Шэньчжэнь производство печатных плат и сборка с

- Категория: Другие ПП и сборные ПП >>>

- Поставщик: Shenzhen,Moko,Technology,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.36 $* | 0.32 $* |

| Aug-17-2025 | 0.33 $* | 0.35 $* |

| Jul-17-2025 | 0.0 $* | 0.34 $* |

| Jun-17-2025 | 0.40 $* | 0.9 $* |

| May-17-2025 | 0.83 $* | 0.46 $* |

| Apr-17-2025 | 0.87 $* | 0.68 $* |

| Mar-17-2025 | 0.73 $* | 0.58 $* |

| Feb-17-2025 | 0.29 $* | 0.21 $* |

| Jan-17-2025 | 0.54 $* | 0.68 $* |

Характеристики

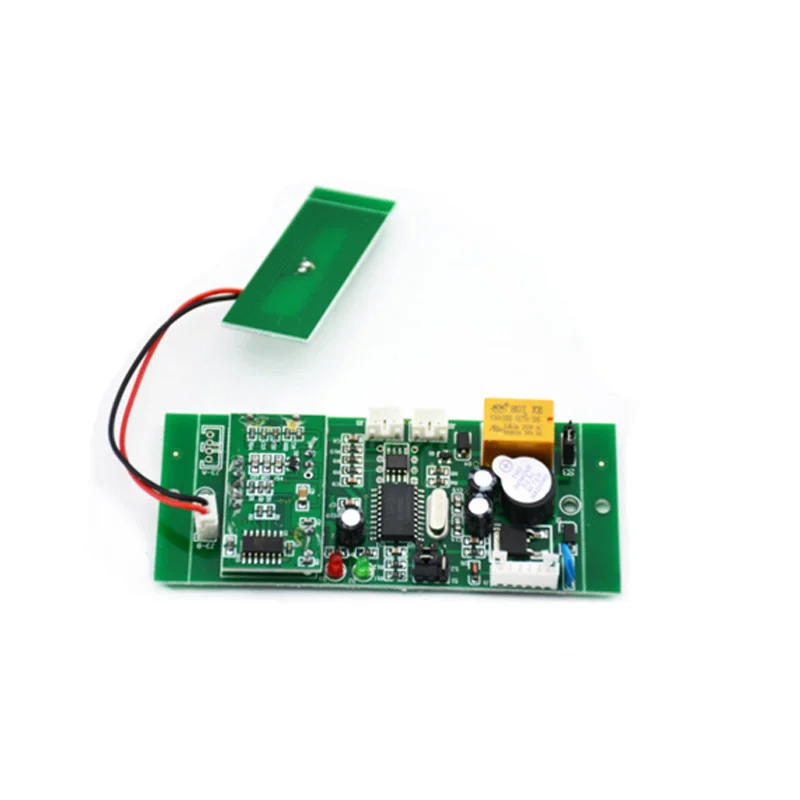

Shenzhen PCB Manufacture and PCBA Assembly with Component Sourcing

- Engineering Services

- PCB Assembly

- Component Procurement & Material Management

- Fast Track Prototyping

- Cable and Wire Assemblies

- Plastics and Molds

- Function Testing Service

Our PCB Sevices:

1. PCB fabrication.

2. Turnkey PCBA: PCB+components+SMT and through-hole assembly+enclosure molding&housing

Our Advantage:

1. Free programming and free functional test, free package.

2. High quality: IPC-A-610E standard, E-test, X-ray, AOI test, QC, 100% funtional test.

3. Professional service. ISO SMT and through hole assembly, over 10 years experience.

4. Certification for electronics: UL, 94v-0, CE, SGS, FCC, RoHS, ISO9001:2008, ISO14001

5. Warranty period for PCBA: 2 years.

*Fast Delivery:

PCB/PCBA Products 12Hours the fastest.

Provide the whole industry chain service,

From the pcb board, components purchase to pcb assembly,function testing and casing assembly.

*Engineering Support:

PCB file will be checked by our PCB engineer before production and PCBA will be test according to our engineering testing guide or

shared by clients.

*Customers Solutions:

Provide reasonable suggestion with the pcb files design and bom list choice to Enhance the competitiveness of product in the

markets.

Layers | Single Sided,2 to 18 Layer |

Board material type | FR4,CEM-1,CEM-3,ceramic substrate board, aluminum based board, high-Tg, Rogers and more |

Compound material lamination | 4 to 6 layers |

Maximum dimension | 610 x 1,100mm |

PCB assembly process: | Drilling-----Exposure-----Plating-----Etaching & Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function Testing-----Temperature & Humidity Testing |

Lead Time | Prototype: 15 work days. Mass order: 20~25 work days |

Files needed | PCB: Gerber files(CAM, PCB, PCBDOC) |

Components: Bill of Materials(BOM list) | |

Assembly: Pick-N-Place file | |

Passive Down to 0201 size | |

BGA and VFBGA | |

Leadless Chip Carriers/CSP | |

Double-sided SMT Assembly | |

Fine Pitch to 0.8mils | |

BGA Repair and Reball | |

Part Removal and Replacement | |

Min size: 0.25*0.25 inches(6*6mm) | |

Max size: 20*20 inches(500*500mm) | |

PCB Solder Type | Water Soluble Solder Paste, RoHS lead free |

Quantity | Min quantity: 1pcs. Prototype, small order, mass order, all OK |

Component package | Cut Tape,Tube,Reels,Loose Parts |

* Program Management

PCB Files → DCC → Program Organizing → Optimization → Checking

* SMT Management

PCB Loader → Screen Printer → Checking → SMD Placement → Checking → Air Reflow → Vision Inspection → AOI → Keeping

* PCBA Management

THT→Soldering Wave (Manual Welding) → Vision Inspection → ICT → Flash → FCT → Checking → Package → Shipment

Files Requested For Quote of PCB Assembly Services:

---In order to provide you with the most efficient and accurate quote on manufacturing the requested unit, we

ask that you provide us with the following information:

* Gerber file,PCB file,Eagle file or CAD file are all acceptable

* A detailed bill of materials (BOM)

* Clear pictures of PCB or PCBA sample for us

* Quantity and delivery required

* Test method for PCBA to guarantee 100% good quality products.

* Schematics file for PCB design if need to do function test.

* A sample if available for better sourcing

* CAD files for enclosure manufacturing if required

* A complete wiring and assembly drawing showing any special assembly instructions if required

Q: What files do you use in PCBA fabrication?

A: Gerber or Eagle, BOM listing, PNP and Components Position

Q:Is it possible you could offer sample?

A: Yes, we can custom you sample to test before mass production

Q: When will I get the quotation after sent Gerber, BOM and test procedure?

A: Within 6 hours for PCB quotation and around 24 hours for PCBA quotation.

Q: How can I know the process of my PCBA production?

A: 7-10 days for PCB production and components purchasing, and 10 days for PCB assembly and Testing

Q: How can I make sure the quality of my PCBAs?

A: We ensure that each piece of PCBA products work well before shipping. We'll test all of them according to your test procedure. Also if there are any defect items during the shipping, we also can be free to repair for you.