Установка для переработки соли методом вакуумной кристаллизации

- Категория: Extractor >>>

- Поставщик: Jiangsu,Hanpu,Mechanical,Technology,Co.,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.0 $* | 0.33 $* |

| Aug-19-2025 | 0.55 $* | 0.1 $* |

| Jul-19-2025 | 0.77 $* | 0.53 $* |

| Jun-19-2025 | 0.79 $* | 0.54 $* |

| May-19-2025 | 0.7 $* | 0.84 $* |

| Apr-19-2025 | 0.18 $* | 0.95 $* |

| Mar-19-2025 | 0.5 $* | 0.32 $* |

| Feb-19-2025 | 0.65 $* | 0.68 $* |

| Jan-19-2025 | 0.89 $* | 0.16 $* |

Характеристики

Product Description

Salt refinery plant by vacuum crystallization process with MVR method

Mechanical vaporization re-compression system, which is called MVR which principle is to compress the second steam generated by evaporator by high efficiency steam compressor; this process transfers electric energy to eating energy and higher the pressure and temperature of second steam. The second steam with higher temperature will be sent to evaporation room to heat the product for evaporation. So the latent heat of vaporization of the second steam can be circularly used. Making use of less energy which is the mechanical energy of compressor blade wheel as the compression heat pump, energy is added into the heating medium and is circularly used in heating process. Under this circumstance, no need to add first steam as heating medium.

MVR SYSTEM ADVANTAGE

(1)Lowest energy consumption and operation cost, electricity consumption of one ton water’s evaporation is 15-50kw.

(2)Temperature difference is small, heating is gentle, the loss of product is less.

(3)Compact structure and lower building cost; plant area is 50% less than that of traditional evaporator.

(4)Surrounding is friendly, no gas and no steam.

(5)Good adaptability in low loading condition, flexibility of operation is good and has a longer service life.

(6)Consumption of circular water is low and energy saving is obvious.

(7)No fresh steam is needed.

(8)Evaporation can be carried out under 40℃ and equipment need not to be frozen, specially suitable for thermal activity products.

MVR System Application

Environmental Protection IndustryChemical Industry

Food Industry

Other Industry

Food Industry

Other Industry

MVR System Main Evaporator Flow

Falling Film: 20-45kwh/ton water.Forced Circulation: 30-60kwh/ton water.

Climbing Film:15-40kwh/ton water.

Climbing Film:15-40kwh/ton water.

Customer Site

Packing & Delivery

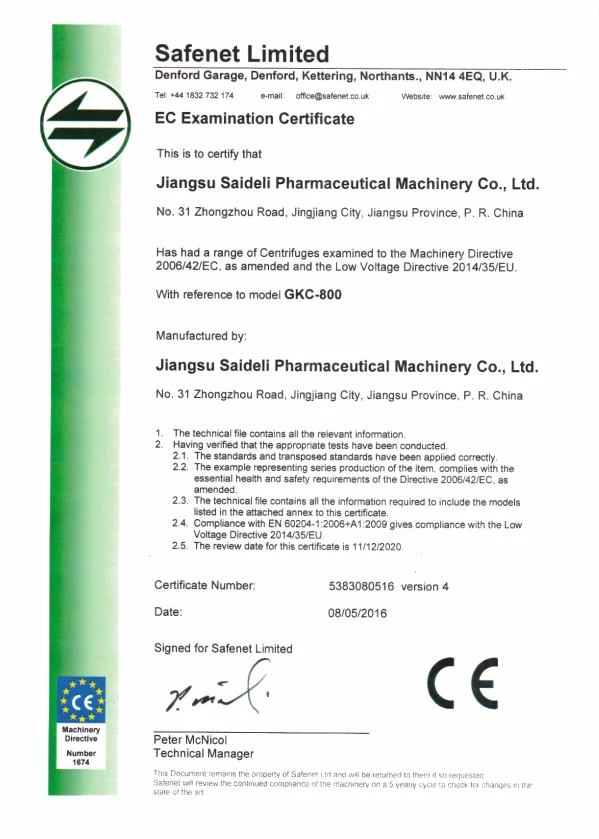

Certifications

Our Exhibition

FAQ

1. How do you protect the quality?

- As state owned enterprise with more than 100years history, we have strict operation policy,advanced processing machines to guarantee the precision, workers with operation license, related components are from world famous brand, Series of test and inspection are done in the whole producing stage.

2. What is your advantage compared with your competitors?

- Quality and experience, we are top centrifuge supplier in China,our designs and structures are analogous to world leader brands.

3. Is your price competitive?

- My price is not the lowest in China, but we promise, for the same quality and collocation, my price is the most favorable, for the same price, my quality is definitely superior to other brands.

4. Will you dispatch technicians for installation and commissioning?

- Yes, we will upon required.

5. Do you have OEM service? Do you supply the parts?

- Yes, we do, as long as you provide us your drawing and detailed requirements.

6. Do you have agents or service centre abroad?

- We have some partnership in several countries as Indonesia, Brazil, USA.

7. How can we visit your factory?

- If you come from aboard, air to shanghai or Nanjing airport, or if you arrive shanghai, you can take bullet train.

- If you come from domestic city, air or train directly to Nanjing Nan or WUXI east, we will pick you up both from airport or railway station.

8. Can we visit your end user or contact them?

- Yes, we will provide you the name list, and arrange the visit after their approval.

- As state owned enterprise with more than 100years history, we have strict operation policy,advanced processing machines to guarantee the precision, workers with operation license, related components are from world famous brand, Series of test and inspection are done in the whole producing stage.

2. What is your advantage compared with your competitors?

- Quality and experience, we are top centrifuge supplier in China,our designs and structures are analogous to world leader brands.

3. Is your price competitive?

- My price is not the lowest in China, but we promise, for the same quality and collocation, my price is the most favorable, for the same price, my quality is definitely superior to other brands.

4. Will you dispatch technicians for installation and commissioning?

- Yes, we will upon required.

5. Do you have OEM service? Do you supply the parts?

- Yes, we do, as long as you provide us your drawing and detailed requirements.

6. Do you have agents or service centre abroad?

- We have some partnership in several countries as Indonesia, Brazil, USA.

7. How can we visit your factory?

- If you come from aboard, air to shanghai or Nanjing airport, or if you arrive shanghai, you can take bullet train.

- If you come from domestic city, air or train directly to Nanjing Nan or WUXI east, we will pick you up both from airport or railway station.

8. Can we visit your end user or contact them?

- Yes, we will provide you the name list, and arrange the visit after their approval.