2600 автоматическая машина для склеивания коробок Киргизии Филиппин Узбекистана Малайзии Пакистана Южной Африки

- Категория: Gluing Machines >>>

- Поставщик: Hebei,Shengli,Paper,Chest,Equipment,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.28 $* | 0.29 $* |

| Aug-19-2025 | 0.57 $* | 0.43 $* |

| Jul-19-2025 | 0.59 $* | 0.5 $* |

| Jun-19-2025 | 0.6 $* | 0.49 $* |

| May-19-2025 | 0.40 $* | 0.7 $* |

| Apr-19-2025 | 0.46 $* | 0.32 $* |

| Mar-19-2025 | 0.49 $* | 0.90 $* |

| Feb-19-2025 | 0.82 $* | 0.65 $* |

| Jan-19-2025 | 0.75 $* | 0.68 $* |

Характеристики

2600 Automatic gluing stitching all-in-one machine

Technical specification

HEBEISHENGLI CARTON EQUIPMENT MANUFACTURING CO LTD

1、Machine features:

The machine is composed of vacuum paper feeding part and stapling part. Digital display control, PLC computer amplitude modulation, double frequency conversion synchronous operation, with simple, fast, reliable and accurate control mode, automatic paper feeding, automatic stitching and folding, automatic counting, automatic stacking output, high speed energy saving, labor cost saving.

2、Paper feeding department:

* Adopting the leading edge of the belt suction paper feeding way, accurate and reliable.

* Using high-grade electromagnetic clutch and electromagnetic brake system,so that the paper feeding part can be controlled independently,simple and reliable operation.

* The height of the press wheel can be adjusted.Suitable for cardboard thickness of 2-8mm.

* With the folding section linkage, frequency conversion speed regulation.

* The front baffle of the paper feeding department and the paper belt are adjustable.

3、Stapling department:

* Imported double servo driving,accurate,reduced mechanical transmission,can effectively prevent mechanical failure rate.

* Using touch screen operation,parameters (stitching distance, nail number, stitching type, tailgate) can be changed easily and quickly.

* The whole control system adopts Taiwan Yonghong PLC control system.

* All switches in the electric control box adopt Schneider brand.

* Bottom die、blade made of German tungsten steel (wear - resistant).

* The whole nail head is made of special steel and precision machined by computer.

* One minute size change, simple operation without experience, can stitch single nail, double nail, reinforcing nail.

* The paper feeding part counts automatically and sends out automatically after forming a bundle for easy binding.

* The nail distance can reach 100mm,can set on the display screen,can staple covered and uncovered carton.

* The cardboard thickness can be directly adjusted.

* Using touch screen operation,parameters (stitching distance, nail number, stitching type, tailgate) can be changed easily and quickly.

* The whole control system adopts Taiwan Yonghong PLC control system.

* All switches in the electric control box adopt Schneider brand.

* Bottom die、blade made of German tungsten steel (wear - resistant).

* The whole nail head is made of special steel and precision machined by computer.

* One minute size change, simple operation without experience, can stitch single nail, double nail, reinforcing nail.

* The paper feeding part counts automatically and sends out automatically after forming a bundle for easy binding.

* The nail distance can reach 100mm,can set on the display screen,can staple covered and uncovered carton.

* The cardboard thickness can be directly adjusted.

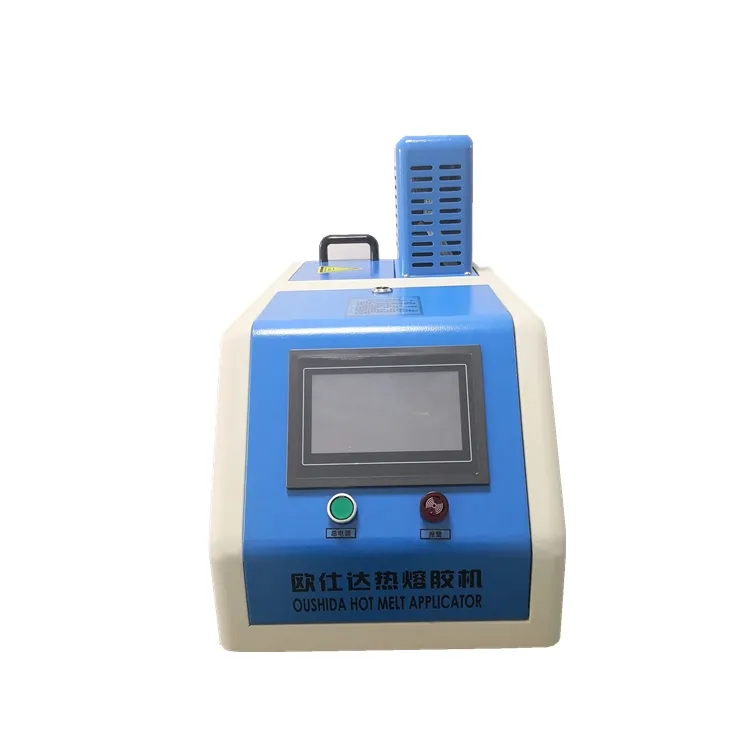

4、Automatic gluing part:

* Automatic gluing part adopts full electric control,automatically adjust the gluing position according to the size of the cardboard.

* The gluing width of the carton is 20-25mm, and the lower gluing method.

* The glue box can be moved left and right according to the type of carton.

* Gluing volume can be adjusted,stable,high capacity,easy to maintain.

* All the materials are pure stainless steel,never rust,resistant to various types of corrosion.

* The gluing width of the carton is 20-25mm, and the lower gluing method.

* The glue box can be moved left and right according to the type of carton.

* Gluing volume can be adjusted,stable,high capacity,easy to maintain.

* All the materials are pure stainless steel,never rust,resistant to various types of corrosion.

5、Automatic Folding Department:

* Automatic folding adopts full computer control,according to the size of the cardboard, automatically adjust the folding position and ganged with feeding unit,frequency control.

* Adopt imported high-friction belt and synchronous belt to transport paperboard,folding automatically,effectively avoid the phenomenon of scissors mouth caused by different cardboard thickness or different belt tightness on both sides.

* The feeding speed is synchronized with folding of the main machine, variable frequency speed regulation, can be controlled separately.

* After entering the size when replacing the product, It can be adjusted automatically. Convenient and fast.

* Indentation wheel, indentation knife, side wheel, slapping board, etc. can well control the occurrence of scissors mouth.

* Adopt imported high-friction belt and synchronous belt to transport paperboard,folding automatically,effectively avoid the phenomenon of scissors mouth caused by different cardboard thickness or different belt tightness on both sides.

* The feeding speed is synchronized with folding of the main machine, variable frequency speed regulation, can be controlled separately.

* After entering the size when replacing the product, It can be adjusted automatically. Convenient and fast.

* Indentation wheel, indentation knife, side wheel, slapping board, etc. can well control the occurrence of scissors mouth.

6、Parameter:

Max length (A+B)*2 | 2600mm | Power | 6HP |

Maximum size of A | 800mm | Machine length | 8100mm |

Minimum size of A | 200mm | Machine width | 3500mm |

Maximum size of B | 500mm | Machine weight | 3.7t |

Minimum size of B | 160mm | Machine speed | 50 pieces/min |

Max length(A+B)*2 | 2600mm | Stitching distance | 30-100mm |

Min length(A+B) | 720mm | Stitching number | 1-99 |

Max width(C+D+C) | 1300mm | Pressure requirements | 0.6Mpa |

Min width(C+D+C) | 300mm | Total power | 13.45KW |

Height of feeder | 500mm | Power consumption | 4.5Kw/H |

7、Successful Project

Russia

Nigeria

Mexico

America

England

Brazil

Korea

Egypt

Turkey

Thailand

Pakistan

South Africa

Italy

Singapore

India

The United Arab Emirates

Saudi Arabia

France

Indonesia

Greece

8、SIMILAR PRODUCTS

11、Why choose us