing ,mixing into aquiform ink.

2,advice : use 420 item screen printing , if dense, add to 30-50 thread.

3,1 kg ink can be printed about 1200 sheet of paper.

4.use 700 impregnant to dilution.

5,Must dry the impregnant for 3-5 hours after printing, or the ink will spread to make the lathework fuzzy.

Print Area Screen-Black Watermark

1,Screen-Black Watermark is printed between two pieces of carbon paper,use 350 item screen printing forme.

2,print on the back of paper if the paper is single-side , use 420 item screen printing forme.

3,so as to approach the effect of watermark paper ,can add to 30-50 thread on the edge of lathework.

4,use 700 impregnant to dilute.

Why Choose Us

Business Card

FAQ

Q1:How long is the sample time of the shipper?Does the sample fee can be returned.

Proofing is usually 3-5 working days.If you order reach or exceed behind MOQ quantity,proofing fee refunded.If

not reached behind MOQ quantity,proofing fee will be taken by you.

Q2:About the sample what is the cost of transportation?

The freight depends on weight,packing size and your country or province region,etc.

Q3:Are you manufactory or trade company?

We are the Manufactory specialized in printing industry products for many years already,in

Guangzhou GuangDong province,China.

Also we have large warehouse and quality control department for purchasing products for

client.

Q4:How much the transportation freight of samples?

The freight depends on the weight and packing size and destination from here to your location.

Q5:How long can I expect to get the sample?

The sample will be ready for delivery in 3-

5 days.The samples will be sent via international express such as DHL,UPS,TNT,FEDEX an

d would be arrived within 3-5 days.

Proofing is usually 3-5 working days.If you order reach or exceed behind MOQ quantity,proofing fee refunded.If

not reached behind MOQ quantity,proofing fee will be taken by you.

Q2:About the sample what is the cost of transportation?

The freight depends on weight,packing size and your country or province region,etc.

Q3:Are you manufactory or trade company?

We are the Manufactory specialized in printing industry products for many years already,in

Guangzhou GuangDong province,China.

Also we have large warehouse and quality control department for purchasing products for

client.

Q4:How much the transportation freight of samples?

The freight depends on the weight and packing size and destination from here to your location.

Q5:How long can I expect to get the sample?

The sample will be ready for delivery in 3-

5 days.The samples will be sent via international express such as DHL,UPS,TNT,FEDEX an

d would be arrived within 3-5 days.