Xinren низкая цена DN15-DN500l испаритель и конденсатор Теплообменный аппарат плиты изолированной Уплотнительной

- Категория: Refrigeration & Heat Exchange Parts >>>

- Поставщик: Shandong,Xinren,Environmental,Protection,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.83 $* | 0.3 $* |

| Aug-17-2025 | 0.33 $* | 0.3 $* |

| Jul-17-2025 | 0.49 $* | 0.41 $* |

| Jun-17-2025 | 0.45 $* | 0.25 $* |

| May-17-2025 | 0.4 $* | 0.25 $* |

| Apr-17-2025 | 0.72 $* | 0.90 $* |

| Mar-17-2025 | 0.16 $* | 0.29 $* |

| Feb-17-2025 | 0.69 $* | 0.3 $* |

| Jan-17-2025 | 0.93 $* | 0.98 $* |

Характеристики

Xinren Low Price DN15-DN500l Evaporator and Condenser Heat Exchanger plates and gasket

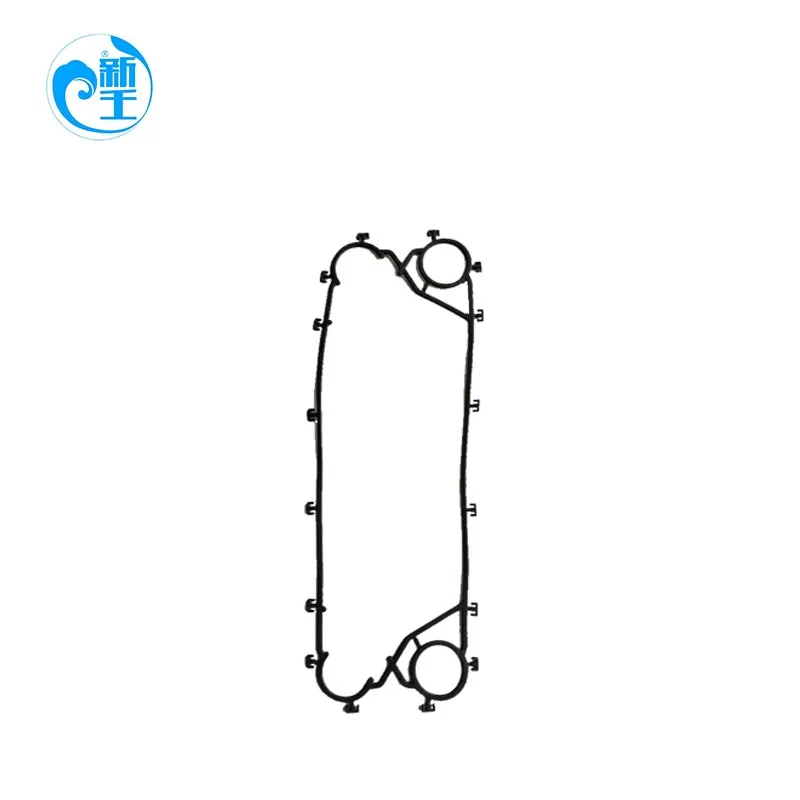

The plate heat exchanger consists of a pack of corrugated metal plates with portholes for the passage of the two fluids between which heat transfer will take place. The plate pack is assembled between a fix frame plate and a movable pressure plate and compressed by tightening bolts. The plates are fitted with a gasket which seals the inter plate channel and directs the fluids into alternate channels. The number of plates is determined by the flow rate, physical properties of the fluids, pressure drop and temperature program. The plate corrugations promote fluid turbulence and support the plates against differential pressure. The frame plate and the pressure plate are suspended from an upper carrying bar and located by a lower guiding bar, both of which are fixed to a support column. Connections are located in the frame plate or, if either or both fluids make more than a single pass within the unit, in the frame and pressure plates.

We can supply whole set plate heat exchanger, plate, gaskets of following models

| AL | M3 M6B M6M TL6B TS6 M1OB M10M TL10B TL10P M15B M15M T20M T20B T20P TS20 AK20 MX25M MX25B M30 P16 P26 P36 TL35B CLIP6 CLIP8 CLIP10 CLIP15 M6MW M10BW MK15BW M20BW M30BW MA30S MA30W AX30B MA30 TL15B T2B T5B T5M |

| APV | H12 H17 N35 N40 N50 SR14GD R8GI TR9-III TR9-II TR9-I TR9 Q030E Q030 Q055 Q080 A055 A085 J060 J092 J107 J185 A145 M107 M092 M060 R14 R5 |

| Tranter | GC008 GL13 GX18 GC16 GC26 GX26 GX42 GX51 GC51 GC60 GX60 GX100 GX140 GX64 GX91 GX118 GX85 GX145 |

| GEA | VT04 VT10 VT20 VT40 VT40M NT50M NT50X VT405 VT80 VT80M VT80P NT100T NT100M NT00X NT150L NT150S NT250S NT250M NT250L NT350S NT350M VT2508 A184 N40 A161 |

| Sondex | S4A S8A S7A S14A S9A S19A S31A S17 S20A S21A S22 S37 S41 S42 S43 S65 S100 S47 S64 S81 S121 S62 S110 SF160 SF123 |

| Vicarb | V4 V8 V13 V20 V28 V45 V60 V100 V110 V130 V170 V280 |

| Funke | FP04 FP05 FP08 FP09 FP10 FP16 FP22 FP14 FP20 FP31 FP40 FP50 FP71 FP205 FP41 FP60 FP80 FP112 FP130 |

| Sigma | Sigma13 Sigma26 Sigma36 Sigma56 Sigma66 Sigma156 Sigma55 SigmaM35 SigmaM25 SigmaM36 SigmaM106 SigmaM90 |

| Gasket Material | Operating Temperature | Sultable Media |

| NBR | -20℃-+110℃ | Water,sea water,mineral oil,Salt,Brine |

| EPDM | -50℃-+150℃ | Hot water steam,Acid,Alkali |

| HNBR | -15℃-+160℃ | High temperature,mineral oil,water |

| VITON/FKM | -35℃-+180℃ | High temperature,high resistance,strong oxidans,oil,acid,alkali,etc |

| Plate Material | Suitable Media |

| Stainless Steel(304/316) | Pure Water, River Water, Edible Oil, Mineral Oil |

| Ti, Ti-Pd | Seawater, Brine, Salt Substance |

| 20Cr,18Ni,6Mo(254MO) | Dilute Sulfuric Acid, Dilute Salt Substance Aqueous Solution, Inorganic Aqueous Solution |

| Ni | High Temperature, High Density Caustic Soda |

| Hastelloy(C276,D205,B2G) | Concentrated Sulfuric Acid, Hydrochloric Acid, Phosphoric Acid |

According to industry custom, does not include the plate shape as the surface of the last two categories, only the plate shape for rectangular or round corrugated plate of the first two categories, further divided into:

1. According to the connection between the plates is divided into removable or sealed straps and welding plate heat exchangers.

2. According to the runner characteristics of cold and hot fluids or plate structure can be divided into symmetrical plate heat exchangers and asymmetric plate heat exchangers.

3. According to the gap size of the runner can be divided into: conventional gap plate heat exchanger and wide gap plate heat exchanger.

4 according to the complete set of products can be divided into: plate heat exchanger single machine and plate heat exchanger unit.

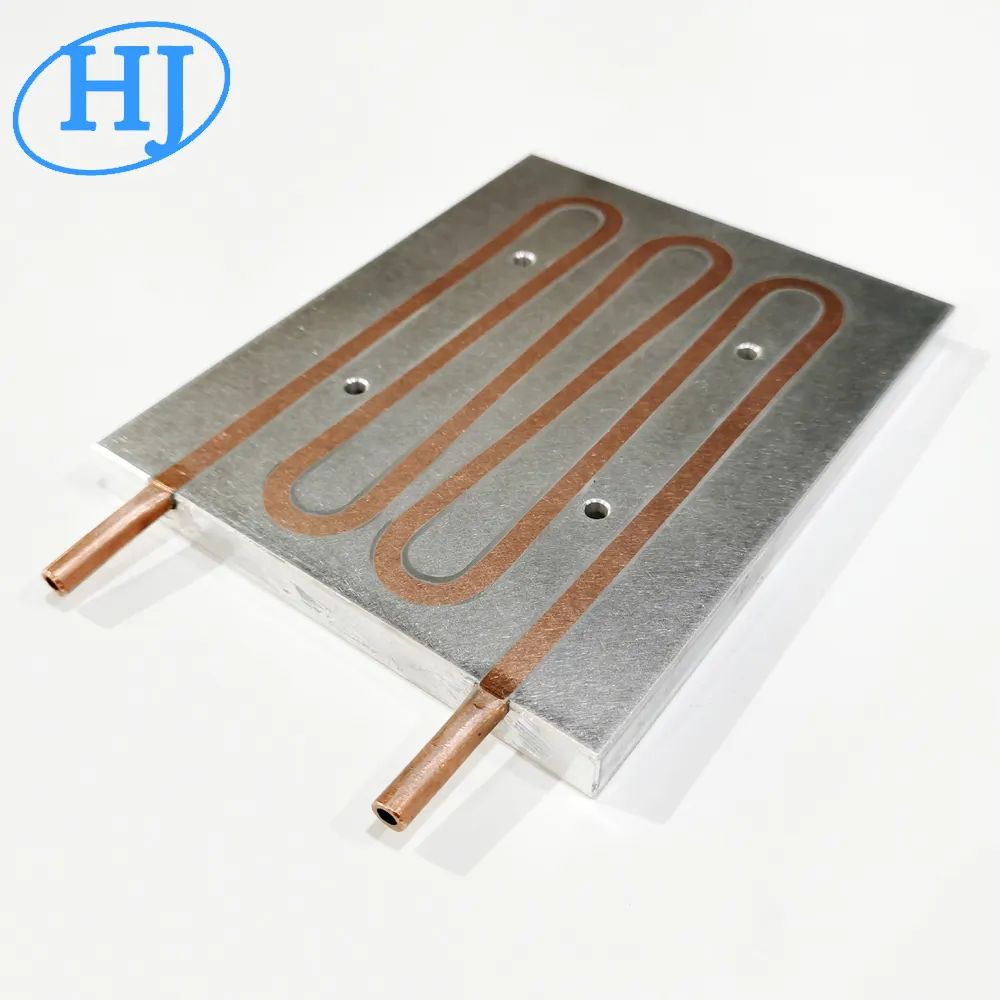

Heat transfer plate is the main heat exchanger heat exchanger components, general ripples into human glyphs, according to the fluid medium, heat transfer plate material is not the same, mostly made of stainless steel and titanium.

The gaskets of the plate heat exchanger are mainly sealed between the heat exchangers. Materials are: butyl rubber, triethyl propylene rubber, fluoro-rubber, etc. , according to different media using different rubber.

The heat transfer coefficient is 3 to 10 times larger than the tube shell heat exchanger, the compact structure, light, the heat transfer area per unit volume can reach 2500 to 4370m2/m3; Can be used for gas-gas, gas-liquid and liquid-liquid heat exchange, can also be used for condensation and evaporation, suitable for many different fluids in the same equipment operation, the selection of suitable materials can be used for heat exchange of various temperature ranges from 0 to 1000K, aluminum materials are particularly suitable for low or ultra-low temperature scase, complex structure, high cost, low runner, easy to clogging , not easy to clean, difficult to access, etc.

The strengthening of heat transfer process of heat exchanger 1. Increase heat transfer area method: increase the heat transfer area within the unit volume, use small tube diameter, plate heat exchange surface, change the shape of the heat transfer surface, etc.; High efficiency and compact results. 2. Improve the heat transfer force of the tm method: the average temperature difference of the size of the tm mainly depends on the temperature conditions of the two fluids, often limited by the process conditions. However, the temperature of the heating agent or coolant can vary greatly depending on the choice, such as the appropriate increase in the heating steam pressure, reduce the cooling water inlet temperature, determine the appropriate export temperature can be increased. When the two fluids do not change phase, the operation of the reverse or near countercurrent from the structure as far as possible can be improved. 3. Increase heat transfer coefficient K method: reduce dirt heat resistance: by increasing the flow rate to flush the wall of the pipe to prevent dirt deposits, or the use of scale inhibitors and other chemical and mechanical methods to inhibit the generation speed of dirt, and pay attention to timely removal and other measures. Improve the coefficient of circulation heat: especially the heat coefficient of the spread on the small side of h, the main way is to increase the degree of turbulence and reduce the thickness of the layer flow bottom. Specific measures are: (1) increase the flow rate, increase the number of Renault. Such as increasing the number of tube strains in the column tube heat exchanger and adding a bezel in the tube; Such as flow ingress in the shape tube or set up additives in the tube, the use of corrugated or rough surfaces, so that the flow direction and size of continuous change, etc. , can improve the heat transfer intensity; The jet heat transfer surface is caused by the jet method. Development at home and abroad overview: hemp flat tube heat exchanger: due to the unique tube structure of the tube and shell course to promote turbulence. The heat transfer coefficient of the heat exchanger is called an increase of 40% for the existing heat exchanger, while the pressure drop is almost equal. Features: improved heat transfer, reduced dirt, real reverse flow, no vibration, space saving, no folding elements, reduced costs.

Packing is one of the most important pre sale precaution to guarantee the customers when receive the good intact,

Xinren carrys out a clear method to dismiss customer concerns about maritime transport

| Product | Packing Method | Container Loads |

| Plate Exchanger | Plywood case for each set / pcs | 20/40 GP & HQ, FCL & LCL |

| Tube Exchanger | Plywood case for each set / pcs | 20/40 GP & HQ, FCL & LCL |

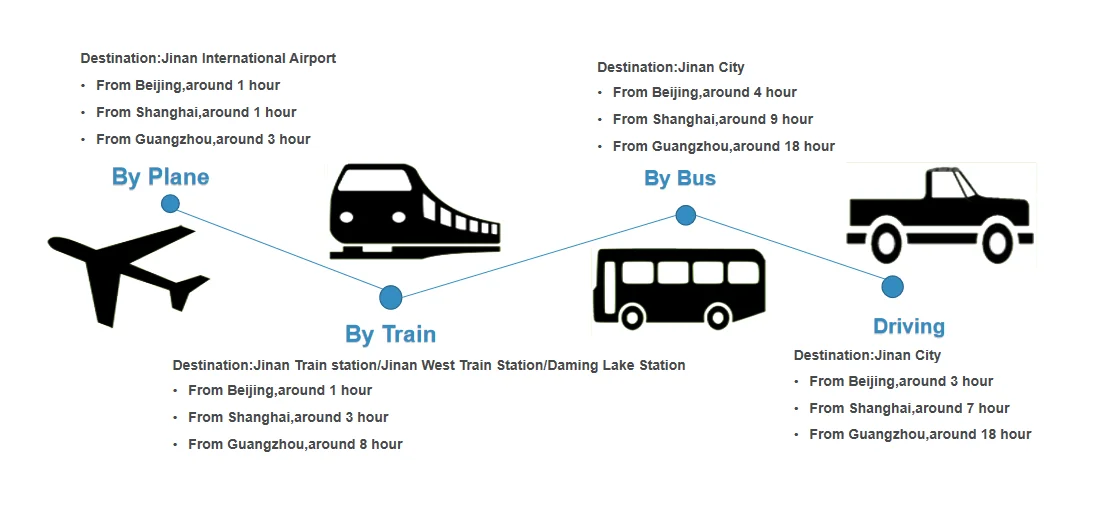

Since 1997, Xinren has begun deep developing heat exchanger area for more than 20 years!

This is the FACTORY OF XINREN located in Jinan, over 53819.55ft²

Xinren devoted huge mount of found to equip most advanced production lane to ensure we can meet customers` request:

No matter

QUANTITY

or

QUALITY!

XINREN!

QUANTITY & QUALITY PRODUCER OF HEAT EXCHANGER!

This is the 150ton cold presser to make heating plates

Semi assembled heat exchanger

1, plate selection plate type or ripple form should be based on the actual needs of the plate heat exchanger application. For the large flow allow pressure drop small situation, should choose the small resistance of the plate type, the opposite choice of large resistance plate type. Depending on the fluid pressure and temperature, determine whether you are able to choose a removable or brazing type.

It is not appropriate to select the plate area is too small when determining the plate type, so as not to have too many plates, the flow rate between the plates is too small, and the heat transfer coefficient is too low.

2, pressure down school core in Kangjinghui plate heat exchanger design selection, pressure drop is also a certain requirement, so it should be nuclear.

If the check-in nuclear pressure drop exceeds the allowed pressure drop, the design selection calculation needs to be re-calculated until the process requirements are met.

3, process and runner selection Process refers to a set of parallel runners in the same flow direction of a medium in a heat exchanger, while a flow channel refers to a medium flow channel consisting of two adjacent plates in the current channel. In the process of plate heat exchanger selection, the process combination form should be calculated according to heat exchanger and fluid resistance, and be determined according to the requirements of the process conditions. Try to make the convection heat exchange coefficient in the cold and hot water runner equal or close, so as to obtain the best heat transfer effect.

Because the convective heat exchange coefficient is equal or close on both sides of the heat transfer surface, the heat transfer coefficient is obtained a larger value.