Otec Eco Maxi Магнитный стакан для ювелирных изделий магнитный магнитные

- Категория: Jewelry Tools & Equipment >>>

- Поставщик: Huzhou,Inovatec,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.34 $* | 0.4 $* |

| Aug-19-2025 | 0.41 $* | 0.0 $* |

| Jul-19-2025 | 0.33 $* | 0.37 $* |

| Jun-19-2025 | 0.74 $* | 0.40 $* |

| May-19-2025 | 0.55 $* | 0.40 $* |

| Apr-19-2025 | 0.80 $* | 0.74 $* |

| Mar-19-2025 | 0.48 $* | 0.0 $* |

| Feb-19-2025 | 0.73 $* | 0.55 $* |

| Jan-19-2025 | 0.3 $* | 0.33 $* |

Характеристики

Product Details & Optionals

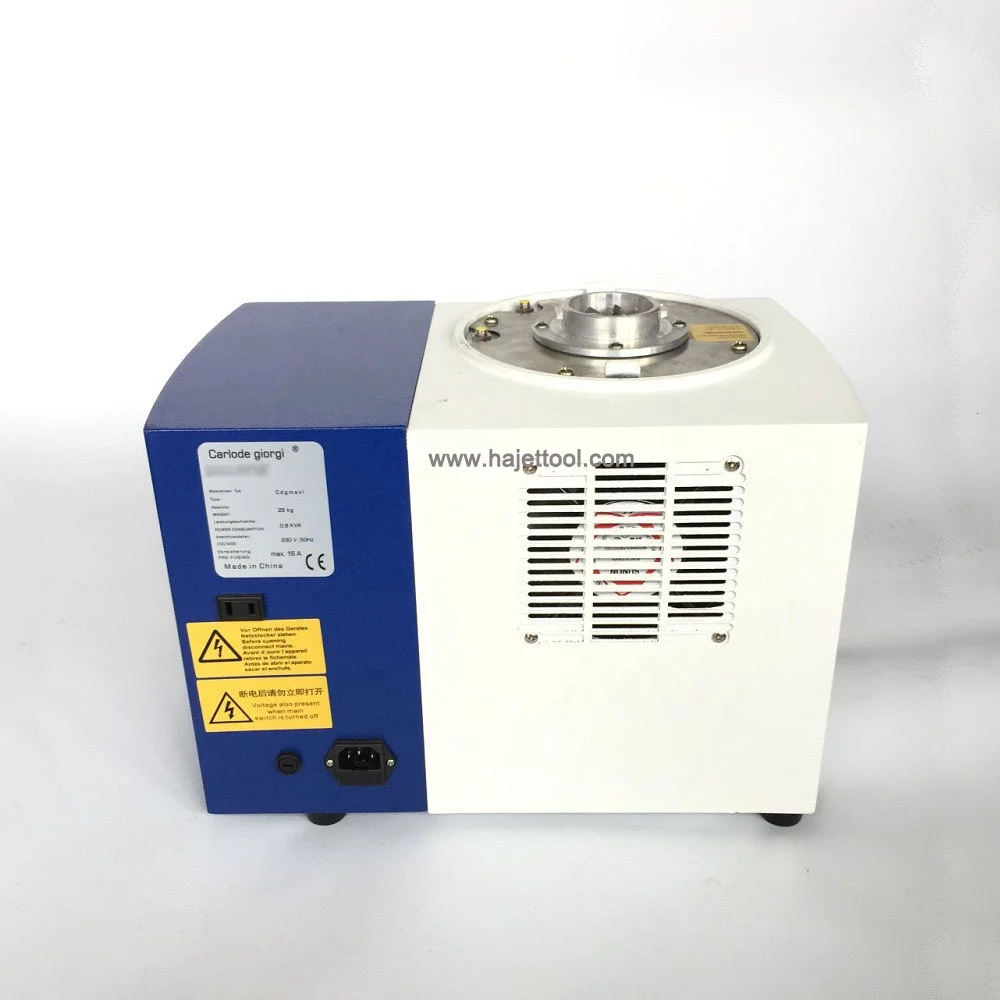

Benchtop Mini Centrifugal disc Otec Eco Maxi Price Magnetic polishing machine Jewelry polishing tools jewellery machine

Centrifugal barrel finishing machine Product Description:

Inovatec precision dics finishing machine offer a range of innovative disc finishing machines for large industrial and small

jewellery type applications.

The modular concept of the Inovatec ECO makes it ideal for small series production. Their high-tech design makes these machines extremely economical, with savings being as much as 60 % compared to the cost of conventional finishing. To cater for specific applications, the Inovatec ECO is available in the versions "magnetic", "wet" and "dry" and as a flexible all-rounder, the "basic" model.

jewellery type applications.

The modular concept of the Inovatec ECO makes it ideal for small series production. Their high-tech design makes these machines extremely economical, with savings being as much as 60 % compared to the cost of conventional finishing. To cater for specific applications, the Inovatec ECO is available in the versions "magnetic", "wet" and "dry" and as a flexible all-rounder, the "basic" model.

CLEAN AND BRIGHT WORKPIECE SURFACES

Completely removes any traces of sanding/grinding and casting skin for perfect results.

Completely removes any traces of sanding/grinding and casting skin for perfect results.

A SURFACE FINISH EQUAL IN QUALITY TO THAT OF MANUAL POLISHING

Puts a shine even on inaccessible areas of intricate workpieces and completely removes oxidation discoloration and any residual investment material.

Puts a shine even on inaccessible areas of intricate workpieces and completely removes oxidation discoloration and any residual investment material.

FLEXIBLE IN USE

This machine type is the first to use three separate or up to three different finishing processes in a single machine.

Grinding, deburring, smoothing, and polishing surfaces has always been regarded as painstaking and cost-intensive. At a very early stage, attempts were made to streamline the finishing process by means of technical aids. The drum process ranks among the most well-known techniques for surface finishing. It originated in the 18th century. In those days the items being polished were machined in a hollowed tree trunk by a filling of gravel and tidal flow.

Nowadays the drum process and vibrators are being increasingly superseded by systems such as the centrifugal disc finishing machine or the drag finishing machine, both of which have benefited from recent technological advances. They have proved to be extremely efficient, especially in the case of relatively small workpieces.

This machine type is the first to use three separate or up to three different finishing processes in a single machine.

Grinding, deburring, smoothing, and polishing surfaces has always been regarded as painstaking and cost-intensive. At a very early stage, attempts were made to streamline the finishing process by means of technical aids. The drum process ranks among the most well-known techniques for surface finishing. It originated in the 18th century. In those days the items being polished were machined in a hollowed tree trunk by a filling of gravel and tidal flow.

Nowadays the drum process and vibrators are being increasingly superseded by systems such as the centrifugal disc finishing machine or the drag finishing machine, both of which have benefited from recent technological advances. They have proved to be extremely efficient, especially in the case of relatively small workpieces.

Product Application

Aluminum machining parts before after deburring

aluminum parts before and after smoothing

automotive parts before and after deburring

bearing parts before and after polishing-min

brass precision parts before and after polishing-min

brass punched parts before and after polishing-min

brass retainer before and after polishing-min

carbon steel parts before and after deburring-min

Epoxy plastic parts before and after cleaning-min

service team & exhibition

Production process

Certifications

Cooperation partner

Payment and Shipment

FAQ

Q: How is Inovatec machinery brand?

Inovatec Machinery is famous Top 3 brand mass finishing equipment and consumables manufacturer of China, has:

- 25 years: vibratory finishing machines and tumbling media manufacturer experience.

- 20000 square meters factory

-2 year warranty

- 25 years: vibratory finishing machines and tumbling media manufacturer experience.

- 20000 square meters factory

-2 year warranty

Q: What Certifications do you have?

ISO9001, CE, certifications etc. 100% quality check, and testing before shipment.

Q: What is Inovatec Machinery equipment warranty?

2 year warranty for all Inovatec Machinery equipment

Lifetime maintenance will be provided after the 2 year warranty period expires.

Lifetime maintenance will be provided after the 2 year warranty period expires.

Q: How you guarantee tumbling media quality?

We make quality tracking from raw material until quality check before shipment. We keep record of quality test including wearing and cutting.

For bulk and OEM order, we follow your testing methods and keep track of wearing and cutting. If the quality does not meet the standard, we will not make the shipment.

For bulk and OEM order, we follow your testing methods and keep track of wearing and cutting. If the quality does not meet the standard, we will not make the shipment.

Q: What is your Payment method?

Accept payment via T/T (Bank transfer), Western Union, Money Gram, and PayPal;

Accept L/C at sight (bulk order).

Accept L/C at sight (bulk order).

Q: What is your Minimum order amount?

For machine minimum order is 1 PCS. For tumbling media minimum order is 1000kg or 2000 lbs as one pallet.

You can ship less amount of media if ship with the machine.

Sample order is allowed to ship less amount of tumbling media

You can ship less amount of media if ship with the machine.

Sample order is allowed to ship less amount of tumbling media

Q: What is your way of packaging?

Fermentation wooden pallets for media, 1000kg per pallet, 25kg/plastic bag

Customize packaging and logo printing is available for discuss

Wooden box for equipment and compound

Customize packaging and logo printing is available for discuss

Wooden box for equipment and compound

Q: How long is your production time?

15 working days for sample order;

20-25 working days for bulk order.

Emergency order can be fulfilled in a week

20-25 working days for bulk order.

Emergency order can be fulfilled in a week

Q: What is the Shipping Way?

20-30 days by sea to your nearest seaport

2-5 days by air to your nearest airport

3-5 days by express to your doorstep

2-5 days by air to your nearest airport

3-5 days by express to your doorstep

Q: What is the nearest Port:?

Shanghai, Ningbo and Yiwu are the closest port.